The industrial automation landscape is undergoing a profound transformation, driven by the convergence of information technology (IT) and operational technology (OT). At the forefront of this revolution stands Schneider Electric’s EcoStruxure Automation Expert, the world’s first software-centric industrial automation system that fundamentally reimagines how industrial operations are designed, deployed, and maintained. This groundbreaking platform represents a paradigm shift from traditional hardware-dependent automation systems to a flexible, software-defined approach that delivers unprecedented performance improvements, cost savings, and operational agility.se+2

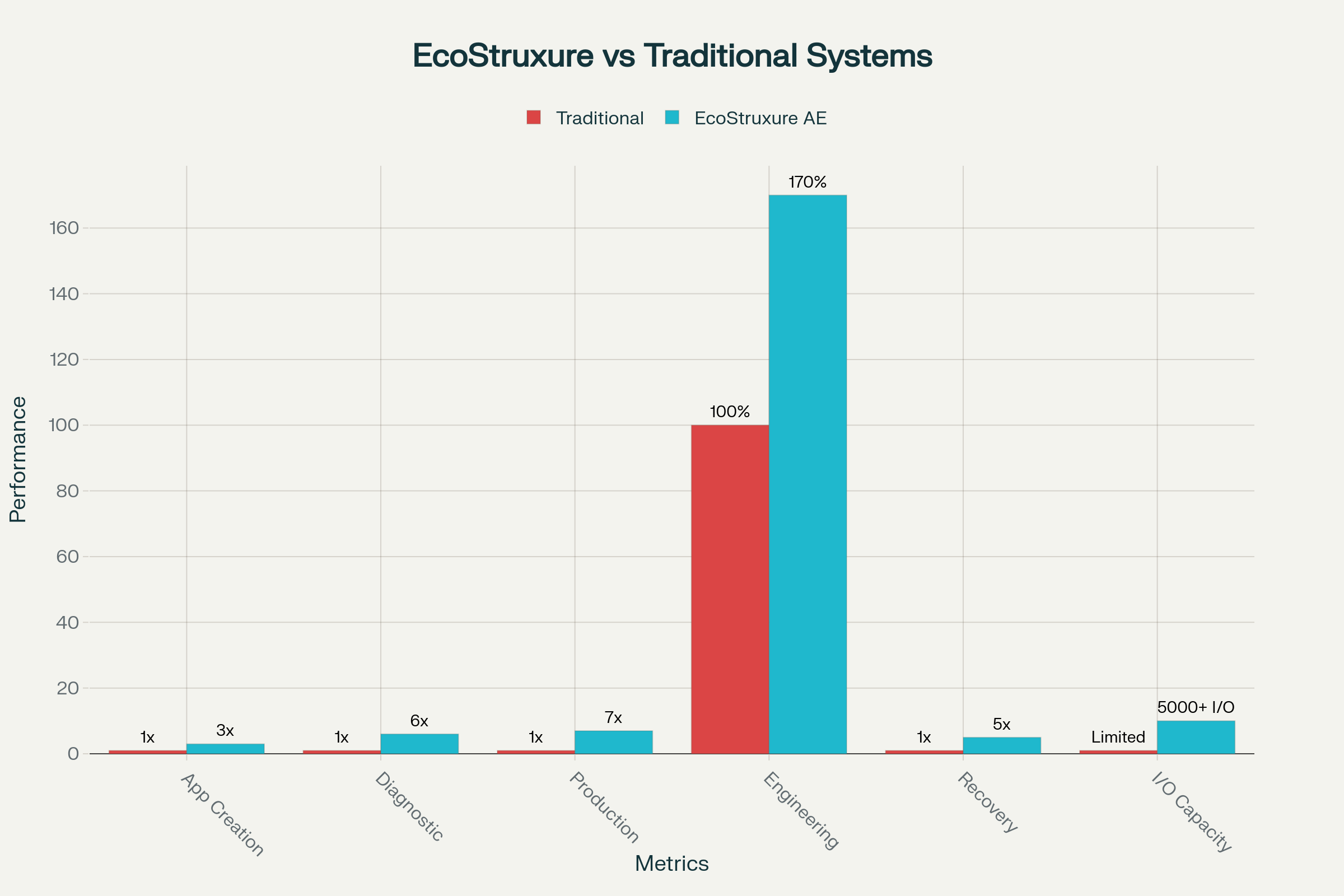

EcoStruxure Automation Expert has already demonstrated remarkable success across over 530 active projects globally, delivering up to 3x faster application creation, 6x faster diagnostics, and 7x faster production alterations compared to traditional automation systems. These performance gains translate into tangible business value, with organizations achieving up to 70% improved engineering efficiency and 80% reduction in recovery time after system faults. The platform’s revolutionary approach enables companies to break free from the constraints of proprietary, closed automation systems while embracing the flexibility and innovation potential of universal automation.engineering-update+3

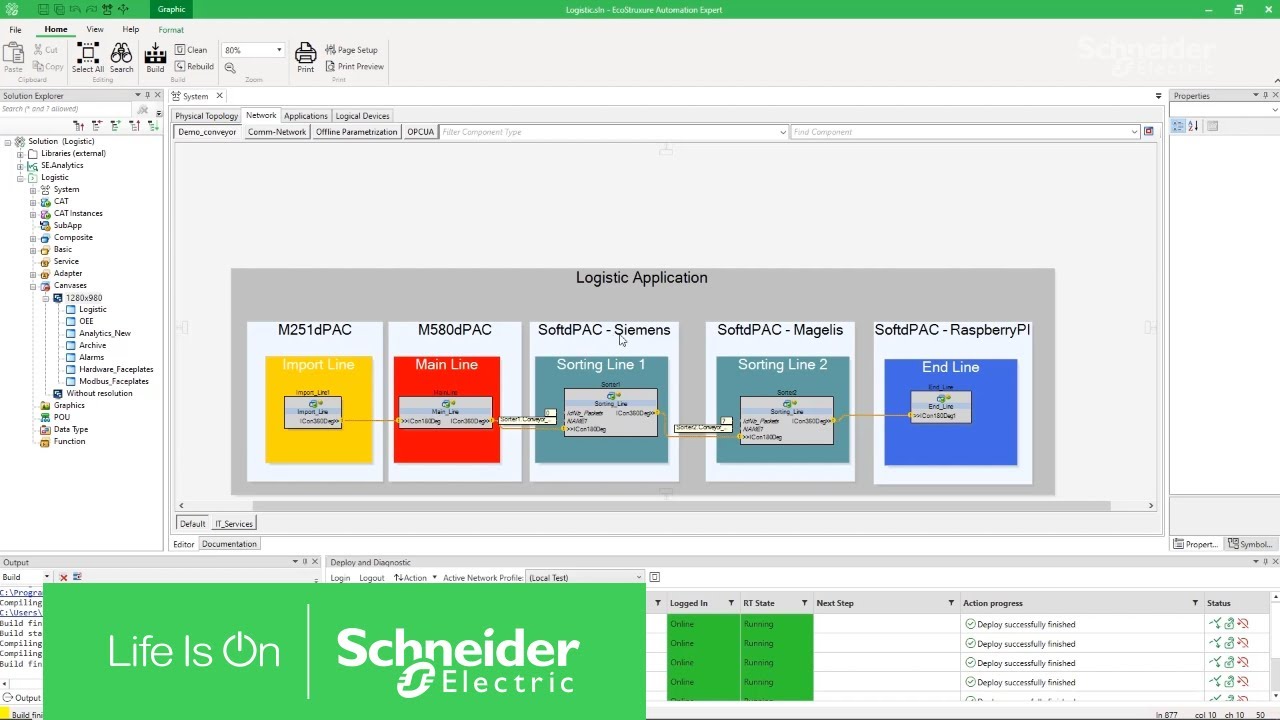

Interface of Schneider Electric’s EcoStruxure Automation Expert showing a logistic application network with connected automation modules and deployment status indicating successful operation youtube

The Revolutionary Architecture of Software-Defined Automation

Breaking Free from Hardware Dependencies

Traditional industrial automation systems have long suffered from the fundamental limitation of tightly coupling software applications to specific hardware platforms. This approach creates vendor lock-in situations, limits flexibility, and drives up both capital and operational expenses. EcoStruxure Automation Expert addresses these challenges through its software-centric architecture that completely decouples applications from the underlying hardware infrastructure.se+2

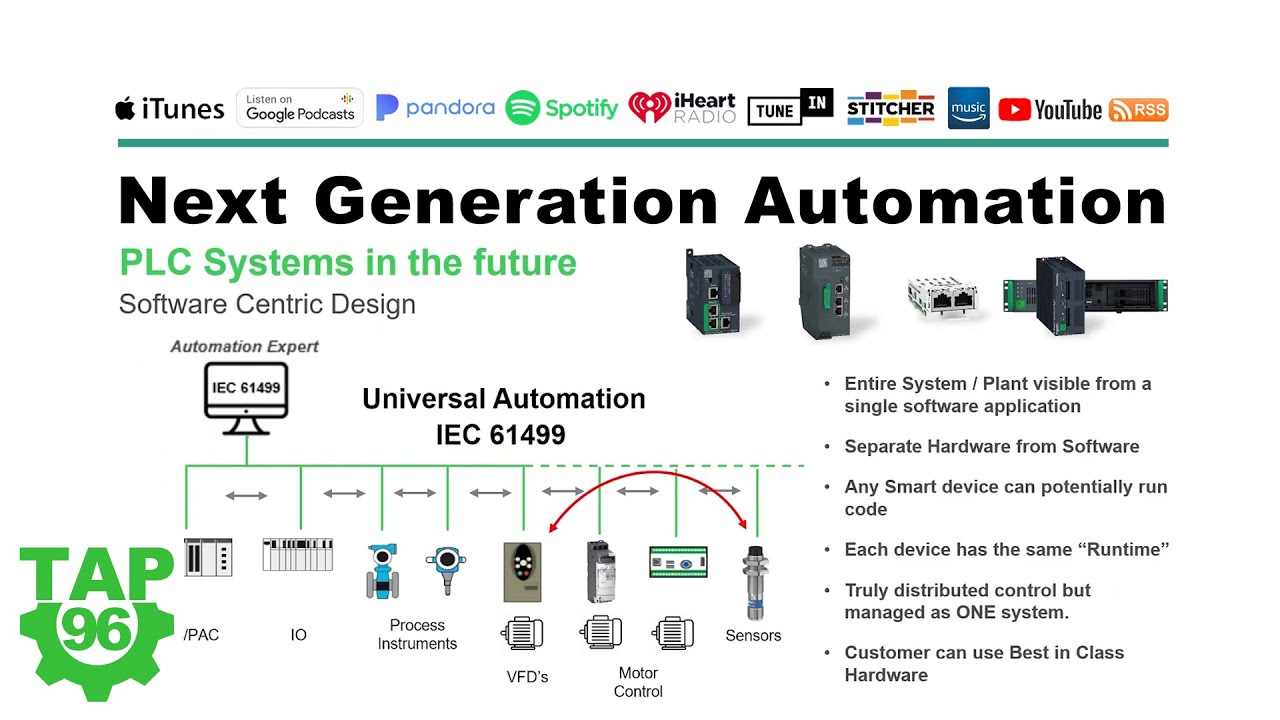

The platform leverages the IEC 61499 standard for distributed control systems, extending the capabilities of the existing IEC 61131 standard to enable truly portable and interoperable automation applications. This standards-based approach allows engineers to develop automation applications using asset-centric, portable, proven-in-use software components that can run on any compatible hardware platform, regardless of vendor.pandct+3

This architectural shift delivers immediate practical benefits. Organizations can now keep their existing industrial hardware while updating to the latest plant automation software, eliminating the need for costly hardware overhauls during system upgrades. The platform’s hardware-independent design enables seamless integration of best-in-class components from multiple vendors, creating a truly open ecosystem for industrial automation.se+3

The Universal Automation Vision

Schneider Electric’s vision for universal automation represents a fundamental reimagining of industrial control systems. Universal automation creates an ecosystem of plug-and-produce automation software components that solve specific customer problems through standardized, interoperable solutions. This approach mirrors the success of open platforms in the information technology sector, where applications developed for one platform can seamlessly run across different hardware vendors.news.bpx+2

The benefits of universal automation extend far beyond technical capabilities. By adopting standardized automation layers common across vendors, industrial enterprises gain access to limitless opportunities for growth and modernization. The approach addresses the critical challenge engineers face with closed, proprietary automation platforms that restrict the adoption of best-of-breed technologies and limit innovation potential.se+1

Next generation software-centric automation system using IEC 61499 standard showcasing Schneider Electric hardware and unified system control features youtube

Advanced Features and Capabilities

Version 24 Enhancements and Scalability

The latest EcoStruxure Automation Expert v24 introduces significant enhancements that expand the platform’s capabilities for larger industrial installations. The updated version features an impressive 5,000 I/O capacity per solution, enabling support for larger plant architectures and more complex automation scenarios. This substantial increase in I/O capacity allows organizations to deploy comprehensive automation solutions across extensive industrial facilities without system limitations.engineering-update+1

Communication protocol support has been significantly expanded in version 24, building upon the platform’s existing support for Ethernet/IP, Modbus TCP, and HART protocols. The new version integrates MQTT, OPC-UA, and Profinet communication protocols, providing enhanced connectivity options for diverse industrial environments. These additional protocols ensure seamless integration with existing industrial infrastructure while supporting modern Industrial Internet of Things (IIoT) implementations.pandct+1

The platform now includes advanced artificial intelligence (AI) functions that help engineers develop sophisticated features such as visual inspections and predictive maintenance capabilities. This AI integration represents a significant step forward in enabling autonomous operations and intelligent decision-making within industrial control systems.

Single-Line Engineering and Flexible Deployment

One of EcoStruxure Automation Expert’s most innovative features is its single-line engineering approach that dramatically simplifies system configuration and deployment. The platform automatically adapts and establishes communication between controllers, assets, and visualization devices, eliminating the manual configuration work typically required in traditional automation systems.

The system enables bi-directional data flow and recognizes connected objects while preventing false connections, ensuring robust and reliable system operation. This intelligent connectivity reduces engineering time and minimizes the risk of configuration errors that can lead to system failures or safety issues.se+1

Engineers can design and distribute applications to either physical or virtual controllers, providing unprecedented flexibility in system architecture deployment. The platform supports distributed, centralized, or hybrid architectures with minimal additional programming, allowing organizations to optimize their automation infrastructure based on specific operational requirements rather than hardware limitations.se

Enhanced Cybersecurity and System Reliability

Modern industrial automation systems face increasing cybersecurity threats, making robust security features essential for operational continuity. EcoStruxure Automation Expert v24 incorporates enhanced cybersecurity capabilities that protect industrial operations while enabling secure connectivity to enterprise systems. The platform provides encrypted communications and works seamlessly with third-party software while maintaining hardware-agnostic flexibility.

The system’s architecture inherently improves reliability through its distributed approach to control logic. Unlike traditional systems, where control functions are concentrated in single controllers, EcoStruxure Automation Expert enables flexible distribution of control logic across multiple devices on the network. This approach allows organizations to move control functions to spare devices during maintenance operations, maintaining process continuity while performing system updates or repairs.

Performance comparison: EcoStruxure Automation Expert vs Traditional Automation Systems

Industry Applications and Real-World Success Stories

Diverse Industry Implementations

EcoStruxure Automation Expert has proven its versatility across multiple industrial sectors, with successful deployments spanning energy and chemicals, life sciences, water and wastewater treatment, food and beverage manufacturing, logistics operations, and mineral, metals, and mining industries. Each industry benefits from the platform’s flexible architecture while addressing sector-specific challenges and regulatory requirements.

In the water and wastewater sector, the platform enables complete lifecycle management, integration of IT/OT services, and improved system diagnostics for automation systems. The solution facilitates close integration with the AVEVA portfolio, extending capabilities and providing options to add or modify systems as future needs arise. This flexibility is particularly valuable in municipal water treatment facilities where regulatory requirements and capacity demands frequently change.

The energy sector benefits significantly from EcoStruxure Automation Expert’s ability to integrate new energy solutions without overhauling entire automation systems. Renewable energy businesses can simplify the management and maintenance of complex assets while extending their operational lifecycle, supporting sustainability objectives and reducing long-term operational costs.

Case Study: Brilliant Planet’s Algae-Based Carbon Capture

Brilliant Planet, a pioneer in low-cost algae-based carbon capture technology, selected EcoStruxure Automation Expert to support their innovative approach to combating climate change through permanent carbon sequestration. The company required a solution that could modularize their application, enabling them to easily replicate and scale operations across multiple sites.

The implementation linked EcoStruxure Automation Expert with an AVEVA System Platform to control algae cultivation processes utilizing high-frequency satellite data. This integration enabled Brilliant Planet to effectively manage and increase yield through automated closed-loop control while providing the foundation for further expansion. The modular approach allowed the company to copy, paste, and scale their automation solution at each new site, dramatically reducing deployment time and engineering costs.pandct

Case Study: Synesis and Industry 4.0 Development

Synesis, which specializes in facilitating Industry 4.0 software development for small and medium-sized companies, partnered with Schneider Electric to leverage the IEC 61499 compliant EcoStruxure Automation Expert platform. The collaboration focused on developing a complete IEC 61499-based application on a demonstrator system to highlight the possibilities of this new automation standard.

The project resulted in a 50% reduction in the effort required for developing control software compared to traditional automation approaches. This significant improvement in development efficiency demonstrates the practical benefits of standardized, portable automation components and validates the universal automation concept for smaller industrial enterprises.

Digital Twin Integration and Advanced Analytics

Seamless Integration with Digital Twin Technologies

EcoStruxure Automation Expert’s architecture facilitates seamless integration with digital twin technologies, enabling organizations to create comprehensive virtual representations of their physical systems. The platform’s compatibility with EcoStruxure Machine Expert Twin allows engineers to develop, test, and validate automation applications in virtual environments before deployment to physical systems.

This digital twin integration delivers substantial benefits throughout the system lifecycle. Engineers can perform virtual commissioning, dramatically reducing on-site commissioning time and costs while identifying potential issues before they impact production operations. The ability to simulate complete operations, including what-if scenarios, enables organizations to optimize their processes and anticipate system behavior under various operating conditions.

The virtual testing capabilities eliminate common commissioning challenges such as spending weeks checking HMI interfaces, forcing PLC inputs and outputs, and cross-referencing test plans. Instead of discovering problems during the physical commissioning phase, engineers can simulate systems, identify issues, address them in the virtual environment, and use simulation tools to analyze system responses in slow motion.

AI-Powered Analytics and Predictive Maintenance

The platform’s integration with artificial intelligence capabilities enables advanced analytics and predictive maintenance functionality that was previously difficult to implement in traditional automation systems. The AI functions support visual inspections, anomaly detection, and pattern recognition that can identify potential equipment failures before they occur.

These AI-powered capabilities integrate seamlessly with the automation system’s real-time data streams, providing continuous monitoring and analysis of system performance. Organizations can leverage machine learning algorithms to optimize process parameters, reduce energy consumption, and improve overall equipment effectiveness (OEE) without requiring extensive custom programming or third-party analytics platforms.

EcoStruxure Machine SCADA Expert software interface displayed on a computer monitor, showcasing Schneider Electric’s industrial automation solution

Technical Architecture and Standards Compliance

IEC 61499 Standard Implementation

The IEC 61499 standard forms the foundation of EcoStruxure Automation Expert’s revolutionary approach to industrial automation. This international standard defines a generic model for distributed control systems and extends the capabilities of the widely adopted IEC 61131 standard, enabling portable, interoperable automation applications across different hardware platforms.

IEC 61499’s event-driven architecture supports both process and factory automation paradigms, potentially converging the worlds of industrial automation and embedded systems. The standard enables extensive preprocessing and testing of applications through software tools, allowing engineers to validate and test automation applications before deployment to physical systems.

The standard’s abstract design allows different industrial segments to insert industry-specific preferences such as communication protocols and data models. This flexibility accommodates a wide range of industrial use cases rather than forcing a one-size-fits-all approach, making it suitable for diverse industrial applications from discrete manufacturing to continuous process control.

Open Architecture and Interoperability

EcoStruxure Automation Expert’s open architecture eliminates the barriers created by proprietary automation systems, enabling communication across different machines, devices, and sensors from multiple vendors. This interoperability is achieved through standardized communication protocols and data models that ensure seamless integration regardless of hardware manufacturer.

The platform supports established software best practices that simplify the creation of automation applications capable of interoperating with IT systems. This IT/OT convergence enables organizations to leverage existing enterprise software investments while extending automation capabilities to cloud-based analytics and enterprise resource planning (ERP) systems.

The open architecture approach provides organizations with unprecedented flexibility in selecting automation components based on performance requirements rather than vendor compatibility constraints. This freedom enables the adoption of best-in-class technologies and promotes innovation through competitive supplier ecosystems.

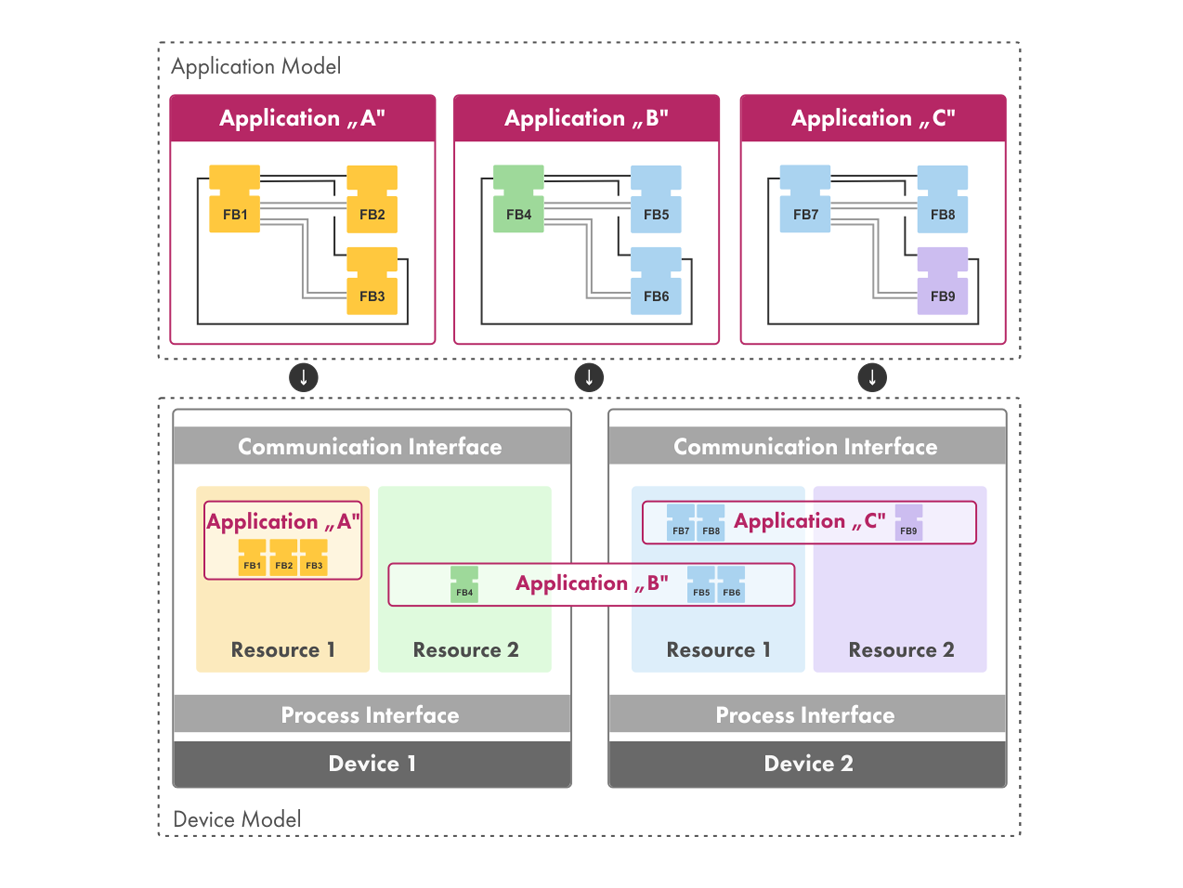

Diagram of IEC 61499-based universal automation showing modular applications distributed across devices and resources with communication and process interfaces

Economic Benefits and Return on Investment

Quantifiable Performance Improvements

Organizations implementing EcoStruxure Automation Expert report significant and measurable improvements across multiple operational metrics. The platform delivers 3x faster application creation compared to traditional automation systems, dramatically reducing engineering time and accelerating project delivery. This improvement stems from the platform’s object-oriented development environment and reusable software components that eliminate redundant engineering work.

Diagnostic capabilities show even more impressive improvements, with users experiencing 6x faster diagnostics when troubleshooting system issues. This enhanced diagnostic speed reduces system downtime and enables maintenance teams to quickly identify and resolve operational problems before they impact production schedules.

Perhaps most significantly, organizations achieve 7x faster production alterations when implementing process changes or optimizations. This agility enables manufacturers to respond rapidly to market demands, implement continuous improvement initiatives, and adapt production processes without extended downtime periods.

Cost Reduction and Efficiency Gains

The economic benefits of EcoStruxure Automation Expert extend beyond operational improvements to deliver substantial cost reductions across multiple categories. Organizations report up to 70% improved engineering efficiency through the platform’s automated low-value engineering tasks and reusable software components. This efficiency improvement allows engineering teams to focus on high-value innovation rather than repetitive configuration work.

Recovery time after system faults shows an impressive 80% reduction compared to traditional automation systems. This dramatic improvement in system resilience reduces production losses associated with unplanned downtime and minimizes the impact of equipment failures on overall manufacturing effectiveness.

Some organizations have achieved up to 100% return on investment (ROI) in less than three months of implementation. This rapid payback period makes EcoStruxure Automation Expert an attractive investment for organizations seeking to modernize their automation infrastructure while maintaining strict capital expenditure controls.

Long-Term Strategic Value

Beyond immediate operational benefits, EcoStruxure Automation Expert provides significant long-term strategic value through its evergreen architecture approach. The platform effectively decouples hardware and software lifecycles, enabling organizations to extend system lifetime expectancy beyond the availability of hardware spares or active operating system support.

This decoupling transforms traditional capital expenditure (CapEx) automation investments into more flexible operational expenditure (OpEx) models. Organizations can implement extensions, upgrades, and system evolutions through software updates rather than major hardware revamps, reducing the total cost of ownership over the system’s operational lifetime.

The platform’s multi-vendor collaboration capabilities provide both technical and business perspective benefits. Organizations can leverage competitive supplier ecosystems to optimize costs while maintaining system integration and performance standards.

Digital twin technology illustrating the integration of virtual models with real-world industrial automation processes in a smart factory environment

Future-Proofing Industrial Operations

Embracing Industry 4.0 and Smart Manufacturing

EcoStruxure Automation Expert positions organizations at the forefront of Industry 4.0 transformation by providing the technological foundation necessary for smart manufacturing implementations. The platform’s software-defined approach enables seamless integration of emerging technologies such as artificial intelligence, machine learning, and advanced analytics into existing automation infrastructure.

The system’s cloud-native architecture supports hybrid deployment models that combine on-premises control with cloud-based analytics and optimization services. This flexibility enables organizations to leverage cloud computing benefits while maintaining the real-time performance requirements essential for industrial control applications.

Digital transformation initiatives benefit significantly from the platform’s ability to create a single digital thread from operational technology (OT) to information technology (IT) systems. This integration enables data-driven decision-making and supports advanced manufacturing concepts such as mass customization and adaptive production systems.

Sustainability and Environmental Impact

The platform contributes significantly to industrial sustainability objectives by enabling more efficient resource utilization and energy management. Organizations can integrate new energy solutions and renewable energy systems without overhauling entire automation architectures, supporting corporate sustainability goals and regulatory compliance requirements.

Energy optimization capabilities built into the platform help organizations reduce energy consumption through real-time optimization and predictive control algorithms. Studies indicate that digitization through platforms like EcoStruxure can result in average energy consumption savings of 24%, with some industrial applications achieving up to 50% productivity improvements through energy management and automation efficiencies.

The platform’s lifecycle extension capabilities for existing automation hardware reduce electronic waste and support circular economy principles. By enabling software updates and functionality enhancements on existing hardware platforms, organizations can extend equipment lifecycles while reducing environmental impact and capital expenditure requirements.

Implementation Strategy and Best Practices

Migration Planning and Risk Mitigation

Successful implementation of EcoStruxure Automation Expert requires careful planning and a structured approach to migration from existing automation systems. Organizations should begin with pilot implementations on non-critical systems to validate performance benefits and develop internal expertise before expanding to mission-critical applications.

The platform’s hardware-independent design enables phased migration strategies that minimize operational risk and investment requirements. Organizations can maintain existing hardware while gradually updating software components, allowing for seamless transitions without production interruptions.

Change management considerations are crucial for successful adoption, as the shift to software-centric automation requires new skills and engineering approaches. Training programs should focus on object-oriented development methodologies, digital twin technologies, and integrated IT/OT systems management.

Maximizing Platform Benefits

To realize the full potential of EcoStruxure Automation Expert, organizations should focus on developing standardized automation libraries that leverage the platform’s reusability capabilities. These libraries enable rapid deployment of proven automation solutions while maintaining consistency across multiple sites and applications.

Integration with enterprise systems should be prioritized to maximize the value of data generated by the automation platform. The platform’s native support for modern communication protocols facilitates seamless connectivity with enterprise resource planning (ERP), manufacturing execution systems (MES), and business intelligence platforms.

Organizations should also invest in digital twin development capabilities to fully leverage the platform’s virtual commissioning and optimization features. These investments deliver significant returns through reduced commissioning time, improved system reliability, and enhanced operator training capabilities.

EcoStruxure Automation Expert represents a revolutionary advancement in industrial automation technology that fundamentally transforms how organizations approach manufacturing and process control. Through its software-centric architecture, standards-based interoperability, and advanced integration capabilities, the platform delivers measurable performance improvements while positioning organizations for future technological developments. The combination of immediate operational benefits and long-term strategic value makes EcoStruxure Automation Expert an essential platform for organizations seeking to thrive in the era of digital manufacturing and Industry 4.0 transformation.