” Schneider EcoStruxure Automation Expert (EAE) is the world’s first software-centric industrial automation system based on the IEC 61499 standard. It enables universal automation by decoupling control software from hardware, allowing flexible, reusable, and interoperable engineering across platforms. Designed for Industry 4.0, EAE integrates digital twins, edge computing, and cloud connectivity to simplify lifecycle management and accelerate digital transformation. Whether for process industries, hybrid plants, or discrete manufacturing, Schneider EAE delivers unmatched efficiency, openness, and scalability for future-ready operations. “

Introduction

In the era of digital transformation and Industry 4.0, industrial automation systems are expected to be modular, interoperable, and software-driven. Traditional control architectures—built around proprietary PLCs and fixed hardware—often limit flexibility and innovation.

This is where Schneider EcoStruxure Automation Expert (EAE) sets a new benchmark.

Schneider EcoStruxure Automation Expert (EAE) is the world’s first software-centric industrial automation system based on the IEC 61499 standard, designed to enable universal automation. It decouples control software from hardware, allowing engineers to build reusable, portable, and hardware-agnostic applications.

In essence, EAE represents the next generation of industrial control systems, offering freedom, scalability, and full IT/OT convergence.

What is Schneider EcoStruxure Automation Expert (EAE)?

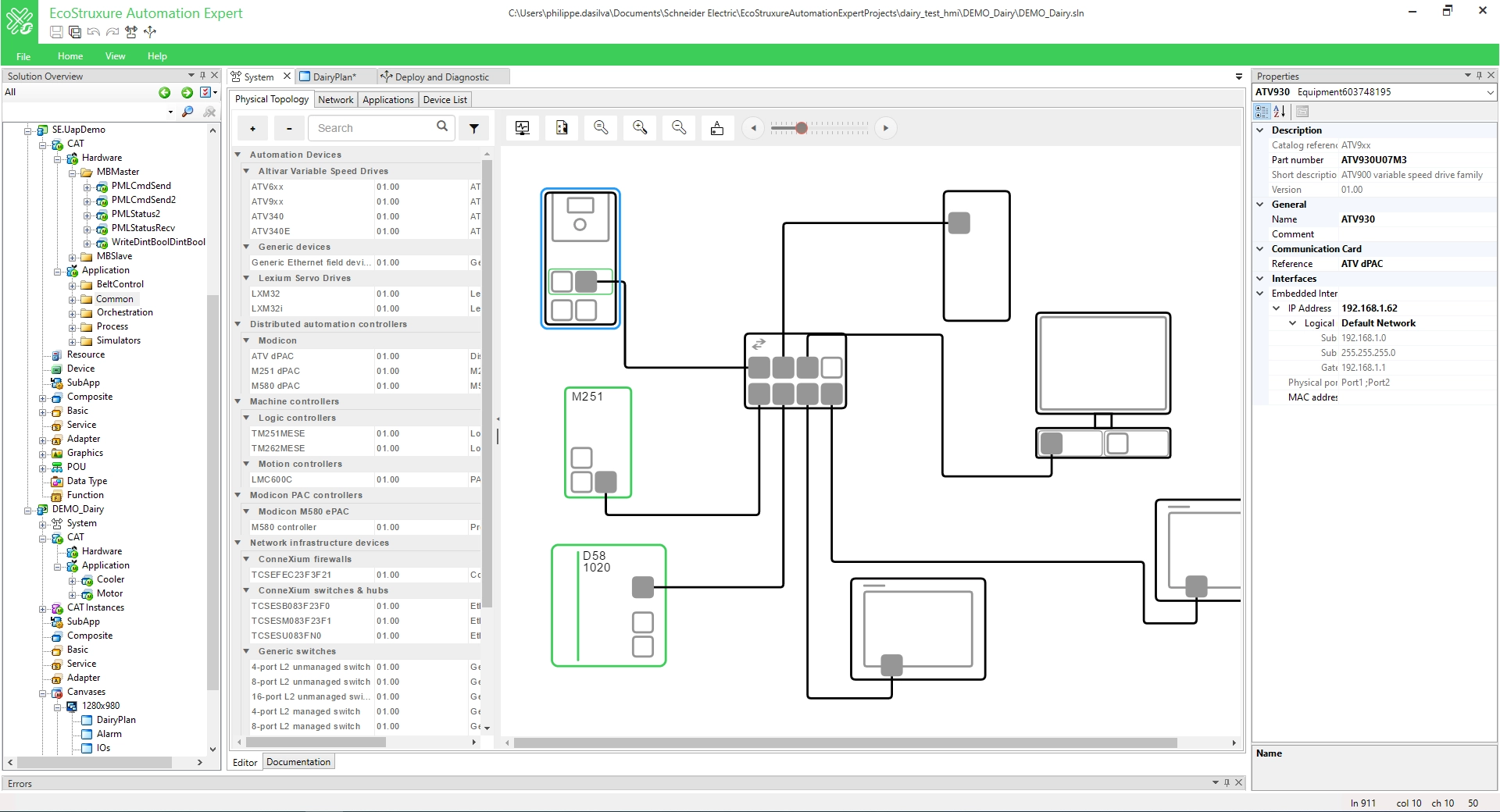

Schneider EcoStruxure Automation Expert (EAE) is an open, software-defined automation platform developed by Schneider Electric to modernize the way control systems are engineered, deployed, and maintained.

Unlike conventional PLC-based systems that are hardware-bound, EAE is fully software-driven and supports object-oriented programming under IEC 61499. This means that automation functions can be created once and deployed anywhere—whether on edge controllers, virtual machines, or cloud environments.

The platform is part of Schneider Electric’s broader EcoStruxure architecture, which integrates connected products, edge control, and analytics under a unified digital ecosystem.

Core Architecture of EAE – Built on IEC 61499

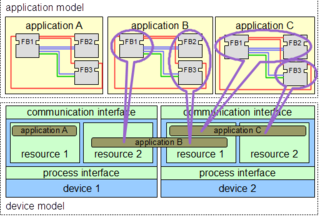

At the heart of EcoStruxure Automation Expert lies the IEC 61499 standard, which introduces event-driven and distributed control design. This is a major departure from the older IEC 61131-3 model used in most PLC systems.

Event-Driven Execution

IEC 61499 enables event-based execution, allowing control logic to react instantly to process changes. This ensures real-time responsiveness and optimized performance.

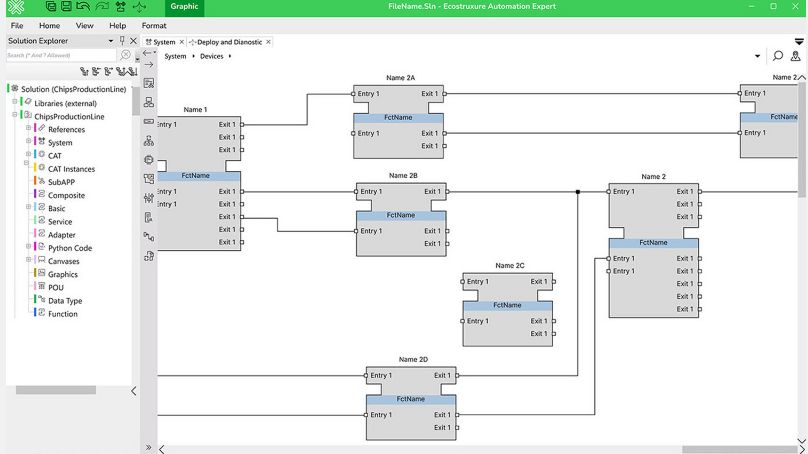

Function Blocks as Reusable Components

In EAE, automation logic is structured into function blocks—self-contained components that can be reused across different applications or hardware platforms. This modularity speeds up development and enhances maintainability.

Hardware Independence

Because control applications are decoupled from the hardware, they can be deployed on multiple devices without rewriting code. This is the essence of universal automation.

Distributed System Design

EAE supports distributed deployment, meaning control functions can be spread across multiple devices or virtual instances—ideal for scalable, decentralized systems.

Key Features of Schneider EcoStruxure Automation Expert (EAE)

- Open IEC 61499 Architecture

- Enables modular, event-driven programming.

- Facilitates true interoperability and vendor independence.

- Universal Automation Compatibility

- Designed to work with multiple vendor systems through the UniversalAutomation.org ecosystem.

- Software-Centric Engineering Environment

- Engineers design logic once and deploy anywhere—from field controllers to virtual machines.

- Digital Twin Integration

- Simulate, validate, and test control applications in a virtual environment before deploying them.

- Cloud and Edge Connectivity

- Seamlessly integrate with edge computing and IoT platforms for predictive maintenance and real-time analytics.

- Lifecycle Management Tools

- Manage version control, upgrades, and maintenance through centralized engineering tools.

- Cybersecurity by Design

- EAE integrates Schneider’s cybersecurity framework, ensuring data integrity and secure connectivity.

Benefits of Schneider EcoStruxure Automation Expert (EAE)

1. Reduced Engineering Effort

With reusable function blocks and object-oriented design, engineers spend less time coding repetitive logic. Engineering time can be reduced by up to 50%, especially in large-scale process industries.

2. Faster Commissioning

The digital twin environment allows pre-validation of logic, reducing errors during commissioning and start-up.

3. Greater Flexibility and Scalability

EAE adapts easily to changing production requirements without major reprogramming. You can scale from a single device to plant-wide systems.

4. Hardware Independence

No longer tied to a specific PLC or DCS. Engineers can select the best-fit hardware based on performance, not compatibility.

5. Interoperability and Openness

As part of the UniversalAutomation.org initiative, EAE ensures that systems from different vendors can work together seamlessly.

6. Lower Total Cost of Ownership (TCO)

Reduced engineering hours, faster maintenance, and hardware flexibility significantly lower the lifetime system cost.

7. Future-Proof Design

EAE supports emerging technologies like AI-based control, machine learning analytics, and remote operations, making it ready for future industrial challenges.

Applications of Schneider EcoStruxure Automation Expert (EAE)

| Industry | Use Case | Advantages |

|---|---|---|

| Process Automation | Oil & Gas, Water Treatment, Food & Beverage | Simplified logic design, reduced downtime |

| Discrete Manufacturing | Automotive, Packaging, Electronics | Quick reconfiguration for new product lines |

| Hybrid Systems | Pharma, Chemical, Energy | Unified control for batch and continuous processes |

| Building Automation | HVAC, Lighting, Energy Management | Integrated control for smart buildings |

| Utilities | Smart grids, Renewable plants | Edge-based monitoring and predictive analytics |

How EAE Enables Universal Automation

The concept of universal automation is central to Schneider’s EAE philosophy. It aims to create an open ecosystem where automation applications are portable, interoperable, and reusable across any compliant system.

1. Decoupling Software from Hardware

Traditional automation ties software tightly to the controller. EAE breaks this link, giving engineers freedom to move applications between devices.

2. Vendor-Neutral Engineering

Through the UniversalAutomation.org framework, EAE ensures open standards and prevents vendor lock-in.

3. IT/OT Convergence

EAE integrates industrial control with IT infrastructures, allowing data sharing, analytics, and cloud integration for smarter decision-making.

Integration with EcoStruxure Architecture

EAE is part of Schneider Electric’s EcoStruxure architecture, which has three main layers:

- Connected Products – Field devices, sensors, and actuators.

- Edge Control – Controllers and gateways running EcoStruxure Automation Expert.

- Apps, Analytics & Services – Cloud-based dashboards and AI analytics.

Together, these layers enable real-time monitoring, predictive maintenance, and optimized energy management—creating a closed loop of data and control.

Digital Twin and Simulation Capabilities

EcoStruxure Automation Expert provides built-in tools for virtual commissioning through digital twins. Engineers can model physical processes, test control logic, and fine-tune performance—all before deployment.

Benefits include:

- Fewer on-site test iterations.

- Reduced commissioning time by up to 60%.

- Improved reliability and process safety.

Future Outlook – Software-Defined Automation

The industrial automation landscape is shifting from hardware-centric to software-defined control. EAE represents this evolution by aligning with open standards, flexible architectures, and cross-platform integration.

As industries adopt edge intelligence and AI-based optimization, platforms like Schneider EcoStruxure Automation Expert (EAE) will form the backbone of future smart factories.

Conclusion

In today’s fast-changing industrial landscape, flexibility, openness, and intelligence are the foundations of future automation. Schneider EcoStruxure Automation Expert (EAE) delivers exactly that — a truly software-centric, IEC 61499-based platform that transforms how control systems are designed, deployed, and managed.

By decoupling software from hardware, Schneider EcoStruxure Automation Expert (EAE) enables engineers to create modular, reusable, and interoperable automation solutions that adapt easily to any environment — from the factory floor to the edge or cloud. Its integration with digital twins, universal automation, and EcoStruxure architecture empowers industries to achieve higher productivity, faster commissioning, and reduced lifecycle costs.

For organizations embracing Industry 4.0 and digital transformation, Schneider EcoStruxure Automation Expert (EAE) is more than an automation tool — it’s the gateway to smart, sustainable, and future-ready industrial operations.

FAQ Section – Schneider EcoStruxure Automation Expert (EAE)

1. What is Schneider EcoStruxure Automation Expert (EAE)?

Schneider EcoStruxure Automation Expert (EAE) is a software-defined industrial automation system that uses the IEC 61499 standard to enable open, modular, and event-driven control applications. It separates software from hardware, promoting flexibility, reusability, and vendor-neutral engineering.

2. What makes EcoStruxure Automation Expert different from traditional PLC systems?

Unlike conventional PLCs that rely on proprietary hardware and IEC 61131 programming, EAE uses IEC 61499, an object-oriented, event-driven model. This allows engineers to deploy the same application across multiple devices or virtual environments without rewriting code.

3. What industries can benefit from Schneider EcoStruxure Automation Expert (EAE)?

EAE is ideal for process industries (oil & gas, water treatment, food & beverage), discrete manufacturing (automotive, packaging, electronics), hybrid plants, and building automation where flexible and interoperable control systems are required.

4. Does EAE support digital twins and simulation?

Yes. EAE includes built-in digital twin capabilities that allow engineers to simulate and validate control logic before deployment. This reduces commissioning time, minimizes risk, and improves overall system reliability.

5. How does EcoStruxure Automation Expert support universal automation?

EAE is part of the UniversalAutomation.org initiative, which ensures open, vendor-independent interoperability. It allows automation applications to be portable and reusable across any compliant system, eliminating vendor lock-in.

6. Is Schneider EcoStruxure Automation Expert compatible with EcoStruxure architecture?

Absolutely. EAE forms the edge control layer of Schneider’s EcoStruxure platform, connecting seamlessly with field devices, analytics, and cloud applications for complete IT/OT convergence.

7. What are the key benefits of adopting EAE?

- Faster engineering and commissioning

- Reduced total cost of ownership (TCO)

- Hardware independence

- Enhanced cybersecurity

- Seamless scalability and reusability

- Preparedness for AI, analytics, and Industry 4.0 evolution

8. Can EAE integrate with existing Schneider Electric systems?

Yes. EAE is designed to coexist with Schneider’s Modicon PLCs, EcoStruxure Control Expert, and other automation environments, enabling a gradual transition to software-centric control architectures.

9. Is EcoStruxure Automation Expert open source?

EAE itself is proprietary to Schneider Electric, but it supports the open UniversalAutomation.org runtime, enabling interoperability with third-party hardware and applications based on IEC 61499.

10. Where can I learn more or download EcoStruxure Automation Expert?

You can explore detailed documentation, trial versions, and technical support on the official Schneider Electric EcoStruxure Automation Expert product page: https://www.se.com/