Introduction:

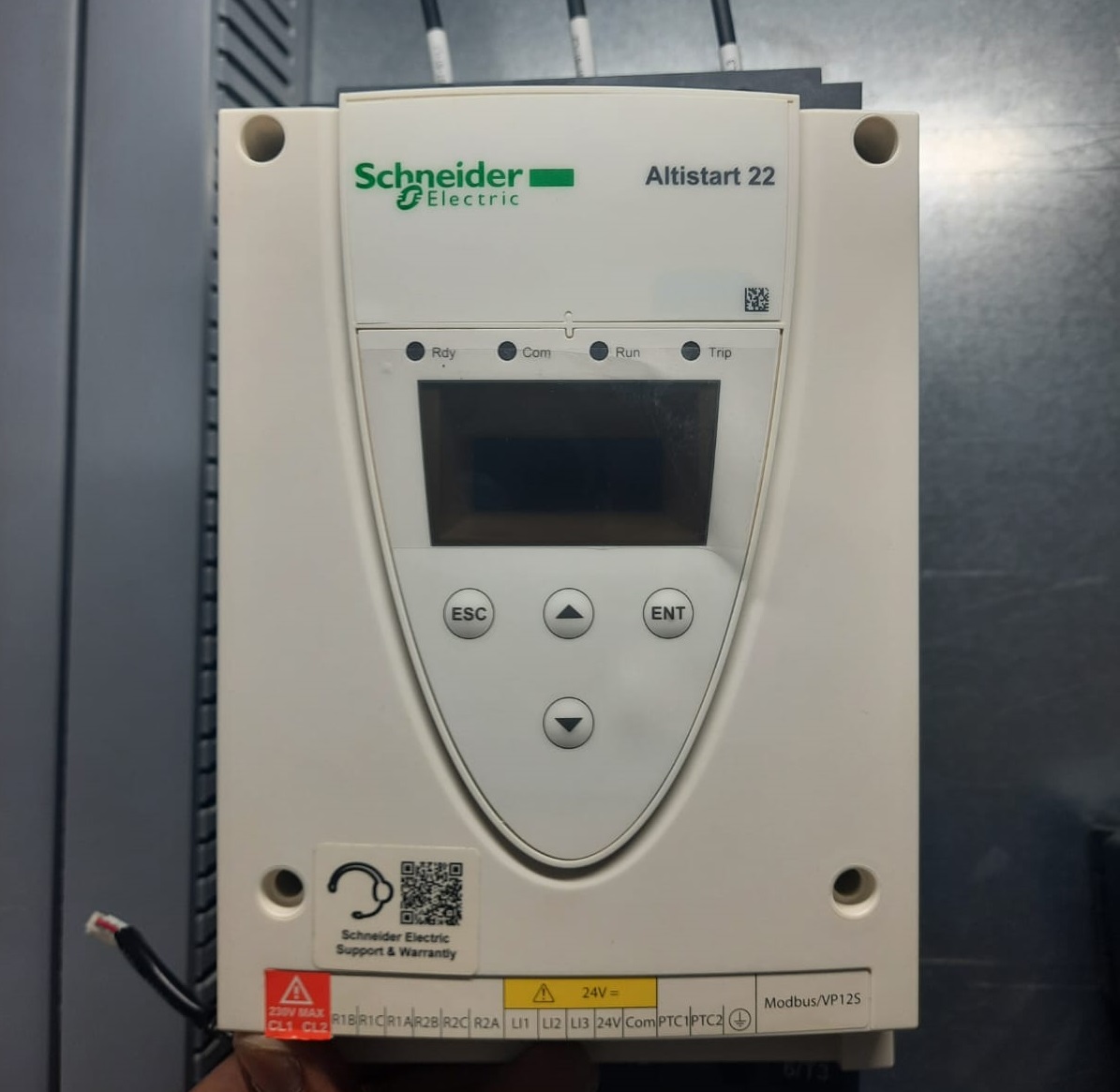

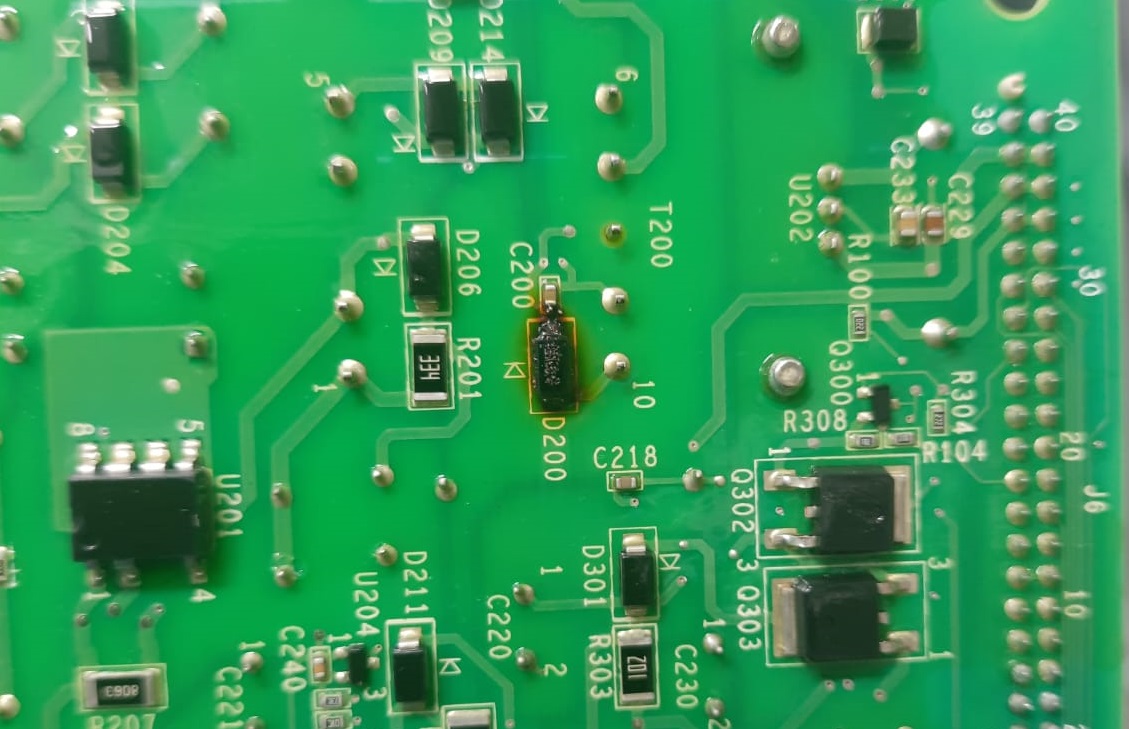

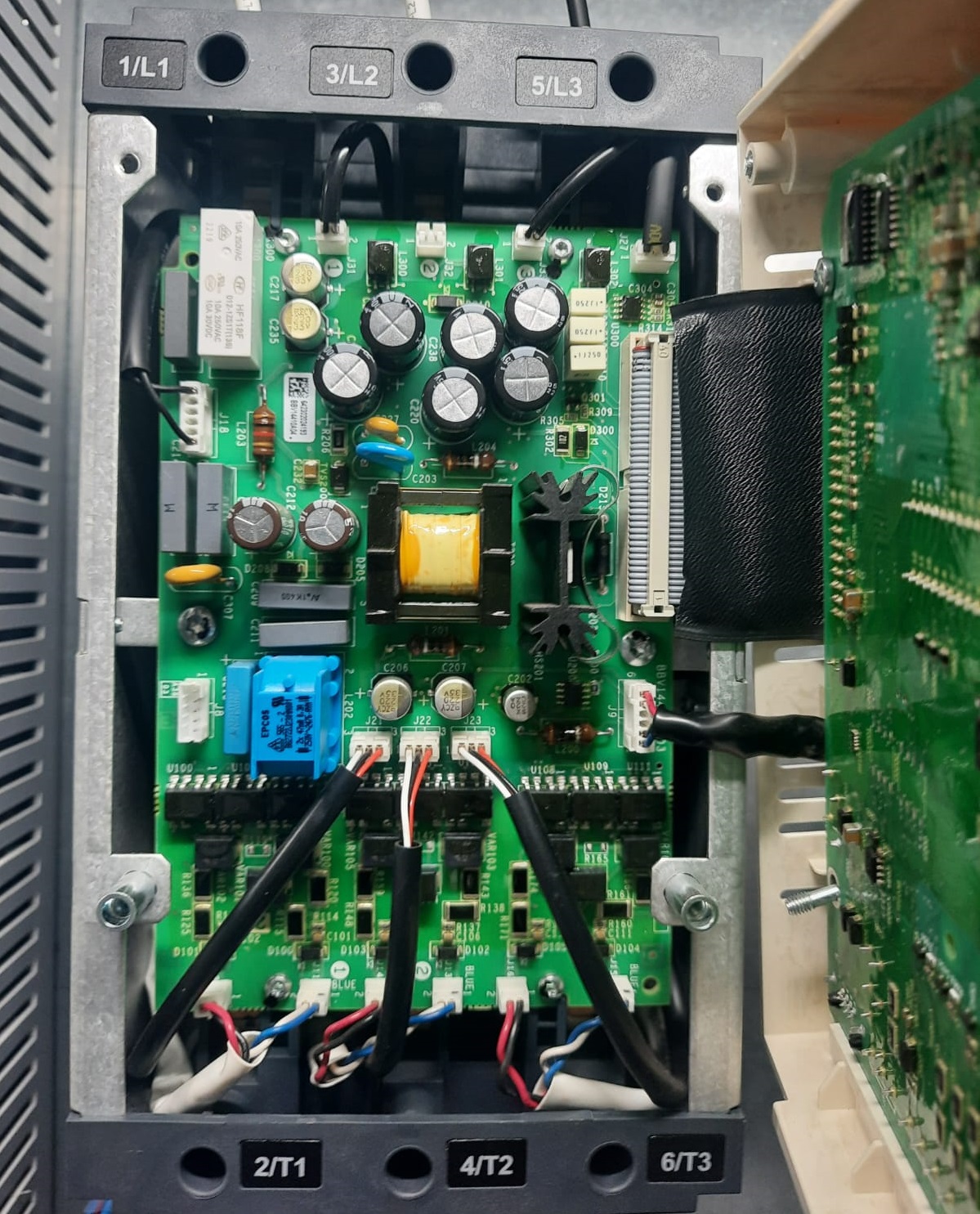

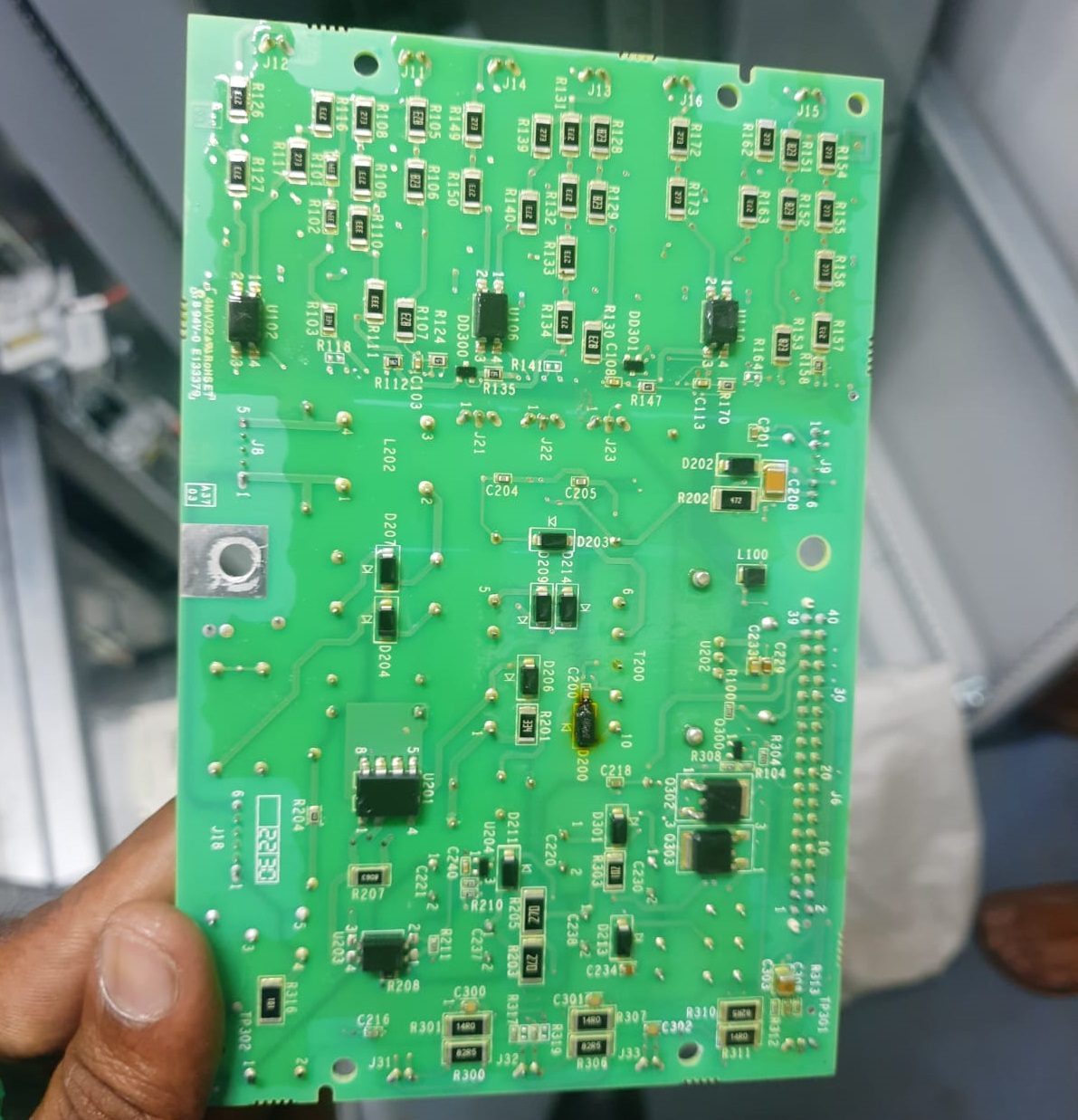

Welcome to this article, where we delve into the topic of diode burning on an Altistart 22 PCB. The Altistart 22, developed by Schneider Electric, is a crucial motor starter used in various applications. However, it is not immune to issues such as diode burning, which can hinder its performance and reliability.

In this article, we will explore the different reasons why diode burning can occur on an Altistart 22 PCB. Understanding these causes is essential for troubleshooting and implementing preventive measures to ensure the smooth operation of the motor starter.

By gaining insights into the potential culprits behind diode burning, you will be equipped with the knowledge necessary to identify and address these issues effectively. So, let’s dive into the various factors that can lead to diode burning on the Altistart 22 PCB and learn how to mitigate these risks for optimal performance and longevity.

Overvoltage

Overvoltage refers to a situation where the voltage supplied to a diode on an Altistart 22 PCB exceeds its maximum rating. This can result in the diode burning out and malfunctioning. Overvoltage can occur due to various factors, including sudden power surges, electrical system faults, or improper voltage regulation.

When the voltage surpasses the diode’s maximum rating, it causes excessive heat generation. The diode is not designed to handle such high levels of voltage, leading to thermal stress and ultimately its failure. This burning can have detrimental effects on the functionality of the Altistart 22 motor starter.

To prevent overvoltage issues, it is essential to ensure a stable power supply. Proper voltage regulation mechanisms such as voltage regulators, surge protectors, or power conditioning devices should be employed. These devices help maintain a consistent voltage level and protect the diodes from voltage spikes or fluctuations.

Regular inspections of the electrical system and Altistart 22 PCB can also help identify any potential overvoltage risks. Monitoring the voltage levels and taking prompt action to rectify any abnormalities or faults can significantly reduce the chances of diode burning.

By effectively managing overvoltage situations, the lifespan and performance of the Altistart 22 motor starter can be preserved, ensuring the smooth operation of the connected motors and preventing costly damages or downtime.

Overcurrent

Overcurrent is another factor that can lead to the burning of a diode on an Altistart 22 PCB. It occurs when the current flowing through the diode exceeds its maximum rated value, causing excessive heat dissipation and ultimately resulting in diode failure.

There are several possible reasons for overcurrent situations. One common cause is a short circuit in the connected equipment or within the motor starter system. A short circuit creates a low-resistance path, allowing a significantly higher current to flow through the diode than it can handle. This excessive current causes the diode to heat up rapidly, leading to burning and malfunctioning.

To protect against overcurrent, it is important to implement proper circuit protection mechanisms. This can include using fuses, circuit breakers, or current-limiting resistors in the electrical system. These devices help limit the current flowing through the diode, preventing it from reaching destructive levels and ensuring its safe operation.

Regular maintenance and inspections of the Altistart 22 PCB can also help identify any potential overcurrent issues. Monitoring the current levels and promptly addressing any abnormalities or faults in the system can significantly reduce the risk of diode burning.

By effectively managing overcurrent situations, the Altistart 22 motor starter can operate within its specified limits, minimizing the chances of diode failure and ensuring reliable motor control and protection.

Reverse Polarity

Reverse polarity is a significant cause of diode burning on an Altistart 22 PCB. Diodes are designed to allow current flow in one direction while blocking it in the opposite direction. When a diode is connected with reverse polarity, meaning the positive and negative terminals are swapped, it can lead to detrimental consequences.

When reverse polarity occurs, the diode becomes effectively “reverse biased,” causing an excessive current to flow through it in the wrong direction. This abnormal current flow generates excessive heat, which can rapidly damage the diode and result in burning or failure.

To prevent reverse polarity issues, it is crucial to exercise caution during installation or replacement of diodes on the Altistart 22 PCB. Double-checking the polarity and ensuring correct connections are made is essential. Reviewing the diode datasheet or manufacturer’s guidelines can provide clear indications of the correct polarity and pin configuration.

Furthermore, utilizing proper marking and labeling of terminals can help prevent inadvertent reverse polarity connections. Employing color-coding or clear identification of positive and negative terminals can significantly reduce the risk of reversing the polarity.

Regular inspections and verification of the diode connections can also contribute to detecting and rectifying any reverse polarity issues promptly.

By taking precautions to ensure correct polarity connections, the risk of diode burning on the Altistart 22 PCB can be minimized, ensuring the proper functioning and reliability of the motor starter system.

Component Failure

Component failure is a potential cause of diode burning on an Altistart 22 PCB. While diodes are typically reliable components, they can occasionally experience internal defects or manufacturing issues that can lead to their failure and subsequent burning.

There are several factors that can contribute to component failure:

- Poor quality control: In some cases, diodes may suffer from manufacturing defects or poor quality control during the production process. These defects can weaken the diode’s internal structure or compromise its ability to handle the intended current and voltage levels, ultimately leading to failure.

- Temperature stress: Diodes are sensitive to temperature variations. Excessive heat or temperature fluctuations can degrade their performance over time. If the Altistart 22 PCB operates in an environment with high temperatures or inadequate heat dissipation, it can accelerate component aging and increase the risk of diode failure.

- Mechanical damage: Physical stress or mishandling during installation, maintenance, or transportation can cause mechanical damage to the diode. Cracks, fractures, or other physical impairments can compromise the diode’s functionality and make it more susceptible to burning.

- Aging: Like all electronic components, diodes have a limited lifespan. Over time, the materials and connections within the diode can degrade, leading to decreased performance and eventually failure. This aging process can be influenced by factors such as operating conditions, electrical stresses, and the quality of the diode itself.

Regular inspections, preventive maintenance, and adherence to proper handling procedures can help identify potential component failures before they occur. Using high-quality diodes from reputable manufacturers can also reduce the likelihood of premature failures and burning on the Altistart 22 PCB.

By being aware of the potential for component failure and taking appropriate measures to address it, the reliability and longevity of the Altistart 22 motor starter can be safeguarded, ensuring smooth operation and minimizing unexpected downtime.

Environmental Factors

Environmental factors can have a significant impact on the burning of a diode on an Altistart 22 PCB. The operating environment in which the motor starter is installed can influence the performance and lifespan of electronic components, including diodes.

Here are some environmental factors to consider:

- Temperature: Extreme temperatures, whether excessively hot or cold, can affect the functionality of diodes. High temperatures can accelerate the aging process, degrade the diode’s performance, and increase the likelihood of burning. Conversely, very low temperatures can make the diode more brittle and susceptible to damage. Maintaining suitable temperature conditions within the Altistart 22’s operating environment is crucial to prevent diode failures.

- Humidity: High humidity levels can cause moisture to accumulate on the Altistart 22 PCB, leading to corrosion and short circuits. Moisture can also affect the insulation properties of the PCB, increasing the risk of electrical faults and diode burning. Implementing measures such as moisture barriers, proper ventilation, or humidity control can help mitigate these risks.

- Contaminants: Dust, dirt, and other contaminants can accumulate on the Altistart 22 PCB over time. These contaminants can obstruct airflow, impair heat dissipation, and increase the likelihood of electrical short circuits. Regular cleaning and maintenance of the PCB, along with keeping the surrounding area clean, can minimize the impact of contaminants on diode performance.

- Chemicals and Gases: Exposure to corrosive chemicals or gases in the environment can degrade the materials and connections within diodes. This degradation can lead to decreased performance and eventual burning. If the Altistart 22 is installed in an environment with such substances, appropriate protective measures should be implemented, such as enclosures or filters, to shield the PCB from their effects.

By providing a suitable operating environment for the Altistart 22, including temperature and humidity regulation, minimizing exposure to contaminants, and protecting against corrosive substances, the risk of diode burning can be significantly reduced. Regular inspections and maintenance should be conducted to ensure any environmental risks are addressed promptly, ensuring the long-term functionality and reliability of the motor starter.