The Modicon M580 is a high-performance Programmable Automation Controller (PAC) from Schneider Electric. It is designed for complex and demanding industrial automation applications. Here are some key features and benefits of the Modicon M580:

Key Features:

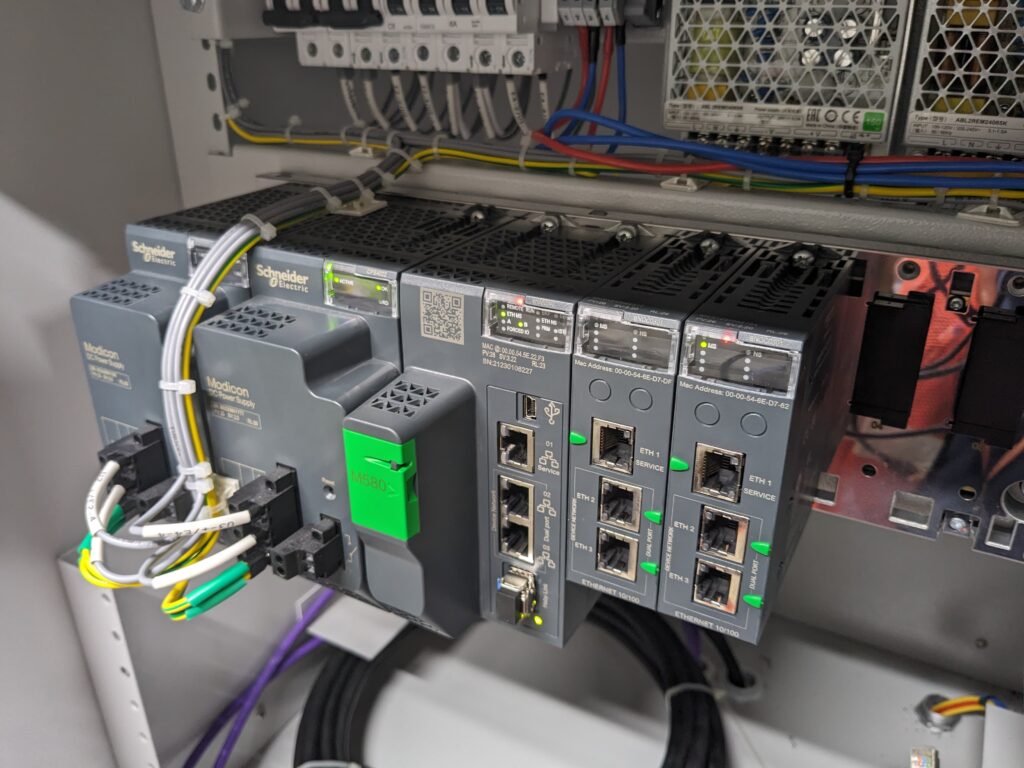

- High Processing Power: The M580 offers advanced processing capabilities for handling large and complex control tasks.

- Ethernet-Based Communication: It supports Ethernet communication natively, facilitating faster and more reliable data transfer and integration with other networked devices.

- Modular Design: The M580 features a modular design, allowing for flexible configurations and easy scalability. Modules can be added or removed based on specific application requirements.

- Redundancy Options: It supports various redundancy configurations for high availability and reliability, including redundant power supplies, CPUs, and communication networks.

- Cybersecurity: Built-in cybersecurity features help protect against unauthorized access and ensure data integrity.

- EcoStruxure™ Ready: The M580 is part of Schneider Electric’s EcoStruxure™ architecture, enabling seamless integration with other EcoStruxure™ products and solutions for enhanced performance and efficiency.

Benefits:

- Increased Efficiency: The high processing power and advanced communication capabilities of the M580 help improve overall system efficiency and performance.

- Scalability: The modular design allows for easy expansion and adaptation to changing automation needs.

- Reliability: Redundancy options and robust construction ensure high system reliability and uptime.

- Ease of Integration: Native Ethernet support and compatibility with Schneider Electric’s EcoStruxure™ architecture facilitate easy integration with existing systems and infrastructure.

- Enhanced Security: Built-in cybersecurity features help protect against threats and ensure safe and secure operation.

Applications:

- Industrial Automation: The M580 is ideal for controlling complex industrial processes in sectors such as manufacturing, oil and gas, water and wastewater, and energy.

- Process Control: It is used in process control applications that require high precision, reliability, and scalability.

- Infrastructure: The M580 is also used in infrastructure projects, including transportation systems, smart grids, and building automation.

Detailed Overview of Modicon M580

1. System Architecture and Design:

- Modular Design: The M580’s modular architecture allows for easy configuration and expansion. Modules include CPU, power supply, communication, and I/O modules, which can be mixed and matched to meet specific application needs.

- Backplane: A high-speed backplane supports fast communication between modules, ensuring efficient data exchange and system performance.

2. CPU and Performance:

- High-Performance CPUs: The M580 offers a range of CPUs with varying levels of performance to handle different application requirements. These CPUs come with advanced processing capabilities, enabling the control of complex processes.

- Memory and Storage: The CPUs are equipped with ample memory and storage options to manage large applications and store significant amounts of data.

3. Communication and Networking:

- Native Ethernet Support: The M580 supports multiple Ethernet ports, allowing for high-speed and reliable communication. It supports various Ethernet protocols, including Modbus TCP/IP and EtherNet/IP.

- Distributed I/O: The system can communicate with distributed I/O modules over Ethernet, reducing wiring complexity and improving system flexibility.

- Redundant Networks: The M580 supports redundant Ethernet networks, ensuring continuous communication even in the event of a network failure.

4. Redundancy and Reliability:

- CPU Redundancy: The M580 offers hot-standby CPU redundancy, where a backup CPU can take over control without interrupting the process in case of a primary CPU failure.

- Power Supply Redundancy: Redundant power supply options ensure continuous operation even if one power supply fails.

- Network Redundancy: Dual Ethernet networks provide communication redundancy, enhancing system reliability.

5. Cybersecurity:

- Security Features: The M580 includes various cybersecurity features such as user authentication, encrypted communication, and firewall capabilities to protect against unauthorized access and cyber threats.

- Compliance: It complies with industry standards and best practices for cybersecurity, ensuring robust protection for critical applications.

6. Programming and Configuration:

- EcoStruxure™ Control Expert: The M580 is programmed and configured using Schneider Electric’s EcoStruxure™ Control Expert (formerly Unity Pro) software, which provides a user-friendly environment for developing control applications.

- Standard Languages: The software supports IEC 61131-3 standard programming languages, including Ladder Logic, Function Block Diagram, Structured Text, and Sequential Function Chart.

7. Integration with EcoStruxure™:

- EcoStruxure™ Ready: The M580 integrates seamlessly with Schneider Electric’s EcoStruxure™ architecture, which provides end-to-end solutions for energy management and automation.

- Analytics and Monitoring: Through EcoStruxure™, the M580 can connect to cloud-based analytics and monitoring tools, enabling predictive maintenance, real-time monitoring, and performance optimization.

8. I/O Modules:

- Wide Range of Modules: The M580 supports a variety of digital and analog I/O modules, including high-density and specialty modules, to meet diverse application requirements.

- Hot-Swappable: Many I/O modules are hot-swappable, allowing for replacement without shutting down the system, minimizing downtime.

9. Applications:

- Manufacturing: Advanced control capabilities for automation in manufacturing processes.

- Process Industries: Reliable control for processes in oil and gas, chemicals, food and beverage, and pharmaceuticals.

- Water and Wastewater: Efficient and reliable operation of water treatment and distribution systems.

- Energy: Control and monitoring of power generation, transmission, and distribution systems.

- Infrastructure: Automation and control for transportation, smart buildings, and other infrastructure projects.

Benefits:

- Increased Efficiency: Enhances operational efficiency through high processing power and advanced communication capabilities.

- Scalability: Easily scalable to adapt to growing or changing automation needs.

- High Availability: Redundancy features ensure high system availability and uptime.

- Ease of Integration: Seamless integration with other systems and devices within the EcoStruxure™ architecture.

- Robust Security: Comprehensive cybersecurity measures protect against threats and ensure secure operation.

Certainly! Let’s delve deeper into some specific areas of the Modicon M580 to provide more detailed information.

1. Advanced CPU Features:

- Processing Power: The CPUs in the M580 series are equipped with multicore processors that deliver high-speed performance and multitasking capabilities, enabling the handling of complex automation tasks.

- Real-Time Performance: The M580 supports real-time operating systems, ensuring precise and deterministic control for time-sensitive applications.

2. Communication Protocols:

- Ethernet/IP: Supports seamless integration with other Ethernet/IP devices and systems, making it suitable for a wide range of industrial automation applications.

- Modbus TCP/IP: Native support for Modbus TCP/IP allows easy communication with a variety of Modbus devices and systems.

- Profinet and Profibus: Optional communication modules can provide support for Profinet and Profibus, expanding the interoperability with other industrial networks.

- DNP3: The M580 supports DNP3 for communication in utilities and energy applications.

3. Programming and Software Tools:

- EcoStruxure™ Control Expert: This software provides a comprehensive suite of tools for programming, configuration, and diagnostics. It includes features such as:

- Graphic Editor: Intuitive drag-and-drop interface for creating control logic.

- Simulation: Offline simulation capabilities to test and validate programs before deployment.

- Diagnostics: Advanced diagnostic tools for troubleshooting and maintaining the control system.

- Libraries and Function Blocks: Extensive libraries of pre-built function blocks and templates speed up development and ensure best practices.

4. Redundancy and High Availability:

- Hot-Standby CPUs: The M580 supports hot-standby configurations where a secondary CPU can instantly take over in case of primary CPU failure without interrupting the process.

- Redundant Power Supplies: Multiple power supply modules ensure continuous operation even if one power source fails.

- Fault Tolerance: The system architecture is designed to be fault-tolerant, minimizing the risk of single points of failure.

5. Cybersecurity Measures:

- Access Control: User authentication and role-based access control restrict unauthorized access to the system.

- Encrypted Communication: Secure protocols ensure that data transmission is encrypted, protecting against eavesdropping and tampering.

- Firewall: Integrated firewall capabilities prevent unauthorized network access and protect against cyber threats.

- Audit Trails: Detailed logging and audit trails help track system changes and user activities for security and compliance purposes.

6. Integration with EcoStruxure™:

- IIoT Connectivity: The M580 can connect to Schneider Electric’s EcoStruxure™ platform, enabling Industrial Internet of Things (IIoT) capabilities such as predictive maintenance and remote monitoring.

- Analytics and Insights: Data collected from the M580 can be analyzed using EcoStruxure™ analytics tools to gain insights into system performance and identify areas for improvement.

- Cloud Services: Secure cloud connectivity allows for remote access, monitoring, and management of the control system from anywhere.

7. Specialized I/O Modules:

- High-Density Digital I/O: Modules that offer a high number of digital input/output channels to maximize space efficiency.

- Analog I/O: Modules that provide high-precision analog inputs and outputs for process control applications.

- Specialty Modules: Includes modules for specific functions such as temperature measurement, vibration monitoring, and motion control.

- Safety I/O: Safety-rated I/O modules for applications that require compliance with safety standards.

8. Case Studies and Applications:

- Manufacturing: The M580 has been used in automotive manufacturing to automate assembly lines, improve quality control, and increase production efficiency.

- Oil and Gas: It is employed in upstream and downstream operations for monitoring and controlling drilling rigs, refineries, and pipelines.

- Water Treatment: Municipal water treatment plants use the M580 for real-time monitoring and control of water purification processes.

- Smart Grids: Utilities use the M580 for managing smart grids, ensuring efficient power distribution, and integrating renewable energy sources.

9. Maintenance and Support:

- Remote Diagnostics: Built-in diagnostics tools and remote access capabilities allow for quick identification and resolution of issues, minimizing downtime.

- Firmware Updates: Schneider Electric provides regular firmware updates to ensure the M580 remains secure and up-to-date with the latest features.

- Technical Support: Comprehensive technical support from Schneider Electric’s experts is available to assist with installation, configuration, and troubleshooting.

10. Future-Proofing:

- Scalable Architecture: The M580 is designed to grow with your needs, making it easy to add new modules and expand system capabilities.

- Compatibility: Backward compatibility with existing Modicon systems ensures a smooth upgrade path and protects your investment.

- Ecosystem Integration: As part of the EcoStruxure™ ecosystem, the M580 will continue to benefit from ongoing developments and innovations in industrial automation technology.

If you need more specific details about a particular aspect of the Modicon M580 or have other questions, please let me know!