Introduction

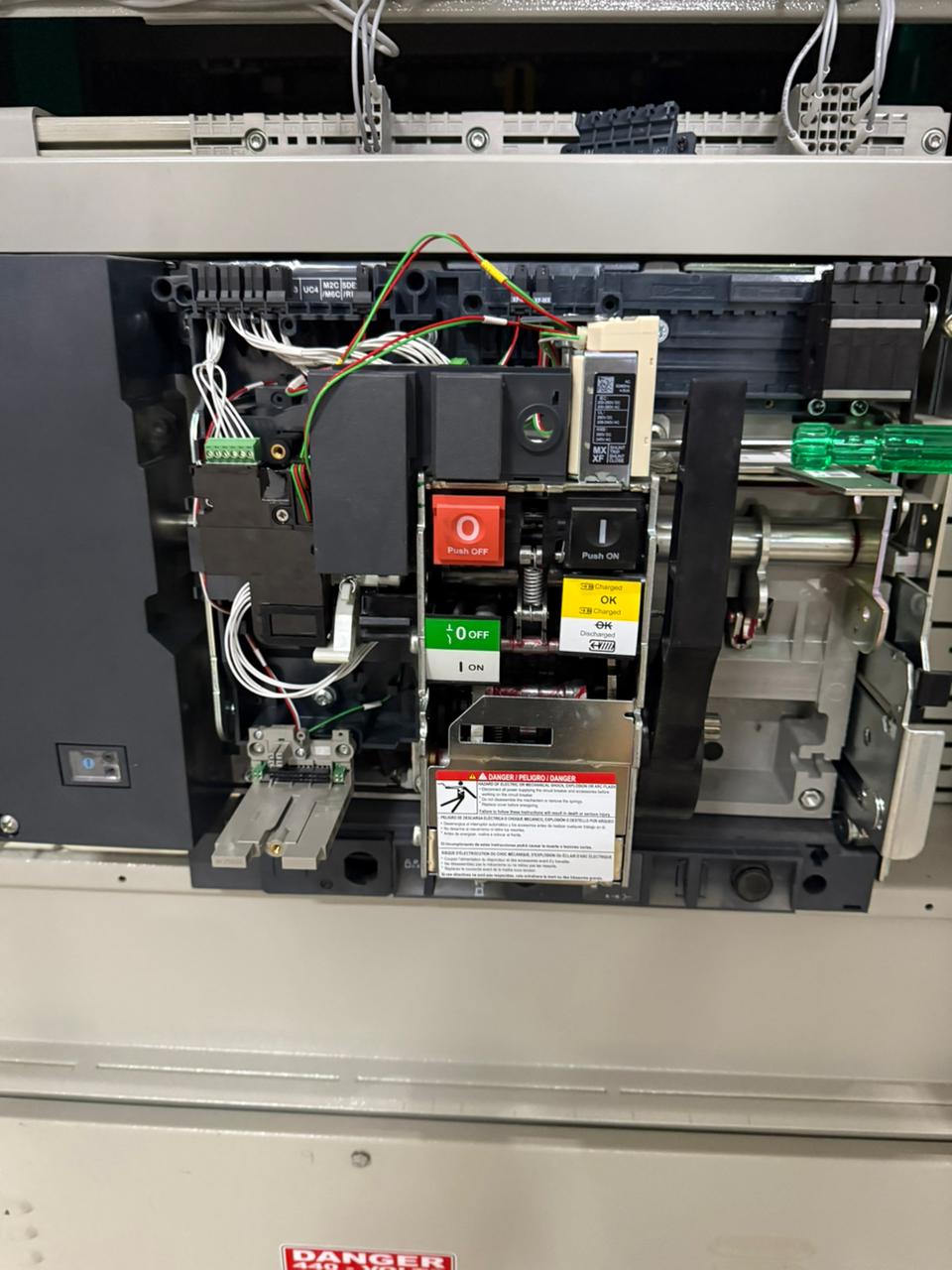

In the era of Industry 4.0, where connectivity and energy intelligence define operational excellence, the role of communication-ready circuit breakers has become indispensable. Schneider Electric, a global leader in energy management and automation, delivers yet another breakthrough solution — the MasterPact™ NW Circuit Breaker Communication Module (MODBUS).

This smart communication module brings the power of data-driven decision-making to traditional electrical systems. It allows the MasterPact NW drawout circuit breaker to communicate via the MODBUS RTU protocol, turning it into a key component of a connected, efficient, and sustainable electrical network.

From industrial plants to commercial complexes, this integration ensures continuous power, remote monitoring, and improved energy visibility — a must-have for modern infrastructure.

What is the MasterPact NW Communication Module?

The MasterPact NW Communication Module is a plug-and-play device designed to connect MasterPact NW air circuit breakers to a MODBUS network. It enables real-time exchange of breaker data — including operating status, measurements, alarms, and fault diagnostics — with supervisory systems like SCADA, BMS (Building Management Systems), and Power Monitoring Expert (PME).

By integrating this module, facility managers gain a complete view of their electrical system’s performance, enabling proactive maintenance and efficient power management.

Key Highlights

- Designed for drawout-type MasterPact NW circuit breakers.

- Supports MODBUS RTU (RS-485) communication protocol.

- Provides real-time monitoring of breaker operation.

- Compatible with EcoStruxure™ Power Monitoring software.

- Offers seamless integration with legacy MasterPact NT/NW and new MasterPact MTZ breakers.

This communication module acts as a digital bridge between traditional power protection and smart, connected energy management.

Why MODBUS? The Global Standard for Industrial Communication

MODBUS RTU is one of the most widely used industrial communication protocols, known for its simplicity, reliability, and interoperability. It allows different devices — from meters to relays and circuit breakers — to communicate over a common bus (RS-485).

Advantages of Using MODBUS for Circuit Breakers

- Universal Compatibility – Works seamlessly with most automation and energy management systems.

- Multi-Device Connectivity – Multiple breakers and devices can share a single network.

- Long-Distance Communication – RS-485 allows communication up to 1200 meters with minimal signal loss.

- Data Transparency – Exchange data such as voltage, current, trip events, and breaker health in real-time.

- Future Scalability – Expand or upgrade easily without major rewiring.

By adopting MODBUS, Schneider’s MasterPact NW ensures standardized and reliable data communication, helping organizations meet the goals of digital transformation.

How the MasterPact NW MODBUS Module Works

The communication module is installed directly on the MasterPact NW circuit breaker and connected to the RS-485 MODBUS network. Once connected, it continuously transmits electrical and operational data to a central monitoring system.

Typical Communication Flow

- Circuit Breaker Installation – The MasterPact NW is mounted in its drawout cradle for easy operation and maintenance.

- Communication Module Setup – The MODBUS communication module is attached to the breaker’s accessory port.

- RS-485 Connection – A twisted pair cable connects the breaker to the MODBUS bus network.

- Parameter Configuration – Each breaker is assigned a unique MODBUS address and communication settings (baud rate, parity, stop bits).

- Data Transmission – The system continuously exchanges data with the monitoring software.

Data Monitored via MODBUS

- Breaker ON/OFF status

- Trip indication and trip cause

- Current and voltage values per phase

- Power and energy parameters

- Alarms and warnings

- Maintenance counters

The result? Complete visibility, traceability, and control of your power distribution system.

Integration with Schneider EcoStruxure™ Platform

The MasterPact NW MODBUS Communication Module is part of Schneider Electric’s EcoStruxure™ Power ecosystem — a powerful IoT-enabled architecture designed for digital power management.

Through EcoStruxure Power Monitoring Expert (PME) or Power Operation (SCADA), users can:

- Visualize real-time breaker status and load data.

- Generate automatic energy and maintenance reports.

- Receive alerts and notifications for abnormal conditions.

- Perform remote control operations (open/close commands).

This smart integration brings efficiency, safety, and sustainability under one digital roof.

Applications of the MasterPact NW MODBUS Module

The versatility and communication capability of the MasterPact NW make it ideal for a wide range of industries and facilities:

1. Data Centers

Power interruptions can cause significant downtime costs. With real-time monitoring via MODBUS, operators can quickly detect overloads, faults, or tripped breakers to restore power efficiently.

2. Commercial Buildings

From hotels to shopping malls, the communication module helps optimize energy usage, maintain uptime, and provide centralized control through a Building Management System (BMS).

3. Industrial Manufacturing

Monitor production line power circuits, identify energy wastage, and enhance preventive maintenance through accurate electrical data and alarms.

4. Hospitals and Healthcare

Ensure uninterrupted supply to critical systems and perform remote diagnostics without physical intervention.

5. Utilities and Energy Infrastructure

Enable smart grid communication for substations and distribution networks with standardized MODBUS connectivity.

MasterPact NW vs. MasterPact MTZ: The Evolution of Smart Circuit Breakers

The MasterPact NW series has long been a benchmark in low-voltage power distribution, offering robustness, reliability, and flexibility. However, Schneider’s innovation didn’t stop there — the MasterPact MTZ builds on this foundation with digital intelligence.

| Feature | MasterPact NW | MasterPact MTZ |

|---|---|---|

| Communication Protocols | MODBUS RTU | MODBUS RTU, Ethernet, IEC 61850 |

| Digital Modules | Optional via Communication Module | Built-in Digital Upgrades |

| Monitoring | Basic data and status | Advanced analytics and waveform capture |

| Integration | PME, SCADA systems | EcoStruxure Power Monitoring |

| Legacy Support | Supported via Modbus Legacy Dataset | Backward compatible with NW series |

With the Modbus Legacy Dataset, both MasterPact NW and MTZ breakers can coexist in the same network, ensuring an easy upgrade path without replacing existing infrastructure998-20826696_GMA.

Installation and Configuration Tips

To achieve reliable communication and stable performance, follow these best practices:

1. Wiring

- Use shielded twisted pair RS-485 cables (minimum 120-ohm impedance).

- Ensure correct A/B polarity across all devices.

- Keep cables away from high-voltage conductors to avoid interference.

- Apply termination resistors (120 Ω) at both ends of the network.

2. Addressing and Parameters

- Assign unique MODBUS addresses for each breaker.

- Recommended baud rate: 9600 or 19200 bps.

- Use 8 data bits, 1 stop bit, even parity (standard MODBUS format).

3. Network Topology

- Connect devices in a daisy-chain (bus) configuration.

- Avoid star or ring topologies to reduce reflections and data errors.

4. Testing

- Verify communication using Schneider Power Monitoring Expert (PME) or any MODBUS-compatible tool.

- Check diagnostic LEDs for data transmission (Tx/Rx).

By following these steps, users can achieve stable and interference-free communication in any industrial or commercial environment.

Advantages of MasterPact NW MODBUS Communication Module

1. Enhanced Safety

Operators can monitor and control breakers remotely, reducing exposure to live panels and electrical hazards.

2. Predictive Maintenance

Trip data, fault history, and load trends help identify potential failures before they cause downtime.

3. Energy Efficiency

Real-time energy data supports informed decisions to reduce consumption and optimize loads.

4. Reduced Downtime

Quick identification of issues means faster troubleshooting and power restoration.

5. Compatibility

Works with both existing MasterPact NT/NW and next-generation MasterPact MTZ systems.

6. Future-Proof Investment

As industries move toward digitization, this communication module ensures your power distribution system remains scalable and upgradable.

Common MODBUS Parameters Available

| Parameter | Description |

|---|---|

| Breaker Status | ON/OFF/Trip condition |

| Trip Cause | Overcurrent, short circuit, earth fault |

| Load Current | Phase-wise current measurement |

| Voltage | Phase and line voltage |

| Power Factor | Real-time PF value |

| Active/Reactive Energy | Consumption statistics |

| Maintenance Counter | Operation and trip count |

| Alarm Status | Fault, warning, and diagnostic codes |

These parameters enable comprehensive electrical analytics, leading to better power reliability and operational transparency.

Example Use Case: Smart Power Monitoring in a Manufacturing Plant

Imagine a manufacturing unit with multiple feeders and machines protected by MasterPact NW breakers. Traditionally, operators needed to manually inspect each breaker for trip events or faults.

By integrating the MODBUS communication module:

- All breakers connect to a central SCADA system.

- Real-time status and load data are visible on a dashboard.

- Automatic alarms are triggered during faults.

- Maintenance teams receive detailed trip causes instantly.

Result? Faster response, improved uptime, and significant cost savings in maintenance and energy efficiency.

Sustainability and Digital Future

The MasterPact NW communication module contributes to sustainable and digital energy management by enabling:

- Lower carbon footprint through optimized energy use.

- Smarter grid connectivity for renewable integration.

- Remote diagnostics, reducing the need for on-site intervention.

Together with Schneider’s EcoStruxure architecture, this module empowers industries to achieve Net Zero and ESG goals while maintaining system reliability.

How to Order and Activate

Ordering and activating Schneider Electric’s digital modules is simple:

- Visit the GoDigital Store on Schneider Electric’s website.

- Enter your breaker serial number to check compatibility.

- Select and purchase the MODBUS Communication Module.

- Install the module following the provided guide.

- Configure the MODBUS parameters and connect to your monitoring system.

💡 Tip: You can contact your local Schneider Electric representative or distributor for installation support and configuration assistance.

Conclusion

The MasterPact NW Communication Module (MODBUS) transforms traditional circuit breakers into smart, connected power devices. It bridges the gap between reliable protection and intelligent energy management.

With features like real-time data sharing, remote monitoring, and predictive maintenance, this solution helps industries enhance safety, reduce downtime, and optimize energy use — the true essence of a connected power system.

Whether you’re managing a high-rise building, an industrial plant, or a data center, integrating MODBUS with MasterPact NW is your first step toward a smart, sustainable, and future-ready electrical infrastructure.

Empower your power system with intelligence — Connect, Communicate, and Control with Schneider Electric MasterPact NW.