Welcome to our comprehensive guide to the inspection and testing of medium-voltage (MV) metal-clad switchgear. As a professional copywriting journalist, we know that regular inspection and testing are critical to ensuring the reliable and safe operation of electrical equipment. In this section, we will provide a detailed overview of the inspection and testing process, discussing its importance and the benefits it brings to the overall safety and efficiency of electrical equipment.

Our expert guide will cover the key steps involved in inspecting and testing MV metal-clad switchgear, including the specific techniques and testing procedures to follow. We will also explain the importance of regular maintenance and safety testing, highlighting the significance of periodic activities such as cleaning, lubrication, and tightening of connections.

With this guide, you will gain valuable insights into the inspection and testing of MV metal-clad switchgear, allowing you to ensure the longevity and safe operation of your electrical equipment.

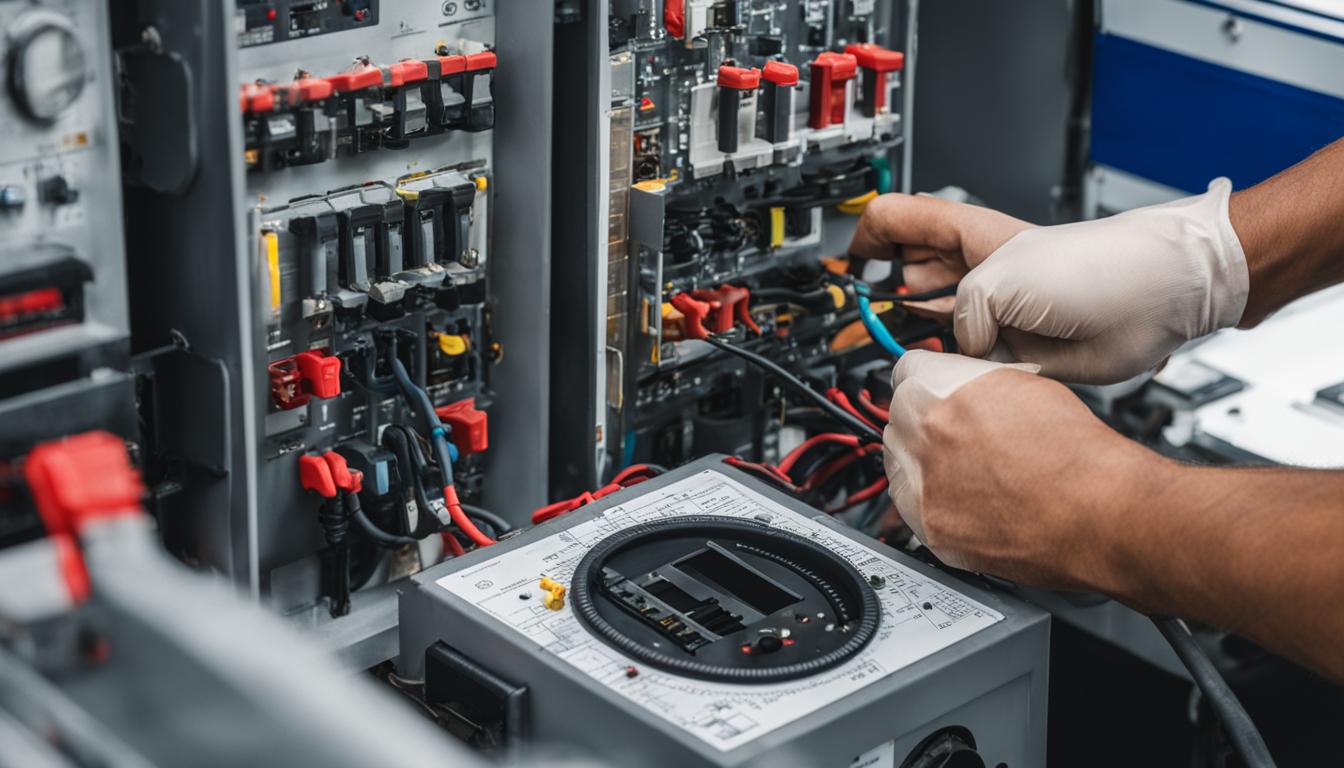

A close-up of a gloved hand holding a multimeter while testing the voltage of a metal-clad switchgear panel. The panel is opened, and the interior components are visible behind a safety grill. In the background, an electrician wearing protective gear is observing the testing process.

Key Takeaways:

- Regular inspection and testing are critical to ensuring reliable and safe operation of MV metal-clad switchgear

- Inspection techniques include visual inspection, thermal imaging, and electrical testing methods

- Testing procedures include insulation resistance testing, circuit breaker testing, and contact resistance measurement, among others

- Regular maintenance activities such as cleaning, lubrication, and tightening of connections are crucial to ensure the longevity and safety of electrical equipment

- Proper documentation and record-keeping are essential for future reference and compliance with industry regulations

Understanding MV Metal-clad Switchgear

Before we dive into the inspection and testing procedures, let’s first understand the basics of medium-voltage (MV) metal-clad switchgear. Switchgear refers to the combination of electrical disconnect switches, fuses or circuit breakers used to control, protect, and isolate electrical equipment.

MV metal-clad switchgear is commonly used in high-voltage applications, typically from 5kV to 38kV. The metal-clad construction means that the equipment is enclosed in a grounded metal compartment, providing added protection against electrical faults and ensuring safety for maintenance personnel.

Proper inspection and testing of MV metal-clad switchgear is essential to ensure its reliable operation. A thorough inspection and testing process can identify potential issues before they turn into major problems, preventing costly downtime and equipment failure.

There are various types of switchgear, including air-insulated switchgear (AIS), gas-insulated switchgear (GIS), and hybrid switchgear. AIS is the most common type of switchgear and is typically used for low-voltage applications. GIS is used for higher voltage levels and has a smaller footprint, making it suitable for urban areas. Hybrid switchgear combines features of AIS and GIS to optimize performance and minimize cost.

Faulty switchgear can pose significant risks, including electrical shocks, fires, and explosions. Regular maintenance and inspection can help detect potential issues and mitigate these risks. High voltage switchgear testing and medium voltage switchgear inspection are critical to ensuring the safety and reliability of electrical equipment.

“A thorough inspection and testing process can identify potential issues before they turn into major problems, preventing costly downtime and equipment failure.”

Inspection Techniques for MV Metal-clad Switchgear

Ensuring the reliable operation of medium-voltage (MV) metal-clad switchgear requires thorough inspection techniques. In this section, we will explore the specific methods used for inspecting metal-clad switchgear to identify potential issues and ensure their safe and efficient operation.

Visual Inspection

Visual inspection is the first and most critical step in the inspection process. It involves a comprehensive examination of the entire MV metal-clad switchgear to identify any signs of damage, wear and tear, or other anomalies. During the visual inspection, we typically look for:

- Corrosion or rust on the metal parts of the switchgear

- Loose connections or signs of overheating

- Cracks or other damages to the enclosure or insulators

These visual checks can provide valuable insight into the condition of the switchgear, helping to identify potential hazards and prevent further damage.

Thermal Imaging

Thermal imaging is another critical inspection technique used to identify hotspots and other temperature-related anomalies that may indicate underlying issues with the switchgear. This technique involves the use of an infrared camera to detect temperature variations across the switchgear, which can highlight potential hazards such as overheating or loose connections.

By using thermal imaging, we can identify issues that may not be visible to the naked eye, ensuring that any potential problems are identified and addressed before they cause significant damage to the switchgear.

Electrical Testing Methods

Electrical testing is a critical aspect of the inspection process, helping to identify potential safety hazards and ensure the reliable operation of the switchgear. Several electrical testing methods can be used to test the MV metal-clad switchgear, including:

| Test Type | Purpose |

|---|---|

| Insulation resistance testing | To identify any insulation issues |

| Circuit breaker testing | To ensure proper operation and identify any wear and tear or damage to the circuit breaker |

| Contact resistance measurement | To measure the resistance of the switchgear contacts and identify any potential issues |

Using these electrical testing methods can help to identify any potential issues with the MV metal-clad switchgear, ensuring that it is safe and efficient to operate.

In the next section, we will outline the specific testing procedures that should be conducted to ensure the reliable operation of the MV metal-clad switchgear.

Testing Procedures for MV Metal-clad Switchgear

After completing the inspection process, the next step is to conduct thorough testing of the MV metal-clad switchgear to ensure its optimal performance. There are various types of tests involved in this process, each serving a specific purpose in assessing the system’s functionality.

Insulation Resistance Testing

The insulation resistance test is conducted to measure the resistance of the insulation materials in the switchgear. This test helps determine the overall condition of the insulation system and identify any potential issues that may cause a fault. The test involves applying a high voltage between the conductors and the ground, and measuring the current flowing through the insulation.

Circuit Breaker Testing

The circuit breaker is an essential component of MV metal-clad switchgear, and its proper functionality is crucial for the overall performance of the system. The circuit breaker testing involves measuring the timing and operation of the circuit breaker mechanism, assessing its ability to interrupt the current and handle the fault levels. This type of testing prevents unexpected shutdowns and reduces the risk of equipment damage.

Contact Resistance Measurement

The contact resistance measurement test helps identify any contact issues in the switchgear, such as loose connections or corroded contacts. This test involves measuring the resistance between the different contact points in the system, and any readings outside of the acceptable range indicate a problem that needs addressing.

Other Tests

There are various other tests that can be conducted to assess the overall performance of the MV metal-clad switchgear, including power factor testing, HV testing, and partial discharge testing. Each of these tests is designed to measure different aspects of the switchgear’s operation and identify potential issues that may affect its performance.

Show a technician using a megohmmeter to test the insulation resistance of the busbars in an MV metal-clad switchgear.

Proper testing procedures are essential to ensure the reliability and safety of the MV metal-clad switchgear. It is recommended to perform testing at least once a year or whenever significant changes are made to the system. The test results should be documented and recorded for future reference, enabling easy tracking of any changes and issues that may have arisen over time.

Importance of Regular Maintenance and Safety Testing

Regular maintenance and safety testing are vital for ensuring the reliability and safety of MV metal-clad switchgear. Proper maintenance activities, such as cleaning, lubrication, and tightening of connections, can prevent potential failures and prolong the lifespan of the switchgear system. Electrical safety testing is also crucial to identify potential hazards and ensure compliance with industry regulations.

At our company, we take pride in offering comprehensive electrical maintenance services, including switchgear maintenance and safety testing. Our experienced technicians follow industry-standard procedures to ensure that your electrical equipment is operating safely and efficiently.

Our switchgear maintenance services include visual inspection, cleaning, lubrication, and tightening of connections. We use specialized equipment to measure contact resistance and insulation resistance, ensuring that the switchgear is operating within the recommended limits. Our technicians also conduct circuit breaker testing and other electrical tests as required.

In addition to regular maintenance, we also offer electrical safety testing services to identify potential hazards and ensure compliance with industry regulations. Our testing services include ground resistance testing, insulation resistance testing, and high potential testing, among others.

Benefits of Regular Maintenance and Safety Testing

The benefits of regular maintenance and safety testing are multifaceted. Proper maintenance and testing activities can:

- Prevent equipment failures and reduce downtime

- Ensure compliance with industry standards and regulations

- Extend the lifespan of switchgear and other electrical equipment

- Improve the efficiency and performance of equipment

- Identify potential safety hazards and prevent accidents

By investing in regular maintenance and safety testing services, you can ensure the safe and efficient operation of your electrical equipment. Contact our company today to learn more about our comprehensive maintenance and testing services.

Switchgear Condition Assessment and Maintenance Checklist

Regular maintenance and inspection of MV metal-clad switchgear are crucial to ensure safe and efficient operation. As discussed in previous sections, various types of inspection and testing must be conducted periodically to identify any potential issues and mitigate risks. To streamline the process, having a comprehensive checklist and conducting a condition assessment can be helpful.

The following is a sample maintenance checklist that can be customized based on the specific requirements:

| Checklist Item | Check Frequency | Comments |

|---|---|---|

| Visual inspection of switchgear | Monthly | |

| Thermal imaging of switchgear | Annually | |

| Insulation resistance testing | Every 3 years | |

| Circuit breaker testing | Every 2 years | |

| Contact resistance measurement | Every 5 years | |

| Cleaning, lubrication, and tightening of connections | Quarterly | |

| Electrical safety testing | Every 2 years |

The switchgear condition assessment should include a thorough visual inspection of every component, identification of any visible damage, and an inspection of the mechanical and electrical operations of the device. The assessment should also include checking the oil level of the transformer (if applicable) and the insulation resistance of the circuit breaker. Any issues identified during the inspections and tests should be documented, and necessary repairs or corrective actions should be taken promptly.

“By following a comprehensive maintenance checklist and conducting regular condition assessments, we can ensure the safe and efficient operation of MV metal-clad switchgear, minimize downtime, and extend the life of our electrical equipment.”

Conclusion

In conclusion, we hope this expert guide has provided a comprehensive understanding of the inspection and testing process of MV metal-clad switchgear. It is essential to conduct regular inspections and testing to ensure the safety and efficiency of electrical equipment.

With proper maintenance and testing procedures in place, you can identify potential issues before they escalate, minimize downtime, and extend the lifespan of your switchgear system. Remember to follow industry regulations and document all inspection and testing results for future reference.

Thank you for reading, and we hope you found this guide informative and helpful. Don’t hesitate to contact us if you have any further questions.

FAQ

Why is regular inspection and testing of MV metal-clad switchgear important?

Regular inspection and testing of MV metal-clad switchgear is important because it ensures the overall safety and efficiency of electrical equipment. It helps identify potential issues, minimize downtime, and prolong the lifespan of the switchgear system.

What is MV metal-clad switchgear?

MV metal-clad switchgear is a type of electrical distribution equipment that is used to control and protect electrical power systems with medium voltage levels. It consists of circuit breakers, disconnect switches, and other components housed in a metal enclosure.

What are the risks associated with faulty switchgear?

Faulty switchgear can pose significant risks, including electrical failures, power outages, equipment damage, and even electrical hazards such as fires and explosions. Proper inspection and testing help mitigate these risks by identifying and addressing any potential faults or issues.

What are the inspection techniques used for MV metal-clad switchgear?

The inspection techniques used for MV metal-clad switchgear include visual inspection, thermal imaging, and electrical testing methods. These techniques help assess the condition of the switchgear components, detect any abnormalities, and ensure their proper functioning.

What testing procedures are involved in MV metal-clad switchgear?

Testing procedures for MV metal-clad switchgear include insulation resistance testing, circuit breaker testing, contact resistance measurement, and others. These tests help evaluate the performance and reliability of the switchgear components and ensure their compliance with industry standards.

Why is regular maintenance and safety testing important for switchgear?

Regular maintenance and safety testing are important for switchgear to ensure its reliable operation and the safety of personnel. Maintenance activities such as cleaning, lubrication, and tightening of connections help prevent issues and extend the lifespan of the switchgear. Safety testing helps identify potential hazards and ensures compliance with industry regulations.

What is a switchgear condition assessment and why is it necessary?

A switchgear condition assessment involves evaluating the overall condition and performance of the switchgear system. It helps identify any potential issues or faults and provides insights for necessary maintenance or repairs. Conducting a condition assessment and keeping a maintenance checklist streamline the inspection and testing process.

What is the importance of documentation and record-keeping in switchgear maintenance?

Documentation and record-keeping are crucial in switchgear maintenance as they provide a reference for previous inspections, tests, and maintenance activities. They help track the history of the switchgear, identify recurring issues, and maintain a comprehensive record for future reference or compliance purposes.