Meta Description:

Discover Schneider Heat Tag – the innovative IoT-based early fire detection system designed for electrical panels. Ensure safety with AI-powered heat sensing and predictive alerts.

🌟 Introduction: The Future of Fire Prevention

In today’s connected world, electrical safety has become more critical than ever. Businesses, industries, and smart facilities depend on complex electrical panels that power their operations. But hidden inside those panels lies one of the biggest risks—overheating and electrical fires.

That’s where Schneider Heat Tag steps in.

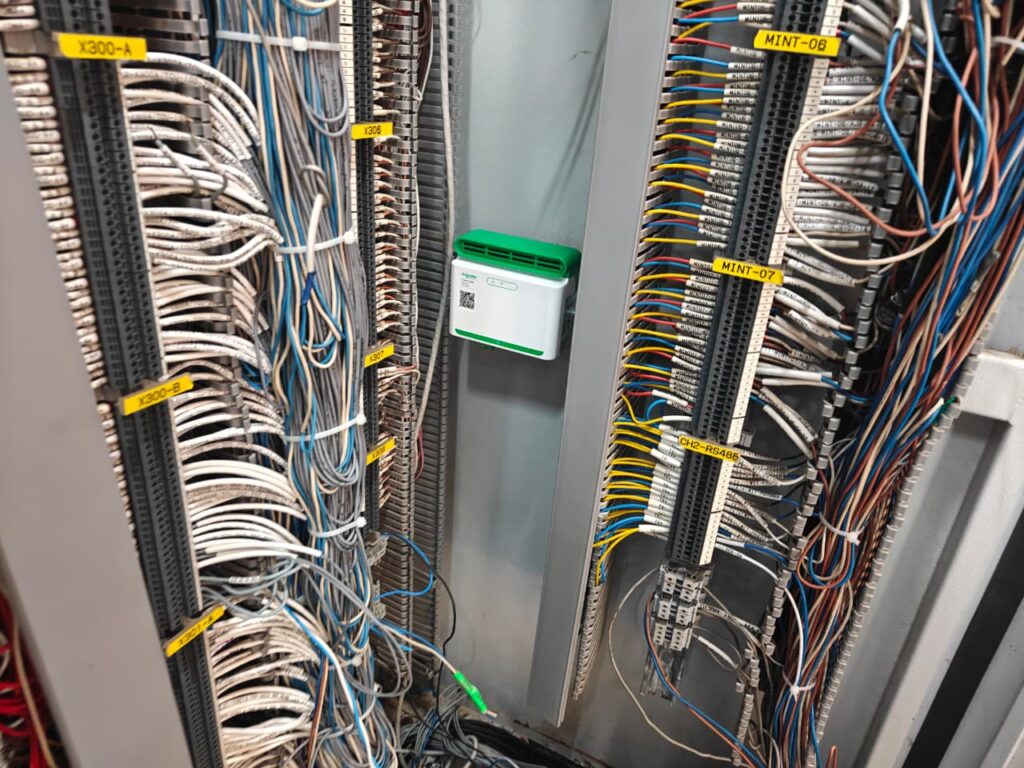

Developed by Schneider Electric, the global leader in energy management and automation, Heat Tag is a smart fire prevention device designed to detect overheating cables and electrical faults before smoke or fire ever occurs.

This innovative IoT sensor is transforming how companies approach safety, reliability, and maintenance—making buildings and industries safer, smarter, and more sustainable.

⚙️ What is Schneider Heat Tag?

Schneider Heat Tag is an IoT-based predictive fire prevention sensor that continuously monitors air particles inside electrical enclosures to detect early signs of overheating or insulation faults.

Unlike traditional smoke detectors that only react after a fire starts, Heat Tag predicts and prevents potential fire hazards.

It works by analyzing invisible gases and particles released by overheating cables or electrical components, sending early alerts to operators before the situation becomes dangerous.

In short:

🔸 Traditional detectors = react after fire

🔸 Schneider Heat Tag = acts before fire

💡 How Schneider Heat Tag Works

The Heat Tag system uses AI-powered sensors and air analysis technology to continuously monitor the atmosphere inside electrical cabinets.

Here’s a simple breakdown of its working principle:

- Continuous Air Sampling:

The sensor draws air samples from the electrical enclosure. - Gas Analysis:

It detects the presence of gases and volatile organic compounds (VOCs) typically released when cables or connections overheat. - AI Algorithm Detection:

Schneider’s proprietary algorithm evaluates the composition and concentration of these gases. - Predictive Alerting:

When abnormal heat signatures are detected, the device sends an early alert via EcoStruxure, Building Management Systems (BMS), or SCADA. - Maintenance Action:

The maintenance team receives actionable information to intervene before any damage or fire occurs.

🔍 Key Features of Schneider Heat Tag

| Feature | Description |

|---|---|

| Predictive Fire Detection | Detects overheating and insulation faults before visible smoke appears. |

| IoT Connectivity | Seamless integration with Schneider EcoStruxure and Modbus communication. |

| Compact & Easy to Install | Fits easily inside electrical cabinets without major modifications. |

| AI-Powered Analysis | Smart algorithms distinguish between harmless heating and actual risk. |

| Low Maintenance | Requires no calibration or consumables. |

| Wireless & Scalable | Can be networked across multiple panels in industrial sites. |

🏭 Applications of Schneider Heat Tag

Schneider Heat Tag is suitable for a wide range of industrial, commercial, and critical infrastructure environments:

- Data centers – Prevent electrical fires in power distribution units.

- Manufacturing plants – Protect machinery control panels.

- Commercial buildings – Enhance electrical safety in distribution boards.

- Hospitals & laboratories – Maintain uninterrupted power safety.

- Renewable energy facilities – Monitor solar inverter panels and junction boxes.

⚡ Why Early Heat Detection Matters

Electrical faults are one of the leading causes of industrial fires worldwide.

According to global statistics, over 30% of industrial fires start due to electrical failures or overheating. Traditional fire detectors react only after smoke or flame develops—by that time, damage is often inevitable.

Schneider Heat Tag changes this paradigm by giving you:

- Extra response time: Minutes or hours to act before fire spreads.

- Operational continuity: Avoid production losses and downtime.

- Safety assurance: Protect people, assets, and infrastructure.

- Regulatory compliance: Meet modern fire safety and ESG standards.

🌐 Integration with Schneider EcoStruxure

Heat Tag is fully compatible with Schneider’s EcoStruxure platform—a leading IoT-enabled architecture that connects devices, edge control, and analytics.

🔗 Integration Benefits:

- Real-time data visualization

- Predictive maintenance notifications

- Remote monitoring from smartphones or dashboards

- Connection with SCADA, BMS, or PME systems

When combined with Schneider circuit breakers, Smart Panels, and power monitoring systems, Heat Tag creates a complete safety ecosystem that enhances both performance and reliability.

🧠 AI and Predictive Maintenance

The use of artificial intelligence (AI) in Heat Tag enables it to learn from historical data and improve accuracy over time.

This predictive approach allows facilities to:

- Detect unusual temperature patterns early.

- Schedule maintenance before a fault develops.

- Reduce false alarms common in conventional systems.

It’s not just fire prevention—it’s smart asset protection.

🌿 Sustainability and Cost Efficiency

By preventing electrical fires and avoiding equipment damage, Heat Tag contributes directly to sustainability goals.

- Reduced carbon footprint: Prevents fire-related emissions.

- Extended asset life: Keeps panels and wiring in good condition.

- Lower insurance costs: Demonstrates proactive fire risk management.

With no consumables or frequent replacements, it’s also a cost-effective long-term investment.

🔧 Installation and Setup

The installation of Schneider Heat Tag is straightforward:

- Mount the Heat Tag sensor inside or near the electrical panel.

- Connect via Modbus or wireless communication.

- Integrate with the monitoring system (EcoStruxure / BMS).

- Configure alarm thresholds and alerts.

No recalibration or filters are needed, making it a plug-and-protect solution for any site.

🆚 Schneider Heat Tag vs. Traditional Fire Detection

| Aspect | Traditional Detector | Schneider Heat Tag |

|---|---|---|

| Detection Time | After smoke/fire | Before smoke/fire |

| Detection Type | Visible smoke/heat | Invisible gases & overheating signs |

| Maintenance | Requires testing | Maintenance-free |

| Response Time | Reactive | Predictive |

| Integration | Standalone | IoT & EcoStruxure integrated |

💬 Frequently Asked Questions (FAQs)

1. What is the main purpose of Schneider Heat Tag?

To detect early overheating and prevent electrical fires before smoke or flame occurs.

2. Can Heat Tag be used in existing electrical panels?

Yes. It’s compact and designed for easy retrofit in existing installations.

3. Does it require maintenance or calibration?

No. Heat Tag is maintenance-free and automatically self-calibrates.

4. How is it connected to monitoring systems?

Through Modbus, wireless, or directly via Schneider’s EcoStruxure software.

5. What industries benefit most from Heat Tag?

Data centers, manufacturing plants, commercial facilities, and renewable energy sites.

🏁 Conclusion: A Smarter Way to Prevent Fires

The Schneider Heat Tag represents a major leap forward in electrical fire prevention technology. By detecting overheating long before a fire begins, it gives facilities the power to act early, save lives, protect assets, and maintain uninterrupted operations.

With its AI-based sensing, IoT connectivity, and seamless EcoStruxure integration, Heat Tag is not just a safety device—it’s a cornerstone of predictive maintenance and sustainable industrial safety in 2025 and beyond.

If you’re serious about electrical safety, reliability, and efficiency, the Schneider Heat Tag deserves a place in your system.