At our company, we understand the importance of insulation tests on electric motors and generators. Proper insulation testing can detect defects and potential weaknesses, ensuring safe and efficient operation of your units. In this section, we will delve into DC High Potential Testing, a powerful method used to assess the insulation quality of electric motors and generators.

DC High Potential Testing involves applying a high voltage to the unit’s insulation and measuring the resulting current flow. By comparing the results to established standards, we can determine the insulation’s integrity and pinpoint any issues requiring corrective action. The test voltage is typically several times the normal operating voltage and can accurately assess insulation quality even in highly stressed areas.

Key Takeaways:

- Insulation tests on electric motors and generators are essential for safe and efficient operation.

- DC High Potential Testing is a powerful method for assessing insulation quality, involving the application of high voltage to the unit’s insulation.

- The test voltage is several times the normal operating voltage and can accurately assess insulation quality even in highly stressed areas.

- DC High Potential Testing can detect defects and potential weaknesses requiring corrective action.

- Utilizing DC High Potential Testing can enhance the reliability and longevity of your electric motors and generators, minimizing downtime and costly repairs.

Understanding Motor and Generator Insulation Testing

At the heart of ensuring the safe and reliable functioning of electric motors and generators lies the ability to assess and maintain insulation integrity. While there are various methods used to evaluate insulation quality, insulation resistance testing, and specifically DC Hipot Testing, remains the most effective technique. By regularly performing these tests, you can detect insulation issues and prevent your machines from malfunctioning, causing costly damages or, worse still, accidents.

Insulation resistance testing involves measuring the resistance of the insulator between the electric motor or generator’s windings and the ground. A low resistance indicates a degraded or compromised insulation condition, signaling the need for corrective action. DC Hipot Testing, on the other hand, measures the voltage required to cause a breakdown in the insulation. This testing method is particularly useful for identifying latent insulation issues that are challenging to detect by conventional testing methods.

Insulation Resistance Testing

Insulation resistance testing is a quick and straightforward method used for periodic checks on electric motors and generators. The test involves using an insulation resistance tester to verify that the insulation resistance between live conductors and ground meets the minimum level required. Typically, the minimum insulation resistance level should be at least one megohm.

The results of insulation resistance tests provide insight into the general condition of the insulation system. In most cases, low insulation resistance indicates a problem with the insulation. The key challenge of insulation resistance tests, however, is that they are only effective in detecting surface leakage issues and are unable to identify insulation weaknesses that may lead to insulation breakdowns.

DC Hipot Testing

DC Hipot Testing is a more rigorous and thorough procedure for measuring insulation integrity, making it an ideal method for identifying insulation weaknesses that may not be detectable through other methods. Like insulation resistance tests, this method also seeks to detect the possibility of excessive leakage to ground.

To perform DC Hipot Testing, an insulation resistance tester is used to measure the insulation resistance of the unit before applying a voltage higher than its rated voltage. This test voltage is maintained for a duration sufficient to check whether the insulation can withstand the voltage without breaking down. A successful DC Hipot Test indicates that the insulation system is robust and that no significant weaknesses are present that could cause electrical breakdown in the future.

It is essential to note that this type of testing requires the use of specialized equipment and should only be performed by trained professionals to prevent electrical hazards and ensure accurate and reliable results.

Insulation testing is a vital aspect of maintaining the safety and optimal performance of electric motors and generators. With proper insulation testing using the right equipment and techniques, you can identify and correct potential issues before they escalate, minimizing costly downtime and repairs.

The Significance of Insulation Resistance in Electric Motors and Generators

Insulation resistance is an essential aspect of ensuring the safe and effective operation of electric motors and generators. Insulation testing is crucial to maintain the integrity of the insulation system and prevent potential catastrophic failures. It is essential to regularly measure and monitor insulation resistance levels as it indicates the condition and quality of the electrical insulation system. Insulation resistance testing is one of the most commonly performed electrical safety tests used to evaluate the quality of the insulation system.

The insulation resistance test measures the resistance of the insulation material between the conductors and the ground. The insulation resistance value is affected by factors such as temperature, humidity, and the condition of the insulation material. High insulation resistance values indicate that the insulation is in good condition and effective in preventing current leakage. Low insulation resistance values imply a significant deterioration of the insulation system, indicating potential hazards that could lead to electrical breakdowns.

The insulation resistance value is an essential parameter in determining the insulation quality of electric motors and generators. Regular insulation testing helps identify and track insulation degradation, allowing you to take corrective measures before catastrophic failures occur. It is recommended to conduct insulation testing at scheduled intervals to maintain optimal insulation resistance levels.

Electrical Safety Testing

Insulation testing falls under electrical safety testing and is mandatory in many industries, including manufacturing, oil, and gas, and pharmaceuticals. These tests are essential in ensuring the safety and reliability of electrical equipment, including electric motors and generators. It helps maintain operational safety, minimize downtime, and prevent potential injuries and fatalities in the workplace.

Insulation resistance testing is just one of the many electrical safety tests performed. Other tests include polarity testing, continuity testing, and grounding resistance testing, to name a few. Electrical safety testing should be performed by trained personnel and in compliance with industry standards and regulations.

In conclusion, insulation resistance is critical for maintaining the safety and performance of electric motors and generators. Regular insulation testing helps identify and track insulation degradation, allowing you to take corrective measures proactively. It is essential to comply with industry standards and regulations when performing insulation testing to ensure accurate and reliable results. Trust us to provide expert insulation testing services, and enhance the insulation quality of your electric motors and generators today.

Introduction to DC High Potential Testing

As we discussed in the previous section, high potential testing is a crucial component of insulation testing for electric motors and generators. DC High Potential Testing, also known as Dielectric Withstand Testing, is a specific method used to evaluate the insulation quality of these units.

The principle behind DC High Potential Testing is relatively simple. The motor or generator is connected to a DC voltage source, typically at a level higher than its rated voltage. The voltage is gradually increased until a predetermined test value is reached or until the insulation breaks down. By analyzing the voltage and current levels, we can determine the overall insulation integrity of the unit.

DC High Potential Testing is particularly valuable for identifying potential insulation defects that may go unnoticed by other methods. It is also useful for detecting weak spots or areas of the insulation that may require further investigation.

Advantages of DC High Potential Testing

Compared to other insulation testing methods, DC High Potential Testing offers several advantages. Firstly, it provides a high level of accuracy, allowing for precise identification of insulation degradation or defects. It can also assess the insulation quality of the entire system, including the stator, rotor, and winding insulation.

Another benefit of DC High Potential Testing is its ability to detect partial discharge, a phenomenon that occurs when insulation defects generate small electrical discharges that can lead to further insulation damage over time. By detecting partial discharge early, corrective measures can be taken to prevent further deterioration of the insulation.

Overall, DC High Potential Testing is an effective and reliable method for assessing the insulation quality of electric motors and generators. By incorporating this testing technique into your maintenance program, you can ensure the longevity and safety of your units.

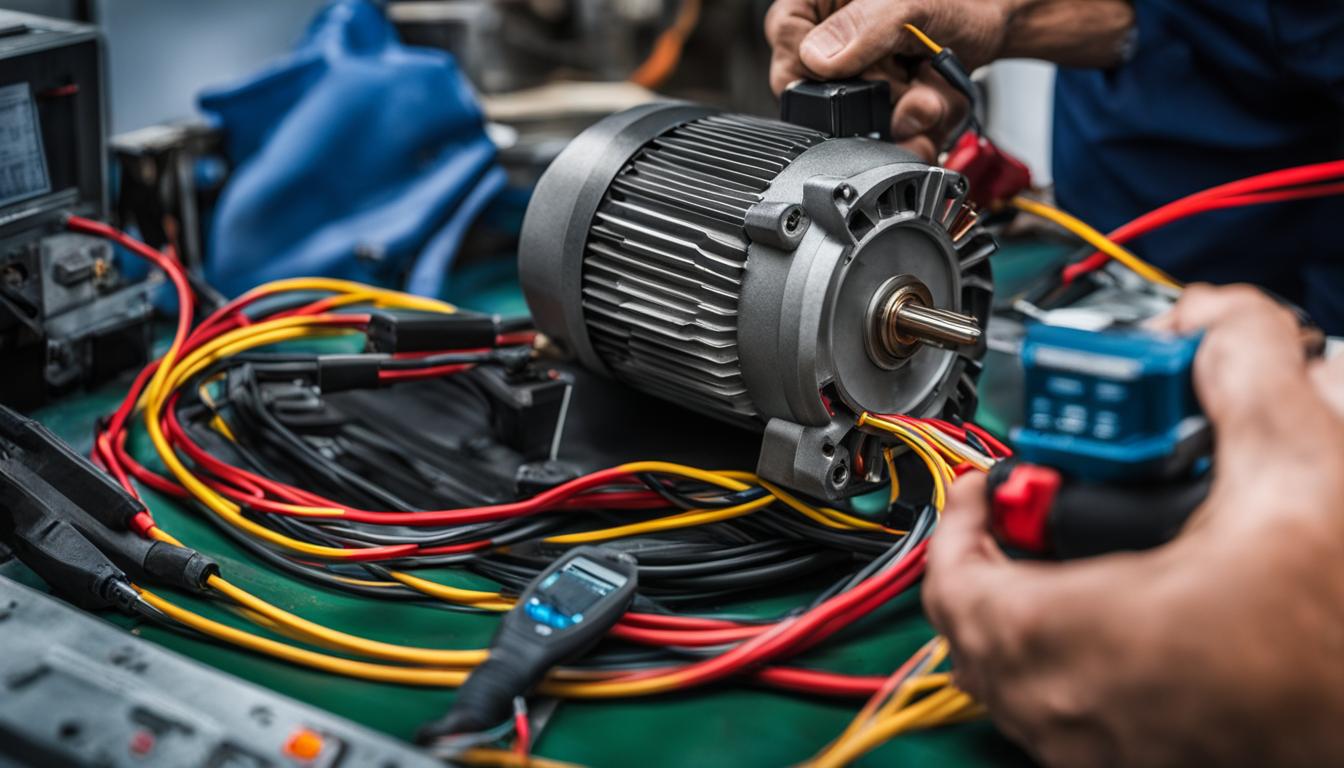

Conducting DC High Potential Testing on Electric Motors

When it comes to motor insulation testing, DC High Potential Testing is one of the most effective methods for detecting potential issues. This test applies high voltage insulation testing to the motor windings to identify weak spots and insulation breakdowns. Follow these steps to ensure accurate and informative results:

- Preparation: Before starting the test, ensure that the motor is properly grounded and that all cables and connections are securely attached. Wear appropriate personal protective equipment, including insulated gloves and a face shield.

- Set-Up: Connect the motor to the testing equipment, including a DC high voltage source, voltmeter, and ammeter. Gradually increase the voltage to the desired level, typically 1.5 times the rated voltage, in accordance with manufacturer recommendations.

- Testing: Monitor the ammeter and voltmeter readings while applying voltage for a set duration, typically one minute. Record the readings and repeat the test with varying voltage levels to identify potential breakdown points.

- Interpretation: Analyze the readings to determine the motor insulation quality and identify any weak spots or potential breakdowns. Use the results to prioritize necessary maintenance and repair actions.

In the event of a breakdown during the test, further insulation breakdown testing may be required to identify the source of the issue. Be sure to follow all recommended safety precautions and seek professional assistance if needed.

Example Table: Insulation Resistance Test Results Before and After DC High Potential Testing

| Motor ID | Insulation Resistance Before DC Hipot Test (MΩ) | Insulation Resistance After DC Hipot Test (MΩ) |

|---|---|---|

| Motor 1 | 5.3 | 8.1 |

| Motor 2 | 3.9 | 6.7 |

| Motor 3 | 6.5 | 7.8 |

This example table showcases the insulation resistance test results before and after DC High Potential Testing. As you can see, all motors experienced an increase in insulation resistance after the test, indicating improved insulation quality. Use this data to track improvements over time and identify motors that may require additional testing or maintenance.

Performing DC High Potential Testing on Generators

Similar to electric motors, generators also require insulation testing to ensure their optimal performance and safety. However, due to their unique construction and operation, there are specific considerations and procedures involved in performing DC High Potential Testing on generators.

Firstly, it’s crucial to ensure that the generator is electrically disconnected and completely de-energized before starting the testing process. This involves disconnecting all the leads from the generator terminals and making sure no residual charge remains. Once the generator is electrically isolated, it’s time to prepare the testing equipment.

For DC High Potential Testing on generators, it’s essential to use equipment that can deliver a high voltage, typically ranging from 1.5 to 3 times the nominal voltage of the generator. The voltage should be increased gradually, while monitoring the leakage current and the insulation resistance value.

It’s important to note that generators are typically larger than electric motors and can have a higher capacitance value. Therefore, the charging current and discharge current of the generator must be taken into account when interpreting the test results.

| Testing Parameters | Acceptance Criteria |

|---|---|

| Leakage Current | Less than 1 mA per kV of applied voltage |

| Insulation Resistance Value | Greater than 1MΩ per kV of nominal voltage |

After completing the DC High Potential Testing, it’s important to analyze the results and understand the implications for the insulation quality of the generator. If the results indicate a low insulation resistance value or high leakage current, it may suggest potential insulation breakdowns or weaknesses. In such cases, corrective actions, such as rewinding the generator or replacing the insulation, may be necessary to ensure the unit’s safety and reliability.

Regular insulation testing, including DC High Potential Testing, can help detect insulation defects and prevent catastrophic failures of both electric motors and generators. By adhering to the recommended practices and using the right testing equipment, you can accurately assess the insulation condition of your units and take appropriate corrective actions if necessary.

Advantages of DC High Potential Testing

At our company, we are proud to offer DC High Potential Testing for insulation quality testing on generators. This method offers several advantages over alternative insulation testing methods, including:

- Ability to detect insulation breakdowns: DC High Potential Testing is an effective way to detect any insulation breakdowns in the system. This is crucial because it allows you to identify any potential weaknesses and take corrective measures promptly, minimizing the risk of unexpected failures.

- Faster and more efficient testing: Compared to other insulation testing methods, DC High Potential Testing is faster and more efficient. This means that you can complete the testing process quickly, reducing downtime and increasing productivity.

- Comprehensive testing: Our DC High Potential Testing is a comprehensive testing method that assesses the entire insulation system. This ensures that you receive a complete and accurate assessment of your generator’s insulation quality.

We understand that generator testing is crucial for the proper functioning of your equipment. That’s why we employ high potential testing to ensure that your generators meet the highest standards for insulation quality.

Best Practices for Insulation Testing on Electric Motors and Generators

Regular insulation testing is essential for maintaining the performance and safety of electric motors and generators. Here are some best practices we recommend for ensuring accurate and reliable insulation tests:

- Schedule routine testing: We recommend performing insulation tests on all electric motors and generators at least once a year. However, factors such as operating conditions and environmental factors may require more frequent testing.

- Choose the appropriate testing method: There are several methods for insulation testing, including insulation resistance testing, polarization index testing, and DC High Potential Testing. Select the method that best suits your needs and equipment type.

- Prepare the unit: Before performing the test, ensure that the unit is clean, dry, and free of any moisture or conducting materials that may affect the test results. Additionally, follow all safety procedures and guidelines to avoid accidents.

- Interpret the results: Once you have conducted the test, interpret the results carefully, taking into account the type of equipment, age, and service life. Consult with a professional if necessary.

- Maintain records: Keep detailed records of all insulation tests performed, including the test date, results, and any corrective measures taken. This information will help you track the unit’s performance and identify any trends or recurring issues.

By following these insulation testing best practices, you can ensure accurate and reliable results, ultimately enhancing the safety and performance of your electric motors and generators.

Conclusion

At [Business Name], we understand the significance of insulation tests on electric motors and generators, and specifically the importance of DC High Potential Testing. By utilizing this testing method, you can detect insulation weaknesses and breakdowns early on, allowing you to take corrective action before any serious damages occur.

Regular insulation testing on your electric motors and generators is crucial for ensuring their optimal performance and safety. Whether it’s motor insulation testing, generator insulation testing, or electrical safety testing, we have you covered. Our experienced professionals use the latest technology and techniques to conduct thorough insulation tests, providing you with accurate and reliable results.

Take advantage of the benefits of DC High Potential Testing and other insulation quality testing methods, including their ability to detect insulation breakdowns and potential weaknesses. By following best practices for insulation testing, you can maximize the efficiency and lifespan of your units, ensuring their continuous and reliable operation.

Trust [Business Name] to provide expert insulation testing services and enhance the insulation quality of your electric motors and generators today. Contact us to schedule your insulation tests and ensure the safety and performance of your units.

FAQ

What are insulation tests on electric motors and generators?

Insulation tests on electric motors and generators are methods used to assess the integrity of the insulation in these units. These tests help identify potential insulation issues and ensure the safety and performance of the equipment.

What is DC High Potential Testing?

DC High Potential Testing is a specific method used for insulation testing on electric motors and generators. It involves applying a high voltage DC current to the insulation to determine its ability to withstand electrical stress.

Why is motor and generator insulation testing important?

Motor and generator insulation testing is important because it helps identify insulation degradation and potential failures. By regularly testing the insulation, you can prevent costly repairs, ensure reliable performance, and maintain electrical safety.

What is the significance of insulation resistance in electric motors and generators?

Insulation resistance is crucial in electric motors and generators as it indicates the condition of the insulation. Monitoring insulation resistance levels helps identify insulation degradation, prevent catastrophic failures, and maintain the overall safety and performance of the equipment.

How does DC High Potential Testing work?

DC High Potential Testing works by applying a high voltage DC current to the insulation of electric motors and generators. This test measures the ability of the insulation to withstand electrical stress and identifies any potential weaknesses or breakdowns.

How can I conduct DC High Potential Testing on electric motors?

To conduct DC High Potential Testing on electric motors, you need to follow proper safety precautions and have the necessary equipment. This includes selecting the appropriate voltage level, setting up the test setup, and interpreting the test results to assess the insulation quality of the motors.

How can I perform DC High Potential Testing on generators?

Performing DC High Potential Testing on generators involves similar considerations as with electric motors. However, there are specific procedures and preparations to ensure accurate assessment of the insulation condition in generators. Following recommended practices is essential to maintain generator performance and safety.

What are the advantages of DC High Potential Testing?

DC High Potential Testing offers several advantages for insulation testing on electric motors and generators. It can detect insulation breakdowns, identify potential weaknesses, and help prevent unexpected failures. By utilizing this method, you can enhance the reliability, longevity, and overall performance of your equipment, minimizing downtime and costly repairs.

What are the best practices for insulation testing on electric motors and generators?

When conducting insulation testing on electric motors and generators, it is important to follow best practices. This includes determining the recommended testing frequency, using common troubleshooting techniques, and implementing proactive maintenance strategies. Following these best practices ensures efficient operation, maximizes equipment lifespan, and minimizes the risk of insulation-related issues.

What is the conclusion of insulation tests on electric motors and generators?

In conclusion, insulation tests on electric motors and generators, specifically through DC High Potential Testing, are essential for ensuring optimum performance and safety. By regularly conducting these tests and analyzing the results, potential insulation defects can be detected early, and corrective measures can be taken promptly. Trust us to provide expert insulation testing services and enhance the insulation quality of your electric motors and generators today.