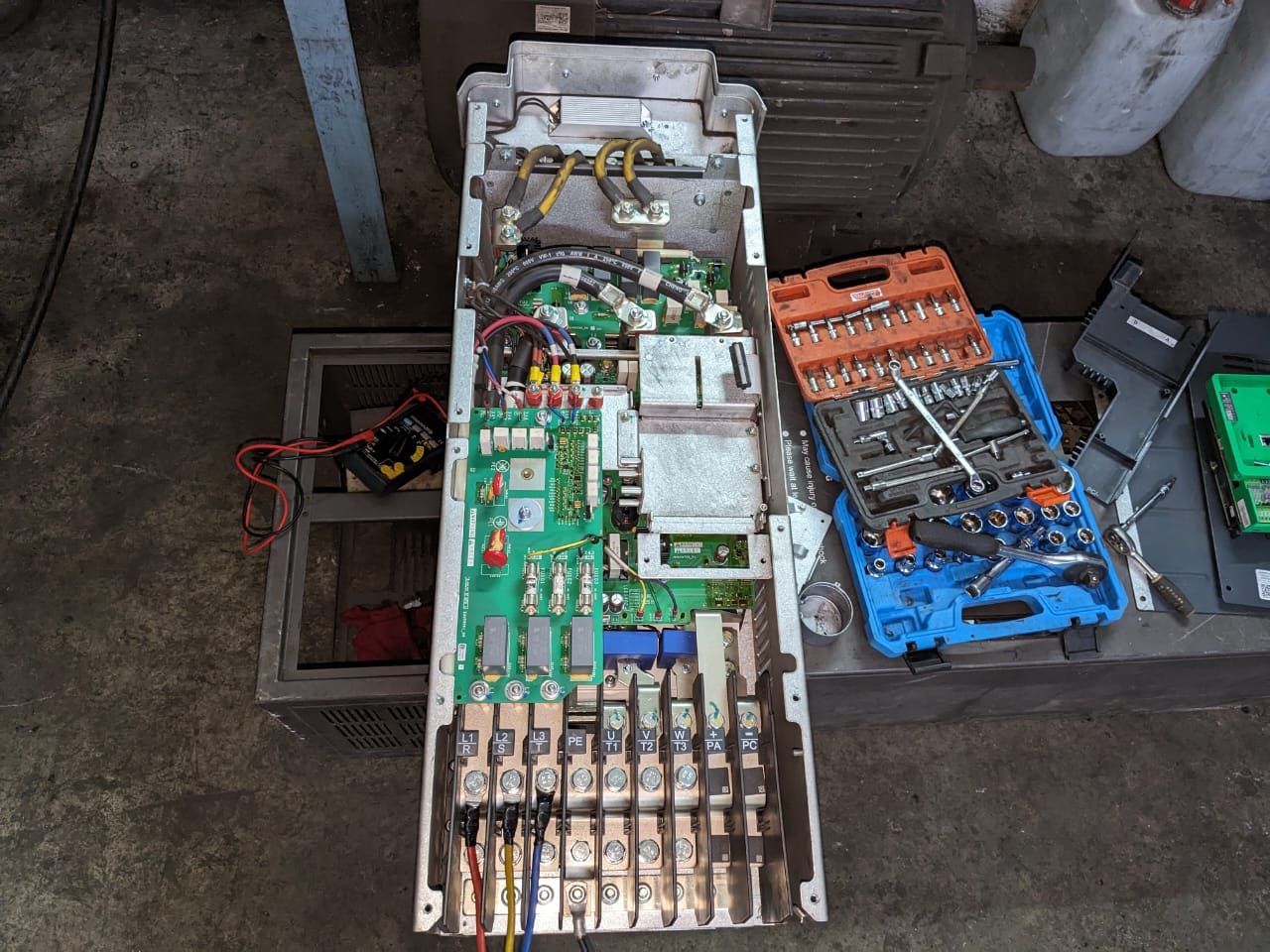

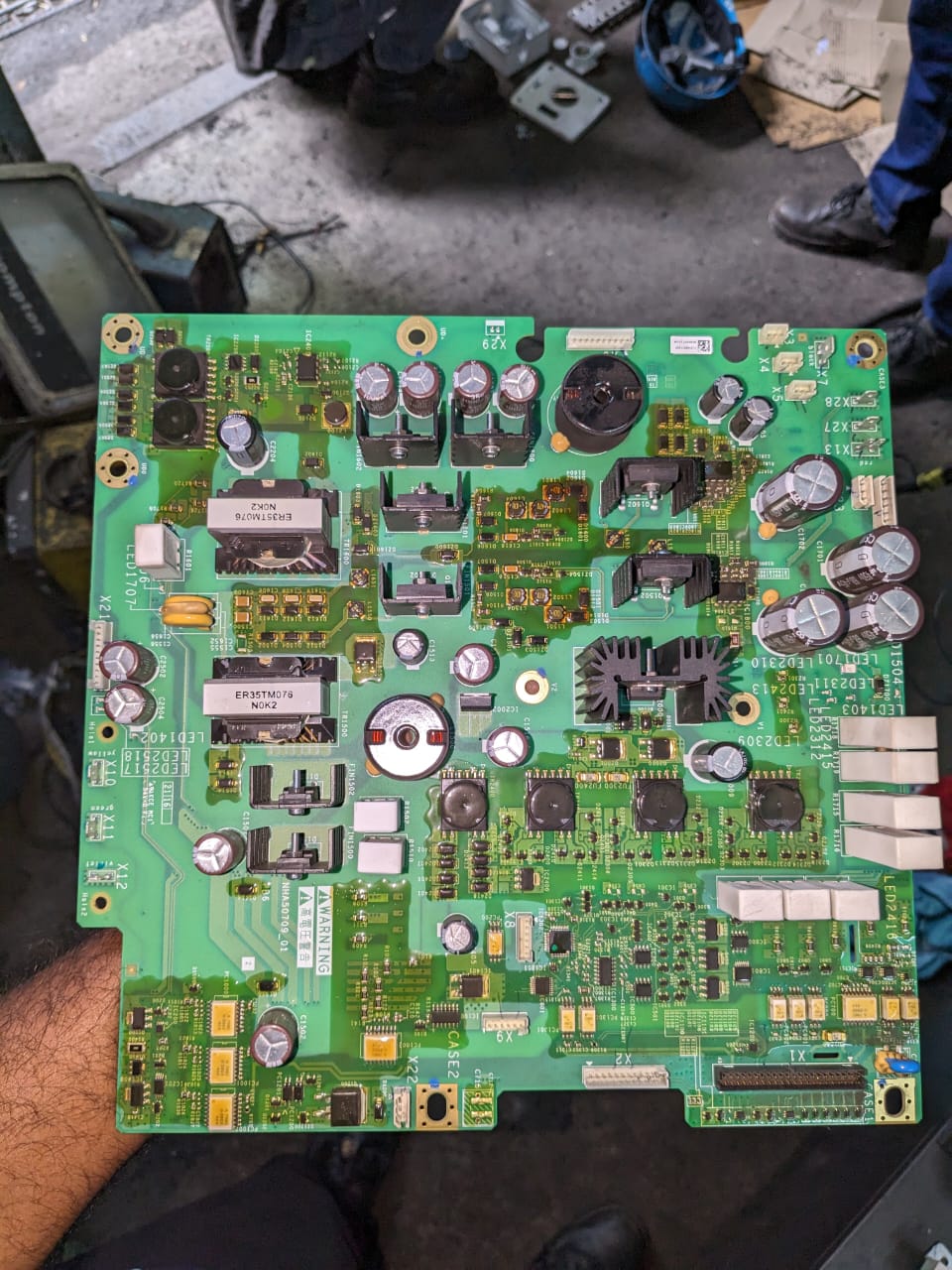

Power board

There are several reasons why you might need to change the power board in an ATV630 variable frequency drive (VFD)

Malfunction or Failure:

If the power board is malfunctioning, damaged, or has completely failed, it can significantly impact the operation of the VFD. Symptoms of a faulty power board may include erratic behavior, frequent trips or faults, voltage irregularities, or no output. In such cases, replacing the power board is necessary to restore proper functionality and ensure the reliable operation of the VFD.

Overheating or Thermal Issues:

Powerboards in VFDs can sometimes experience overheating due to prolonged usage, inadequate cooling, or environmental factors. Overheating can lead to component degradation and reduced performance. If thermal issues persist despite attempts to address them through proper cooling measures, replacing the power board may be necessary.

Upgrades or Enhancements:

There may be instances where replacing the power board is part of an upgrade or enhancement initiative. Upgrading the power board could involve using a newer version with improved components or enhanced features, leading to better performance, efficiency, or compatibility with newer technologies.

Compatibility or Configuration Changes:

In certain cases, changing the power board may be required to address compatibility issues or accommodate changes in the VFD configuration. For example, if you need to adapt the VFD to a different power supply or voltage rating, a compatible power board replacement might be necessary.

Preventive Maintenance:

As part of routine maintenance or preventive measures, changing the power board at regular intervals might be recommended. This helps ensure the longevity and reliability of the VFD by proactively replacing aging components before they fail.

It is crucial to consult with Schneider Electric or a certified service technician with expertise in VFDs for accurate diagnosis and guidance regarding the need for a power board replacement. They can help assess the specific situation, determine if a power board replacement is necessary, and provide assistance in selecting and installing the appropriate replacement board.

Additionally, it’s essential to follow proper safety procedures when working with electrical equipment. Ensure that the VFD is de-energized and disconnected from the power supply before attempting any maintenance or replacement activities.

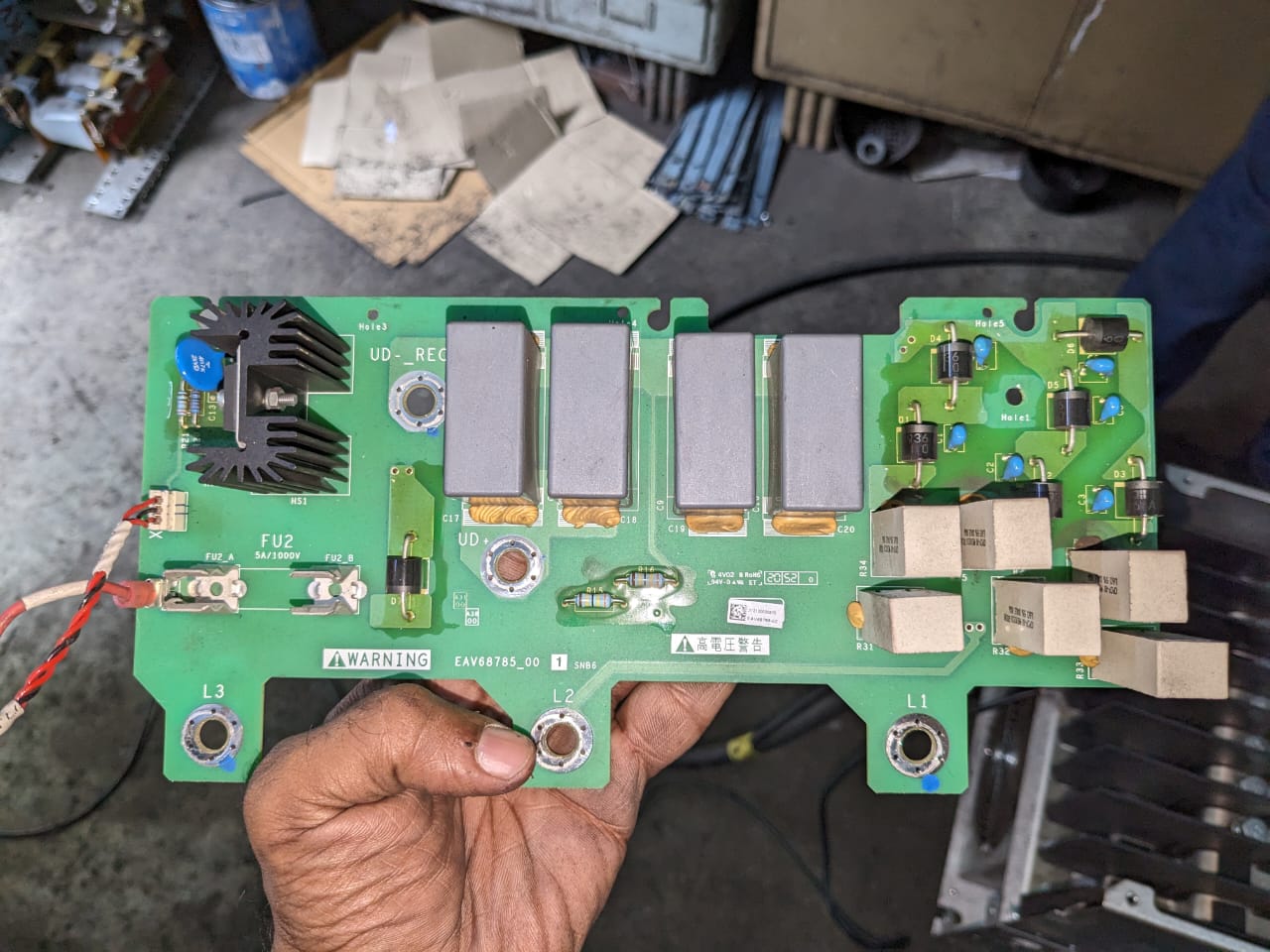

Rectifier Snubber board

After installing a new power board and rectifier snubber board in an ATV630 variable frequency drive (VFD), the Service Tab request may still be necessary for the following reasons.

There could be several reasons why you might need to change the rectifier snubber board in an ATV630 variable frequency drive (VFD). Here are a few possible scenarios:

Malfunction or Failure:

If the rectifier snubber board is malfunctioning or has completely failed, it can result in improper voltage spike suppression or increased electromagnetic interference (EMI). This can impact the overall performance and reliability of the VFD. In such cases, replacing the faulty rectifier snubber board becomes necessary to restore proper functionality.

Voltage Transients or EMI Issues:

If you are experiencing significant voltage transients or EMI within the VFD system, it could be an indication of problems with the rectifier snubber board. The rectifier snubber board is designed to suppress voltage spikes and reduce EMI. If it is not functioning correctly, it may not effectively mitigate these electrical disturbances, leading to operational issues. Replacing the rectifier snubber board can help address these problems.

Enhanced Performance or Upgrades:

In some cases, replacing the rectifier snubber board may be done to enhance the performance of the VFD or to upgrade to a newer version of the board. Upgraded or advanced rectifier snubber boards might offer improved protection against voltage spikes, enhanced EMI suppression, or other features that can optimize the VFD’s operation. This can result in improved overall system performance and reliability.

Maintenance and Preventive Measures:

As part of regular maintenance or preventive measures, replacing the rectifier snubber board might be recommended. Over time, the components on the board may degrade, affecting their performance and effectiveness. By replacing the rectifier snubber board proactively, you can ensure that the VFD remains in optimal working condition and prevent potential issues.

It’s important to note that the decision to change the rectifier snubber board should be based on thorough troubleshooting and assessment of the specific issue or requirement. Consulting with Schneider Electric or a certified service technician who has expertise in VFDs is highly recommended. They can accurately diagnose the problem, provide guidance on whether a board replacement is necessary, and assist with the correct installation and configuration of the new rectifier snubber board.

Why need a Service Tab request?

Configuration Validation:

The Service Tab allows technicians to verify that the new power board and rectifier snubber board are recognized by the VFD and are functioning correctly. It provides access to configuration settings that ensure proper communication and synchronization between the boards and the VFD’s control system.

Parameter Adjustment:

Installing new power and rectifier snubber boards may require adjustments to specific parameters within the VFD. The Service Tab provides access to advanced parameter settings, allowing technicians to fine-tune parameters related to motor control, current limits, voltage regulation, or other characteristics specific to the new boards.

Diagnostic Checks:

After installing new boards, it’s important to perform diagnostic checks to ensure proper functionality and identify any potential issues. The Service Tab provides access to diagnostic information, such as fault codes or alarms, allowing technicians to diagnose and troubleshoot any problems related to the new boards.

Firmware Updates:

Depending on the compatibility and version requirements of the new boards, a firmware update may be necessary for the VFD. The Service Tab allows for the installation of firmware updates, ensuring that the VFD operates with the latest software version that is compatible with the new boards.

Calibration or System Integrity Checks:

Installing new boards may require calibrating certain components or conducting system integrity checks. The Service Tab can provide access to calibration routines or self-diagnostic tests to ensure that the new boards are properly calibrated and integrated into the VFD’s control system.

By accessing the Service Tab after installing new power and rectifier snubber boards in the ATV630 VFD, technicians can validate the configuration, adjust parameters as necessary, perform diagnostic checks, update firmware if needed, and ensure the overall integrity and compatibility of the system. These steps are crucial for the reliable and optimal operation of the VFD with the new boards in place.