Top Industrial Automation Trends and Technologies in 2025 | Smart Manufacturing Revolution

Explore the latest Industrial Automation Trends 2025 — from AI, IoT, and Edge Computing to Cobots and Digital Twins. Learn how smart technologies are reshaping manufacturing and industry 4.0.

Introduction: The Rise of Smart Automation

In 2025, industries are evolving faster than ever before. Industrial automation is no longer a futuristic concept—it’s the foundation of every smart factory and intelligent manufacturing process. From automotive to energy, pharmaceuticals to logistics, automation is the key to improving productivity, efficiency, and sustainability.

The Industrial Automation Trends 2025 focus on integrating artificial intelligence (AI), the Internet of Things (IoT), robotics, and data analytics to create a seamless, self-optimizing industrial environment. Machines can now learn, adapt, and predict—minimizing downtime and maximizing output.

As industries continue to embrace Industry 4.0, understanding the latest automation trends becomes crucial for engineers, plant managers, and investors who want to stay ahead of the curve.

1. Artificial Intelligence (AI) and Machine Learning (ML) – The Brain of Automation

AI and ML are redefining industrial automation. These technologies enable machines to analyze large data sets, identify patterns, and make decisions without human intervention.

How AI Shapes Industrial Automation in 2025

- Predictive Maintenance: AI predicts equipment failure before it happens, saving time and costs.

- Automated Quality Inspection: ML models can identify product defects faster and more accurately.

- Energy Optimization: AI algorithms monitor power usage and reduce wastage.

Example:

Automotive manufacturers now use AI to predict assembly line breakdowns, saving millions in downtime losses.

In Industrial Automation Trends 2025, AI is the invisible force driving smarter, safer, and more efficient factories.

2. Industrial Internet of Things (IIoT) – The Power of Connectivity

The Industrial Internet of Things (IIoT) connects machines, sensors, and systems into one intelligent network. With IIoT, data flows seamlessly across all departments, allowing real-time decision-making.

Core Benefits:

- Remote Monitoring: Track machinery performance from any location.

- Data-Driven Insights: Improve maintenance scheduling and resource allocation.

- Energy Efficiency: IIoT-enabled systems monitor energy consumption patterns.

Real-World Example:

Factories equipped with IIoT sensors can detect minor performance drops before they become critical, improving uptime by 20–30%.

The IIoT revolution continues to be one of the strongest industrial automation trends 2025 across manufacturing, oil & gas, and logistics industries.

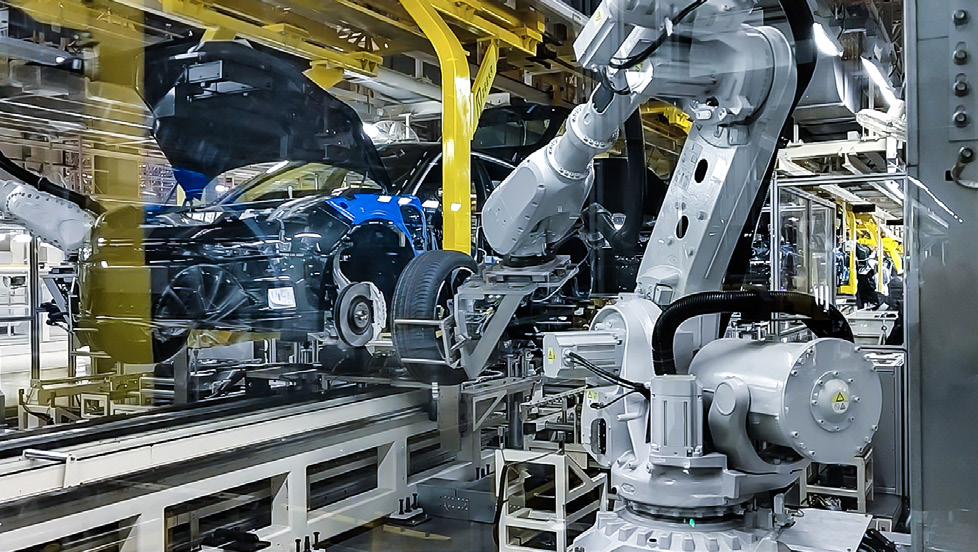

3. Collaborative Robots (Cobots) – Human and Machine Collaboration

Collaborative robots, also known as cobots, are transforming the modern workplace. Unlike traditional robots, cobots are designed to work safely alongside humans.

Key Features of Cobots:

- Easy to program and deploy

- Enhanced safety sensors for human interaction

- Compact, affordable, and energy-efficient

Applications:

- Assembly lines and packaging

- Material handling

- Welding and precision tasks

In 2025, cobots have become more accessible to small and medium-sized enterprises (SMEs), bridging the gap between automation and human creativity.

4. Edge Computing – Faster Decisions, Smarter Operations

Edge computing processes data closer to where it is generated, reducing latency and dependency on the cloud.

Why It’s Vital for Industrial Automation:

- Real-Time Response: Critical operations no longer rely solely on cloud connections.

- Enhanced Security: Sensitive data stays within the factory’s local network.

- Reduced Costs: Less cloud storage means lower operational costs.

For high-speed automation such as robotics, packaging, and process control, edge computing ensures lightning-fast and reliable responses.

5. Digital Twins – Virtual Intelligence in Action

A Digital Twin is a virtual model of a physical process, system, or asset. It mirrors real-world conditions, allowing operators to simulate performance before making physical changes.

Top Benefits of Digital Twins in 2025:

- Early fault detection and predictive maintenance

- Improved production planning

- Real-time process visualization

Industrial Automation Trends 2025 emphasize the growing adoption of digital twins to reduce downtime and enhance operational precision.

6. Cybersecurity – Protecting Industrial Infrastructure

As industries become more connected, cybersecurity is no longer optional. With cyberattacks targeting critical infrastructure, securing industrial systems is a top priority.

Key Strategies:

- Multi-layered network protection

- Encrypted data transfer

- AI-based anomaly detection systems

Organizations investing in cybersecurity can prevent data breaches, equipment sabotage, and production disruptions.

7. Autonomous Mobile Robots (AMRs) – Revolutionizing Material Handling

Autonomous Mobile Robots are replacing traditional conveyors and forklifts with intelligent, self-navigating machines.

Why AMRs Are Trending:

- Flexible navigation with AI-based mapping

- Improved safety through real-time obstacle detection

- Reduced human workload in warehouses

AMRs represent one of the fastest-growing industrial automation technologies 2025, improving logistics efficiency across industries.

8. Sustainability and Energy Efficiency – The Green Automation Movement

Sustainability is a leading force in automation. Manufacturers are now integrating energy-efficient systems, green robotics, and eco-friendly materials into production.

Benefits of Sustainable Automation:

- Lower carbon emissions

- Reduced energy consumption

- Compliance with global green standards

Smart sensors and energy-monitoring tools are helping industries track real-time energy usage, contributing to cleaner, more sustainable production.

9. Cloud-Based Industrial Automation – Anytime, Anywhere Control

Cloud technology is transforming how industrial data is stored, accessed, and analyzed. Cloud-based platforms enable centralized control of operations across multiple plants.

Advantages:

- Easy scalability and data sharing

- Cost-effective system management

- Remote monitoring and updates

By 2025, more industries are integrating automation with cloud computing, leading to faster innovation and real-time collaboration.

10. 5G Connectivity – Speeding Up the Automation Revolution

5G is unlocking new levels of performance for industrial automation systems. Its low latency and high data speeds make it ideal for controlling machines in real-time.

5G Advantages in Automation:

- Instant communication between robots

- Improved accuracy in autonomous operations

- Reliable support for large-scale IoT networks

With 5G-enabled industrial automation technologies, factories can operate with unmatched speed and precision.

11. Advanced SCADA and PLC Integration

Supervisory Control and Data Acquisition (SCADA) systems and Programmable Logic Controllers (PLC) remain the backbone of industrial automation.

2025 Updates:

- Smart SCADA systems integrated with AI analytics

- Cloud-based PLCs for remote configuration

- Predictive alarm systems to minimize downtime

These enhanced control systems form the digital nervous system of every automated plant.

12. Augmented Reality (AR) and Virtual Reality (VR) in Maintenance

AR and VR are becoming valuable tools for remote support and training in industrial environments.

Use Cases:

- Virtual operator training programs

- Remote equipment diagnostics

- On-site maintenance support via AR headsets

Industrial Automation Trends 2025 highlight AR/VR as essential tools for improving workforce efficiency and safety.

Pros and Cons of Industrial Automation in 2025

| Pros | Cons |

|---|---|

| Increases productivity and efficiency | High initial setup cost |

| Reduces human error and downtime | Requires skilled workforce |

| Enables predictive maintenance | Cybersecurity challenges |

| Enhances product quality | Possible job displacement |

| Promotes sustainability and energy savings | Complex integration for legacy systems |

Future Outlook – What’s Next for Industrial Automation Beyond 2025?

Beyond 2025, industrial automation will evolve toward Industry 5.0, where humans and machines collaborate to create personalized, sustainable, and intelligent production systems.

We’ll see further integration of AI-driven robotics, quantum computing, and biomechanical automation—pushing the boundaries of what’s possible in manufacturing and industrial operations.

The industries that adapt early to these Industrial Automation Trends 2025 will lead the future of innovation, efficiency, and profitability.

Frequently Asked Questions (FAQs)

1. What is industrial automation?

Industrial automation involves using control systems such as computers, PLCs, and robots to handle processes with minimal human intervention.

2. What are the top industrial automation trends in 2025?

AI, IIoT, Edge Computing, Cobots, Digital Twins, Cybersecurity, and 5G are the top automation trends shaping 2025.

3. How does automation benefit manufacturing?

It increases production speed, reduces errors, improves safety, and ensures consistent product quality.

4. What industries are adopting automation fastest in 2025?

Automotive, electronics, food processing, logistics, and pharmaceuticals are leading automation adoption.

5. Is industrial automation expensive to implement?

Initial costs can be high, but long-term savings in labor, maintenance, and energy make it cost-effective.

Conclusion

The Top Industrial Automation Trends and Technologies in 2025 represent a new era of intelligent manufacturing. With innovations like AI, IIoT, 5G, and edge computing, industries are becoming more efficient, sustainable, and connected than ever.

Adopting these technologies ensures that companies remain competitive, adaptable, and future-ready in the age of digital transformation.

The journey toward full automation is not just about machines—it’s about creating smarter, safer, and greener industries for the future.