The Modicon M580 PLC is Schneider Electric’s rack-based controller built for connected control systems. Many engineers call it an ePAC because it keeps PLC-style determinism, but treats Ethernet as a first-class part of the architecture, not an add-on card.

In practice, it fits both machine control and process control. It’s common in water plants, energy systems, and large production lines where downtime hurts. This guide is for maintenance techs, controls engineers, and plant managers who need a clear picture of what the M580 does, what it doesn’t, and what to plan for.

People choose it for three reasons: built-in Ethernet that simplifies networks, strong uptime options like redundancy, and easier access to controller data for SCADA, historians, and troubleshooting.

What the Modicon M580 PLC is, and what makes it different from a classic PLC

![]() An example of a rack-based PLC system with Ethernet connectivity.

An example of a rack-based PLC system with Ethernet connectivity.

At a hardware level, the M580 is a modular controller in the Schneider Electric X80 family. You build it like a traditional rack system, with a power supply, CPU, and I/O modules. The difference shows up in how the system moves data. Instead of treating Ethernet as a bolt-on network, the M580 uses an Ethernet backplane concept that’s meant to keep I/O, peer devices, and tools on a consistent network path.

That design matters because it reduces gateways and protocol translations. Fewer conversion points usually mean fewer “mystery” failures at 2 a.m. It also makes diagnostics faster because you can trace network health and device status in a more direct way.

For a manufacturer’s description of models and positioning, see Schneider Electric’s Modicon M580 PAC controller overview.

Ethernet is built in from the start, not added on later

Most M580 CPUs provide dual Ethernet ports, and some models support 1 Gbps at the CPU interface. More important than raw speed is the architecture: Ethernet connectivity reaches deeper into the platform, so you spend less time designing “side networks” just to get data out.

As a result, it’s easier to connect HMIs, SCADA servers, historians, and engineering workstations without extra hardware. Many plants also use standard industrial protocols on Ethernet, which can lower integration time when you add drives, remote I/O islands, or smart instruments.

If you want a high-level summary from an automation publisher, Interesting Automation has a quick breakdown of the key features of Modicon M580.

Performance, memory, and I/O scale, what it can realistically handle

The M580 targets medium-to-large systems. Across common CPU models, published specs include program RAM in the rough 8 to 24 MB range, plus expandable flash storage up to about 4 GB. That headroom helps when you keep large libraries, recipes, trends, or diagnostic buffers.

On the I/O side, many typical configurations support up to about 4096 discrete points or 1024 analog points locally, plus multiple remote racks depending on architecture and CPU. In plain terms, it’s comfortable handling thousands of signals while still leaving room for communications, diagnostics, and time-stamped events.

X80 modules cover the usual needs (discrete, analog, comms), plus specialty modules such as counters and process-focused I/O. So, you can start with a mid-size rack today and expand without switching controller families later.

Key features you will care about on day one (networking, uptime, safety, and security)

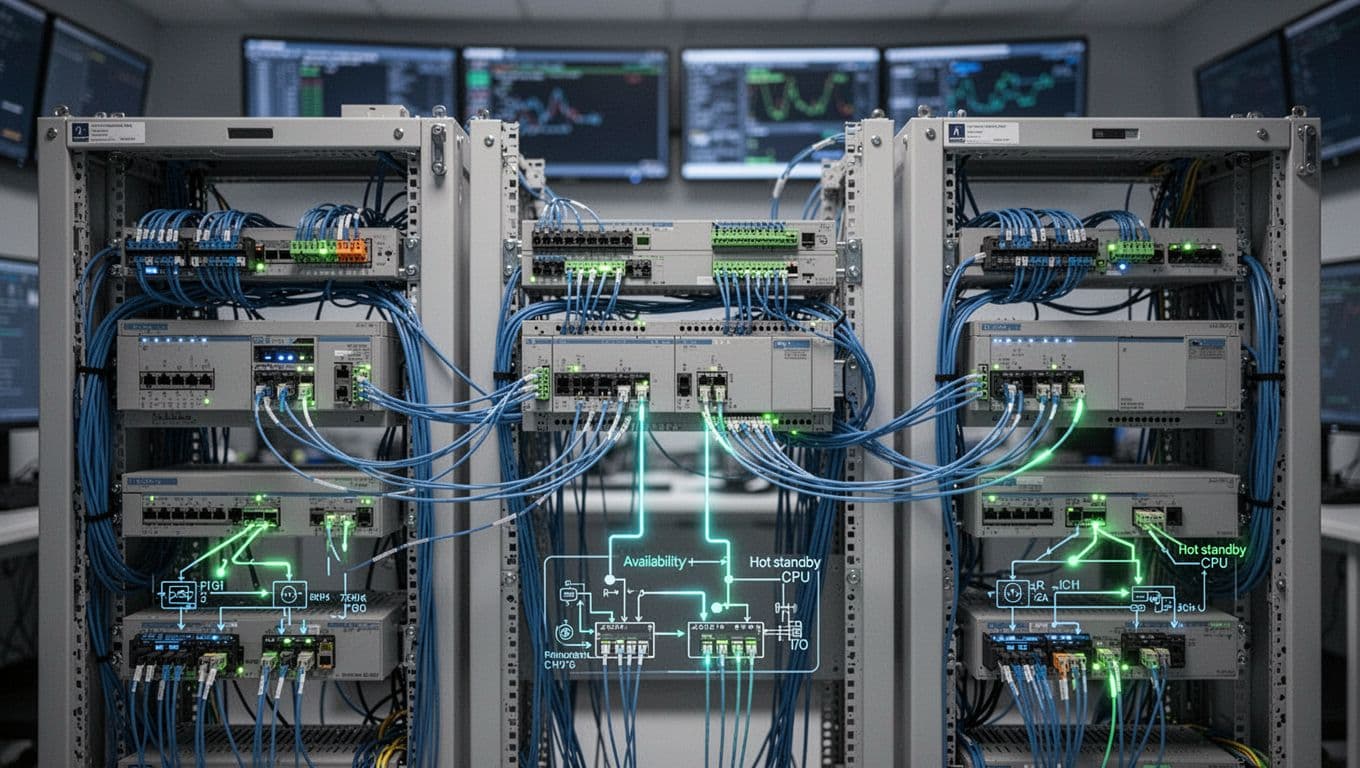

An example of a redundant Ethernet architecture with local and remote racks.

An example of a redundant Ethernet architecture with local and remote racks.

Specs look nice on paper, but day-one value is about uptime and support. The M580 family focuses heavily on keeping the controller online, keeping comms stable, and making faults easier to isolate.

If a control platform can’t tell you what happened and when, you end up troubleshooting by guesswork. Prioritize event history and time sync early.

High availability options, hot standby redundancy, and hot-swapping I/O

For high availability, M580 supports hot standby architectures, meaning you can run two CPUs where one takes control if the other fails. In well-designed systems, that switchover can occur without a process stop. Some redundancy links can run over fiber, and published options allow long distances (commonly cited up to about 15 km), which helps on spread-out sites like water districts or pipeline facilities.

Hot-swapping is another practical win, but it needs planning. Not every module swap is “no-risk,” and your wiring strategy matters. Still, when the system and procedures support it, replacing a failed I/O module without shutting down the whole rack can save hours.

An example of a module replacement workflow in a rack system.

An example of a module replacement workflow in a rack system.

Safety and cybersecurity basics: what the built-in protections do

For safety-rated applications, the M580 line includes safety models and architectures that support SIL3 setups, which matters in risk-heavy processes and machines. Safety is never “set and forget,” but having a controller family that supports safety planning can simplify standardization across a site.

Cybersecurity matters just as much, because Ethernet-first control means more pathways into the controller. The M580 platform supports protections that can include firewall functions and secure communications options, depending on model and design. Even so, default settings won’t match your plant’s risk profile.

A simple baseline checklist to start with:

- Change default credentials and limit who can program online.

- Close unused ports and turn off services you don’t need.

- Segment networks (controls vs business vs vendor access).

- Keep firmware current and track what version is installed.

For deeper configuration and reference material, Schneider Electric publishes a detailed Modicon M580 user guide.

How do you engineer and maintain an M580 system without surprises

Photo by Sean P. Twomey

Most M580 problems don’t come from the CPU. They come from layout choices, network design, and support habits. So, it helps to think in a simple lifecycle: select hardware, design networks, program, test, then support.

Choosing the right hardware layout, racks, X80 modules, and remote I/O

Start with signal count and signal type, then map that to X80 modules and racks. Next, decide what must live in the local cabinet and what can sit as remote I/O near the equipment. Because the M580 architecture is Ethernet-focused, you can often keep local and remote I/O on a consistent network approach, which cuts wiring back to the main cabinet.

Environmental ratings help, but cabinet design still matters. Heat, noise, and grounding issues can cause intermittent faults that look like “network problems.” Plan for clean 24 VDC power, solid bonding, and separation from high-noise sources such as VFD output wiring.

Programming and diagnostics with EcoStruxure Control Expert (Unity Pro)

You engineer M580 systems in EcoStruxure Control Expert (often still called Unity Pro). It supports common IEC 61131-3 languages such as Ladder, Function Block Diagram, and Structured Text. Online changes and forcing tools are part of the normal workflow, which helps when you need to correct logic without long outages.

Diagnostics are where teams feel the benefit. Many M580 setups support event time stamping down to about 1 ms, which helps you reconstruct a trip sequence instead of guessing. Some models also expose web-style status pages for quick checks, which can shorten “walk up and see” time during outages.

M580 vs M340 and Quantum, when it is the right upgrade and when it is not

This quick table frames the choice for most plants.

| Decision point | M580 | M340 | Quantum (legacy) |

|---|---|---|---|

| Ethernet-first design | Strong fit | Often add-on dependent | Commonly upgrade-driven |

| Uptime options | Hot standby available | More limited | Depends on installed base |

| Data access and diagnostics | Strong fit | Good for smaller systems | Varies by vintage |

| Best fit | Medium to large systems | Small to mid systems | Existing fleets, staged migration |

In short, the M580 earns its cost when Ethernet density, uptime goals, and support speed matter more than minimal hardware spend.

When the M580 is the smart pick (and common use cases)

The M580 makes sense when you have many Ethernet devices, distributed I/O, and a real cost to downtime. It’s common in water and wastewater, oil and gas, power and energy systems, and large packaging lines. It also fits plants that need tight event tracking for trips, quality holds, or batch sequencing.

Schneider Electric also shares background on the platform’s evolution in Modicon M580 history and use cases.

When an M340 or a legacy Quantum setup may still make sense

A small standalone machine with limited I/O and little networking doesn’t need an M580. Budget and support skills matter too. If the plant can’t support the engineering toolchain or network discipline, a simpler controller can reduce risk.

For upgrades, plan for more than a CPU swap. Migration often involves downtime scheduling, network re-design, and training. A third-party perspective can help when scoping differences, like this M340 vs M580 technical comparison.

Conclusion

The Modicon M580 PLC stands out because it treats Ethernet as core infrastructure, not a side feature. It scales to large I/O counts, supports strong uptime designs, and improves diagnostics when time and sequence matter. Still, it only pays off if you plan safety and security like engineering requirements, not afterthoughts.

Next step: write down your I/O count, uptime target, and the list of Ethernet devices you must support. Then map those needs to an M580 rack layout, remote I/O plan, and network segmentation strategy.