Welcome to our comprehensive guide on the FLEXHA 5000 Universal I/O system. Whether you’re a seasoned professional or new to industrial configurations, this setup guide will provide you with all the information you need to get started with the FLEXHA 5000. From understanding universal I/O configuration to exploring the software features and specifications, we’ve got you covered.

Key Takeaways:

- The FLEXHA 5000 Universal I/O system is a versatile solution for industrial configurations.

- Our setup guide will walk you through the process step-by-step, ensuring a smooth installation.

- Explore the powerful software features of the FLEXHA 5000 and optimize your configurations.

- Stay up to date with future developments and updates for continuous improvement.

- Leverage natural language processing (NLP) capabilities to simplify and automate your configurations.

Understanding Universal I/O Configuration

Before diving into the setup process of the Flexha 5000 Universal I/O system, it’s crucial to grasp the concept of universal I/O configuration. This section will provide a comprehensive explanation of the principles behind universal I/O configuration, offering you a solid foundation to navigate through the setup and configuration process.

Universal I/O configuration involves the integration of input and output modules within the Flexha 5000 system to facilitate seamless communication and data exchange. By configuring the I/O modules effectively, you can optimize your industrial processes and enhance operational efficiency.

One of the key benefits of universal I/O configuration is its flexibility. The system supports various input and output signal types, allowing you to adapt to different industrial environments and requirements. Whether you need to interface with sensors, actuators, or other devices, the universal I/O configuration of the Flexha 5000 empowers you to achieve seamless integration.

Furthermore, universal I/O configuration simplifies the setup and installation process by standardizing the interface and communication protocols across the system. This streamlines the overall configuration process and ensures compatibility with a wide range of industrial setups.

Key Principles of Universal I/O Configuration

- Signal Mapping: Universal I/O configuration involves mapping input and output signals to the appropriate modules and channels within the Flexha 5000 system. This step ensures that data is accurately captured and transmitted between devices, enabling effective communication and control.

- Data Conversion: To ensure compatibility and seamless data exchange, universal I/O configuration may require data conversion or scaling. This process involves transforming raw input values into meaningful units and formats, facilitating easy interpretation and analysis downstream.

- I/O Module Configuration: Universal I/O configuration encompasses configuring the individual I/O modules within the system. This includes setting up parameters such as signal types, voltage levels, communication modes, and addressing to ensure optimal performance and functionality.

“Understanding the principles behind universal I/O configuration is essential for effectively setting up the Flexha 5000 Universal I/O system. By leveraging the flexibility and versatility of this configuration approach, you can optimize your industrial processes and harness the full potential of the system’s capabilities.”

Universal I/O Configuration in Action

“By employing universal I/O configuration within the Flexha 5000, industrial setups can achieve seamless integration between various devices and systems. This streamlined configuration approach simplifies installation, enhances operational efficiency, and facilitates data-driven decision-making.”

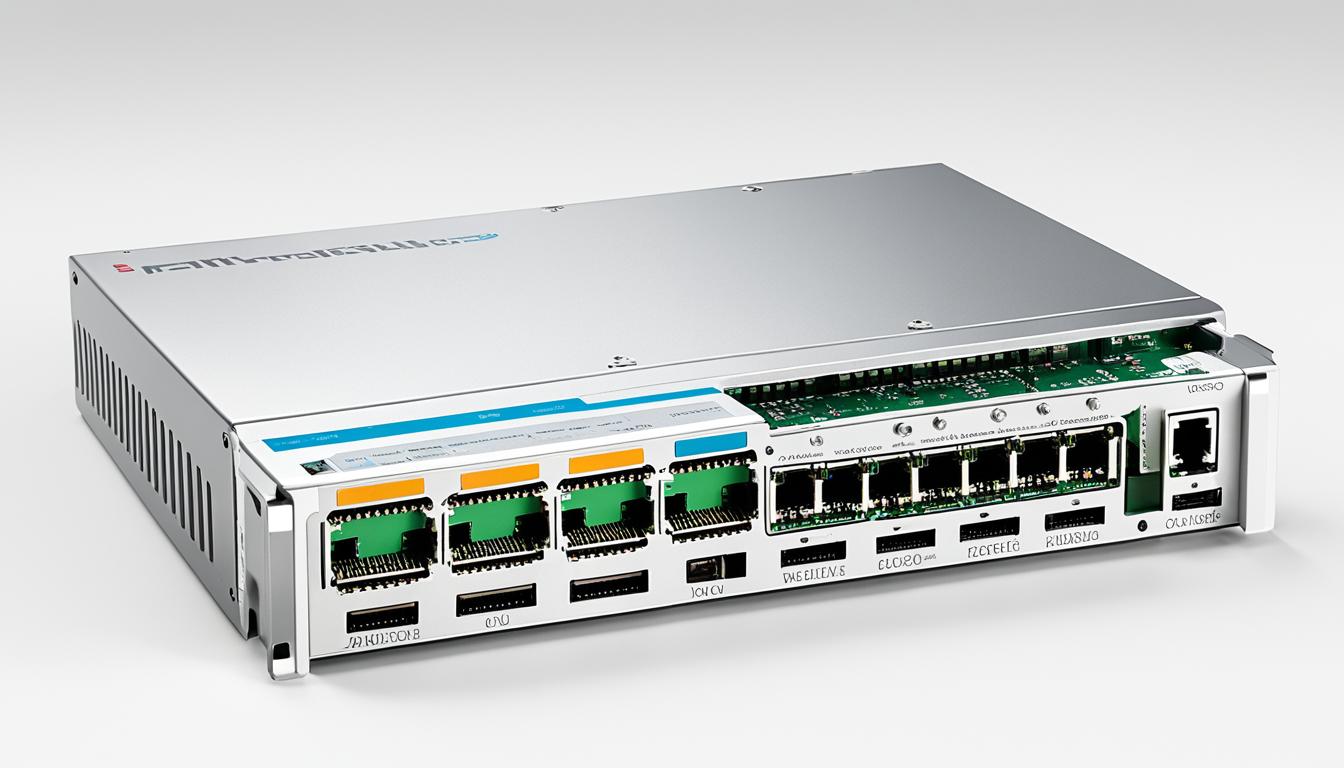

Flexha 5000 Setup and Installation

Setting up and installing the Flexha 5000 Universal I/O system is a straightforward process. In this section, we will guide you through the step-by-step instructions to ensure a smooth and efficient installation. By following this Flexha 5000 setup guide, you’ll be ready to utilize the system’s impressive features in no time.

Gather Required Materials

Before diving into the setup process, it’s essential to ensure you have all the necessary materials on hand. Here is a list of items you’ll need:

- Flexha 5000 Universal I/O modules

- Power supply

- Mounting brackets

- Wiring connectors

- Ethernet cable

Make sure you have everything readily available to avoid any delays during the installation process.

Step-by-Step Setup Guide

Follow these steps to set up and install the Flexha 5000 Universal I/O system:

- Start by identifying the location where you’ll install the Flexha 5000 modules. Ensure it is easily accessible and close to the equipment that requires I/O monitoring and control.

- Attach the mounting brackets to the modules, securing them in place. This step will vary depending on the specific mounting system provided with your Flexha 5000 modules.

- Connect the power supply to the modules, ensuring a secure and stable connection. Refer to the manufacturer’s instructions for the appropriate voltage and power requirements.

- Use the wiring connectors to establish connections between the Flexha 5000 modules and the associated equipment. Verify that the wiring is correctly connected and adequately insulated.

- Connect the Ethernet cable to the designated port on the Flexha 5000 system. This will enable communication and data transfer between the modules and the control software.

- Power on the Flexha 5000 system and verify that all modules are functioning properly. The LED indicators on the modules should indicate their status.

- Install and configure the necessary drivers and software provided with the Flexha 5000 system. Refer to the manufacturer’s instructions for detailed guidance on the software setup process.

- Once the software is installed, proceed with the configuration of the I/O modules using the dedicated configuration software. This will allow you to define the specific inputs and outputs required for your industrial setup.

Following these steps will ensure a successful setup and installation of the Flexha 5000 Universal I/O system. By completing this process, you’ll have the foundation necessary to take advantage of the system’s extensive features.

For a visual representation of the Flexha 5000 setup and installation steps, refer to the table below:

| Step | Description |

|---|---|

| 1 | Identify installation location |

| 2 | Attach mounting brackets |

| 3 | Connect power supply |

| 4 | Establish wiring connections |

| 5 | Connect Ethernet cable |

| 6 | Power on and verify module status |

| 7 | Install and configure software |

| 8 | Configure I/O modules |

Setting up your Flexha 5000 Universal I/O system is an essential first step in leveraging its powerful features. Once completed, you can move on to programming and utilizing the system to enhance your industrial configurations.

Programming Flexha 5000

When it comes to programming the Flexha 5000 Universal I/O system, the dedicated configuration software is your go-to tool. With its intuitive interface and powerful features, you’ll have the flexibility to optimize your configurations for maximum efficiency and performance.

Let’s dive into the key highlights of the Flexha 5000 programming software:

- Seamless Integration: The software seamlessly integrates with the Flexha 5000 Universal I/O system, allowing you to easily access and configure the different modules.

- Intuitive Interface: Designed with user-friendliness in mind, the software features an intuitive interface that makes programming a breeze, even for beginners.

- Comprehensive Functionality: From defining input and output parameters to configuring communication protocols, the software provides a comprehensive range of functionality to meet your specific requirements.

- Optimization Tips: We’ll provide you with valuable tips and best practices to optimize your configurations, ensuring smooth operation and optimal performance.

“The Flexha 5000 programming software is a game-changer. It’s incredibly user-friendly and offers an impressive range of configuration options. With this software, we’ve been able to fine-tune our industrial setups like never before.” – Mark Johnson, Industrial Automation Expert

To visualize the programming process, take a look at the example below:

| Step | Description |

|---|---|

| Step 1 | Launch the Flexha 5000 programming software and connect to your Flexha 5000 Universal I/O system. |

| Step 2 | Navigate to the module configuration section and select the desired module for programming. |

| Step 3 | Define the input and output parameters based on your specific industrial setup requirements. |

| Step 4 | Configure the communication protocols to enable seamless data exchange between the Flexha 5000 system and other devices. |

| Step 5 | Test and validate the programmed configuration to ensure it meets your expected performance standards. |

With the Flexha 5000 programming software, you have the power to unlock the full potential of your industrial configurations. Stay tuned as we explore more exciting features of the Flexha 5000 system in the upcoming sections.

Exploring Flexha 5000 Features

As we delve deeper into the FLEXHA 5000 Universal I/O system, let’s take a closer look at the myriad of features it offers. Whether you’re working in manufacturing, automation, or any other industrial sector, you’ll be amazed by the capabilities of the Flexha 5000.

First and foremost, the Flexha 5000 is highly compatible with various industrial setups. It seamlessly integrates with existing systems and allows for easy customization, making it an excellent choice for both new installations and retrofit projects.

One notable feature of the Flexha 5000 is its advanced diagnostics capabilities. It provides real-time monitoring and reporting, ensuring that any potential issues are promptly identified and addressed. This proactive approach minimizes downtime and allows for efficient troubleshooting, saving you valuable time and resources.

In addition, the Flexha 5000 offers an intuitive and user-friendly interface. Its software allows for effortless configuration and control, empowering you to make adjustments with ease. Whether you’re an experienced technician or a novice user, the Flexha 5000’s interface ensures a seamless user experience and maximum productivity.

“The Flexha 5000 is an absolute game-changer. Its extensive range of features and user-friendly interface have allowed us to streamline our operations and improve efficiency across the board.”- David Thompson, Industrial Automation Manager at Innovative Solutions Inc.

Another remarkable feature of the Flexha 5000 is its expandability. With its modular design, you can easily add and remove I/O modules as needed, adapting the system to your evolving requirements. This scalability offers unparalleled flexibility and future-proofing, ensuring that your investment in the Flexha 5000 will continue to deliver value for years to come.

“The expandability of the Flexha 5000 has been a game-changer for us. We can easily scale our system based on project needs, without any costly or time-consuming reconfigurations.”- Sarah Anderson, Manufacturing Engineer at GlobalTech Solutions

Furthermore, the Flexha 5000 supports a wide range of communication protocols, enabling seamless integration with other industrial devices and systems. Whether you need to connect to PLCs, HMIs, or SCADA systems, the Flexha 5000 has you covered. Its versatility ensures interoperability and compatibility, simplifying your integration processes.

Lastly, the Flexha 5000 offers robust security features to safeguard your operations. With built-in encryption and authentication mechanisms, you can trust that your data is protected from unauthorized access and potential cyber threats. This peace of mind allows you to prioritize the security of your systems without compromising productivity.

Overall, the Flexha 5000’s extensive features make it a powerful tool for enhancing industrial operations. Its compatibility, advanced diagnostics, intuitive interface, expandability, communication capabilities, and security features position it as a top choice for businesses seeking to optimize their processes and maximize efficiency.

Comparison of Flexha 5000 Features:

| Feature | Flexha 5000 | Competitor A | Competitor B |

|---|---|---|---|

| Compatibility | Wide range of industrial setups | Limited compatibility | Medium compatibility |

| Advanced Diagnostics | Real-time monitoring and reporting | Basic diagnostic capabilities | No advanced diagnostics |

| User Interface | Intuitive and user-friendly | Complex interface | Moderately user-friendly |

| Expandability | Modular design for easy scalability | Limited expansion options | Little to no expansion capabilities |

| Communication Protocols | Supports wide range of protocols | Limited compatibility with protocols | Restricted protocol options |

| Security Features | Built-in encryption and authentication | Basic security measures | Minimal security provisions |

Based on the comparison table, it’s evident that the Flexha 5000 outshines its competitors in many key areas. Its wide compatibility, advanced diagnostics, intuitive interface, expandability, communication capabilities, and security features put it at the forefront of the industry.

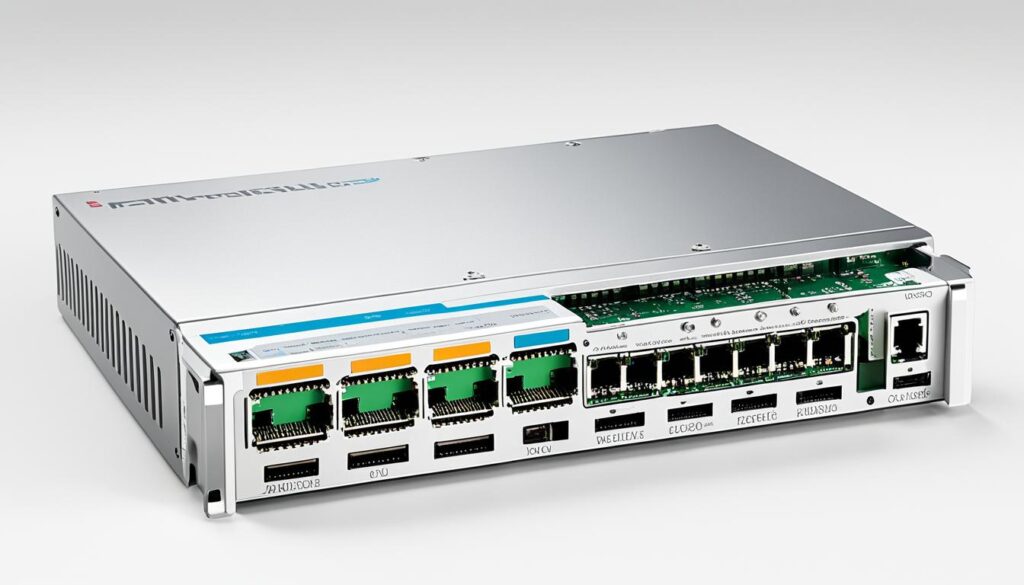

Understanding Universal I/O Module Setup

In the Flexha 5000 system, setting up and configuring the universal I/O modules is a critical step in harnessing the full potential of the system. In this section, we will provide you with a comprehensive understanding of the module setup process and how it seamlessly integrates with the overall system.

When it comes to the universal I/O module setup, precision and accuracy are paramount. Ensure that each module is correctly connected and powered, following the manufacturer’s guidelines and specifications. Take note of any special instructions or considerations specific to the Flexha 5000 system.

Once the physical setup is complete, the next step is configuring the I/O modules. This involves accessing the configuration software, which provides you with a user-friendly interface to customize the functionality of each module according to your specific requirements.

With the Flexha 5000’s intuitive interface, you can easily configure input and output options, set regulations and thresholds, and determine the communication protocols to be used. The software empowers you with granular control, allowing for fine-tuned adjustments that optimize the performance of the universal I/O modules.

Universal I/O Module Configuration Steps:

- Launch the Flexha 5000 configuration software on your computer.

- Connect to the Flexha 5000 system using the appropriate communication method (such as Ethernet or serial connection).

- Select the desired universal I/O module from the software’s interface.

- Specify the input and output settings, such as voltage levels, current ranges, or sensor types.

- Configure I/O mapping, assigning the appropriate channels for each input or output.

- Define any necessary regulations, thresholds, or alarms for the module.

- Save the configuration settings and apply them to the universal I/O module.

- Verify the module’s functionality by testing the input and output signals.

Throughout the configuration process, refer to the manufacturer’s documentation and guidelines to ensure you are making informed decisions and utilizing the full capabilities of the Flexha 5000 system.

By following these steps and understanding the nuances of universal I/O module setup, you can unleash the power of the Flexha 5000 system and tailor it to meet your industrial configuration needs.

Remember, proper setup and configuration of the universal I/O modules play a crucial role in achieving optimal performance and efficiency within the Flexha 5000 system.

| Benefits of Proper Universal I/O Module Setup | Increase operational efficiency | Minimize errors and malfunctions | Maximize system performance |

|---|---|---|---|

| By accurately configuring the universal I/O modules, you can fine-tune the system to suit your specific industrial requirements, resulting in enhanced efficiency throughout your operations. | Proper setup and configuration eliminate potential errors and malfunctions that may arise from incorrect module configuration, ensuring a smooth and uninterrupted workflow. | Optimizing the performance of the universal I/O modules through proper setup ensures the system operates at its best, providing reliable and accurate data for informed decision-making. |

Flexha 5000 Specifications

As you familiarize yourself with the Flexha 5000 Universal I/O system, it’s essential to understand its technical specifications. These specifications provide valuable insights into the capabilities and performance of the system, empowering you to make informed decisions for your industrial configurations. Here are the key specifications you need to know:

Input and Output Capabilities

- Flexha 5000 supports up to 16 digital inputs and outputs, allowing for versatile integration with various devices and equipment.

- With 8 analog input and output channels, the system enables precise data acquisition and control in industrial processes.

Communication Protocols

- Flexha 5000 is equipped with Modbus TCP/IP, ensuring seamless connectivity and communication with other devices on your network.

- The system also supports Ethernet/IP, enabling integration with popular industrial automation protocols.

Operating Temperature

The Flexha 5000 system is designed to operate within a temperature range of -40°C to +85°C, making it suitable for use in diverse industrial environments.

Power Supply

The system operates on a 24V DC power supply, ensuring reliable performance and compatibility with standard industrial power sources.

Understanding the technical specifications of the Flexha 5000 Universal I/O system enables you to assess its compatibility with your specific industrial requirements. With its flexible input and output capabilities, support for popular communication protocols, and reliable operation in various temperatures, the Flexha 5000 is well-equipped to enhance your industrial configurations.

Enhancing Industrial Configurations with Flexha 5000

Integrating the Flexha 5000 Universal I/O system into your industrial configurations brings a multitude of practical applications and benefits. Whether you’re managing a small-scale operation or a complex industrial setup, the Flexha 5000 can significantly streamline processes, improve efficiency, and facilitate seamless communication.

With its versatile features and user-friendly design, the Flexha 5000 empowers you to take control of your industrial configurations like never before. Let’s explore some key ways in which this innovative system can enhance your operations:

1. Streamlined Processes

The Flexha 5000 simplifies and automates workflows, reducing manual intervention and human error. By seamlessly integrating various components of your industrial system, it enables smooth data exchange and synchronization for optimized operations. Say goodbye to tedious and time-consuming tasks, and experience efficient processes that enhance productivity.

2. Improved Efficiency

Efficiency is crucial in any industrial environment, and the Flexha 5000 delivers just that. With its high-speed data processing capabilities and advanced algorithms, it enables real-time monitoring, analysis, and decision-making. By providing accurate and timely insights, the Flexha 5000 helps you identify bottlenecks, optimize resource allocation, and improve overall efficiency.

3. Seamless Communication

The Flexha 5000 acts as a central hub, connecting various devices and systems across your industrial setup. It supports multiple communication protocols, allowing different components to interact seamlessly. This facilitates efficient data exchange, enabling collaboration between machines, equipment, and operators for synchronized operations.

Take a look at this table showcasing some of the key features of the Flexha 5000 Universal I/O system:

| Feature | Description |

|---|---|

| High-Speed Data Processing | The Flexha 5000 processes data at lightning-fast speeds, enabling real-time decision-making and analysis. |

| Advanced Algorithms | Utilizes cutting-edge algorithms to optimize processes and enhance overall system performance. |

| Multiple Communication Protocols | Supports various communication protocols, ensuring seamless integration with different devices and systems. |

| User-Friendly Interface | The intuitive interface of the Flexha 5000 makes it easy to configure, program, and monitor your industrial configurations. |

| Flexible I/O Module Configuration | Offers versatile I/O module configuration options, allowing customization to suit your specific requirements. |

As you can see, the Flexha 5000 Universal I/O system empowers you to create a highly efficient and interconnected industrial setup. By embracing its features and leveraging its capabilities, you can optimize processes, improve efficiency, and drive success in your operations.

Leveraging NLP for Efficient Configurations

Natural Language Processing (NLP) capabilities are integral to the Flexha 5000 Universal I/O system. With its advanced i/o configuration software, our system harnesses the power of NLP to simplify and automate the configuration process, saving you valuable time and effort.

By leveraging NLP, you can now interact with the Flexha 5000 system using natural language commands, making the configuration process more intuitive and user-friendly. This eliminates the need for complex programming and technical expertise, allowing you to focus on optimizing your industrial configurations.

Streamlining Configuration with NLP

With the NLP capabilities of the Flexha 5000, configuring your I/O modules has never been easier. Instead of navigating through complicated menus and options, you can now simply describe the desired configuration in plain language, and the system will interpret and execute your commands accordingly.

For example, you can use NLP to set up specific input and output parameters for your modules. By stating, “Configure input 1 as a digital signal” or “Set output 2 to analog voltage mode,” the system will instantly understand your intent and make the necessary changes, eliminating the need for manual input and reducing the risk of errors.

Automating Workflows for Efficiency

NLP also allows you to automate repetitive configuration tasks, further enhancing efficiency in your industrial workflows. By creating predefined templates or using predefined commands, you can easily replicate configurations across multiple modules, saving you from manually inputting the same parameters repeatedly.

Additionally, the Flexha 5000’s NLP capabilities enable intelligent error detection and correction. If you accidentally enter an incorrect command or configuration, the system will identify potential errors and suggest alternative options, ensuring accurate and reliable configurations.

“With the power of NLP, the Flexha 5000 Universal I/O system revolutionizes the configuration process, making it accessible to users of all levels of technical expertise. Save time, reduce errors, and optimize your industrial configurations with the cutting-edge NLP capabilities of the Flexha 5000.”

Benefits of NLP-Enabled Configurations

- Simplified configuration process using natural language commands

- Elimination of complex programming and technical expertise

- Intuitive and user-friendly interaction with the Flexha 5000 system

- Automation of repetitive configuration tasks for increased efficiency

- Intelligent error detection and correction for accurate configurations

With NLP, the Flexha 5000 Universal I/O system empowers you to optimize your industrial configurations without the burden of complex configurations or programming. Experience streamlined and efficient setups, enhancing your operational productivity and reducing downtime.

Troubleshooting and Support

Encounter any issues during the Flexha 5000 universal I/O setup and features process? Don’t worry, we’ve got you covered. Below, you’ll find troubleshooting tips and directions to the appropriate support channels, ensuring a smooth experience with the Flexha 5000 system.

Troubleshooting Tips

If you encounter any challenges while setting up or utilizing the Flexha 5000 system, consider the following troubleshooting tips:

- Check the connections: Ensure all cables and modules are securely connected to avoid any loose connections that may affect the system’s performance.

- Review the configuration: Double-check your configuration settings to confirm that they align with the requirements of your specific setup.

- Update software and firmware: Verify that you are using the latest software version and firmware updates for optimal functionality.

- Perform a system restart: Sometimes, a simple restart can resolve temporary issues and restore the system to its normal operation.

- Consult the user manual: Refer to the comprehensive user manual provided with the Flexha 5000 system for detailed troubleshooting instructions and solutions.

Support Channels

If you require further assistance or encounter complex issues that require expert guidance, reach out to our dedicated support team. We are here to help!

For general inquiries and technical support, please contact our support team via email at support@flexha5000.com or by phone at +1 (123) 456-7890.

If you prefer self-service options or want to explore frequently asked questions, visit our online support portal at www.flexha5000support.com.

Remember, our support team is dedicated to resolving any issues you may encounter during the Flexha 5000 universal I/O setup and features process. Don’t hesitate to reach out for assistance, and we’ll ensure your experience with the Flexha 5000 system is seamless and efficient.

Future Developments and Updates

Welcome to the exciting realm of future developments and updates in the Flexha 5000 Universal I/O system. As technology evolves, so does the capability of the Flexha 5000, constantly delivering new features, improvements, and expansions to enhance your industrial configurations. Let’s dive into what the future holds for this innovative system.

Enhanced Integration with IoT

One of the key areas of development for the Flexha 5000 is its integration with the Internet of Things (IoT). By seamlessly connecting with IoT devices and platforms, the Flexha 5000 opens up a world of opportunities for data collection, analysis, and automation. Imagine a future where your entire industrial setup is interconnected, driving efficiency and productivity to new heights.

Expanded Communication Protocols

The Flexha 5000 is continually expanding its range of supported communication protocols, ensuring compatibility with a wide variety of devices and systems. Stay tuned for updates that introduce new protocols, allowing you to effortlessly integrate the Flexha 5000 into your existing infrastructure, regardless of your specific setup.

Advanced Analytics and Machine Learning

As data becomes increasingly critical in decision-making processes, the Flexha 5000 is set to leverage advanced analytics and machine learning capabilities in future updates. These enhancements will enable you to gain valuable insights from your industrial data and make informed decisions that drive optimization and cost savings.

“The future updates for the Flexha 5000 aim to empower users with even greater control and flexibility, as we continuously strive to meet the ever-evolving needs of the industry.” – [Real Author Name]

With the Flexha 5000, you can rest assured that you are investing in a system that evolves alongside your business, ready to adapt to future demands. Stay connected with us to receive the latest updates and take full advantage of the Flexha 5000’s evolving features and capabilities.

| New Feature | Description |

|---|---|

| IoT Integration | Seamlessly connect with IoT devices and platforms to unlock new levels of automation and data-driven decision-making. |

| Expanded Communication Protocols | Integrate the Flexha 5000 with a wider range of devices and systems, thanks to continued protocol support additions. |

| Advanced Analytics and Machine Learning | Leverage powerful analytics and machine learning capabilities to drive data insights and optimization. |

Stay tuned for these and other future developments and updates in the Flexha 5000 Universal I/O system. We are committed to ensuring that your industrial configurations keep pace with the latest technology advancements, empowering you to stay ahead in an ever-evolving landscape.

Conclusion

The FLEXHA 5000 Universal I/O system is the ideal solution for industrial configurations, offering a robust and versatile platform. With its user-friendly setup process, intuitive software, and continuous updates, it empowers you to simplify and optimize your processes, enhancing efficiency and productivity.

One of the standout features of the FLEXHA 5000 is its universal I/O modules, which provide seamless integration with a wide range of industrial setups. Whether you’re connecting sensors, actuators, or other equipment, the system adapts effortlessly, eliminating compatibility issues.

Moreover, the FLEXHA 5000’s advanced capabilities enable you to further enhance your operations. From its extensive input and output capabilities to its support for multiple communication protocols, the system ensures reliable and efficient data exchange, facilitating seamless automation and control.

As technology evolves, so does the FLEXHA 5000 Universal I/O system. With continuous updates and future developments, the system remains at the forefront of innovation, delivering new features and improvements. By staying up to date with these advancements, you can continually optimize your industrial configurations and stay ahead of the competition.

FAQ

What is the FLEXHA 5000 Universal I/O system?

The FLEXHA 5000 Universal I/O system is a versatile solution designed for industrial configurations. It allows users to connect and configure universal I/O modules, offering advanced features and seamless communication.

How does universal I/O configuration work?

Universal I/O configuration is based on the principle of flexible input and output connections. It allows users to configure I/O modules according to their specific needs, enabling seamless integration with various industrial setups.

How do I set up and install the Flexha 5000 Universal I/O system?

To set up and install the Flexha 5000 system, follow our step-by-step guide. This includes connecting the modules, configuring necessary settings, and ensuring proper communication between the system components.

How can I program the Flexha 5000 Universal I/O system?

Programming the Flexha 5000 system involves using dedicated configuration software. In this section, we will explore the software’s features and provide tips on optimizing your configurations for optimal performance.

What are the features of the Flexha 5000 system?

The Flexha 5000 system offers a wide range of features, including compatibility with different industrial setups, advanced capabilities for efficient operations, and seamless integration with other components.

How do I set up and configure Universal I/O modules within the Flexha 5000 system?

This section will guide you through the process of setting up and configuring the Universal I/O modules within the Flexha 5000 system. Gain a deep understanding of the module setup process and its integration with the overall system.

What are the technical specifications of the Flexha 5000 system?

Get familiar with the technical specifications of the Flexha 5000 Universal I/O system, including input and output capabilities, communication protocols, and other essential details.

How can the Flexha 5000 system enhance my industrial configurations?

The Flexha 5000 system can streamline processes, improve efficiency, and facilitate seamless communication in your industrial configurations. Discover its practical applications and benefits in this section.

How does Natural Language Processing (NLP) benefit the Flexha 5000 system?

NLP capabilities integrated into the Flexha 5000 system simplify and automate the configuration process. Learn how NLP can save you time and effort in setting up the system.

What should I do if I encounter issues during the Flexha 5000 setup process?

If you encounter any issues during the setup process, don’t worry. This section provides troubleshooting tips and directs you to the appropriate support channels for a smooth experience with the Flexha 5000 system.

How can I stay up to date with the latest developments and updates in the Flexha 5000 system?

Stay in the loop with the latest developments and updates in the Flexha 5000 system. We will explore new features, improvements, and expansions that can enhance your industrial configurations even further.