Introduction to Schneider Electric Altivar Soft Starters

Schneider Electric, a global leader in energy management and automation solutions, has developed a range of Altivar soft starters that redefine motor control technology for modern industrial applications. Among these offerings, the ATS430 and ATS490 stand out as advanced soft starter models that serve diverse industrial segments with tailored features, capabilities, and power ranges.

Soft starters are crucial devices that allow electric motors to start and stop smoothly by controlling voltage or torque during startup and shutdown phases. This technology effectively reduces mechanical and electrical stress, extends equipment life, and optimizes energy usage compared to traditional full-voltage direct-on-line starting methods.

The Altivar ATS430 and ATS490 both embrace Schneider Electric’s innovative technologies, including torque control, condition monitoring, integrated bypass relays for high efficiency, and robust connectivity options. Despite their shared fundamentals, these two models are designed with distinct target applications, power ranges, and feature sets, offering users a choice optimized for their specific industrial needs.

Fundamental Technology and Design Principles

Advanced Torque Control Technology

Both the ATS430 and ATS490 models utilize Schneider Electric’s proprietary torque control technology, which is a more precise and sophisticated approach than traditional voltage reduction. Instead of merely limiting voltage, torque control directly manages the motor’s torque output during starting and stopping phases. This results in:

- Reduced mechanical wear and tear through smoother acceleration and deceleration.

- Minimized electrical stress and current surges during motor startup.

- Enhanced process control, especially in applications requiring precise torque measurement.

In the ATS490, this torque control is further enhanced to advanced torque control, facilitating better handling of heavy-duty and high-inertia loads often found in process manufacturing and infrastructure environments.

Electrical Power and Voltage Ratings

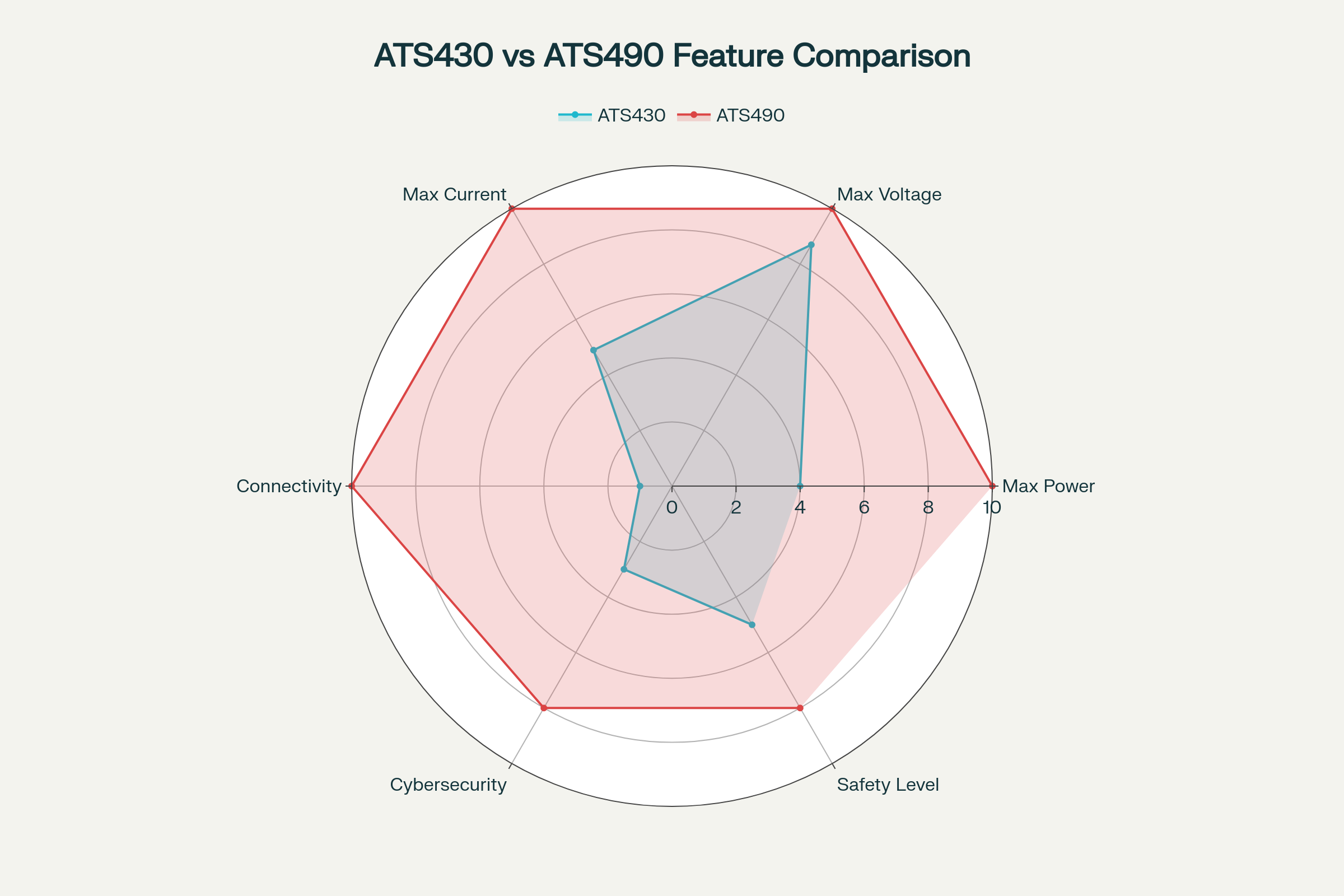

The power handling capabilities mark a key differentiating factor between the ATS430 and ATS490:

- ATS430: Supports motors from 4kW up to 400kW (approximately 3 HP to 500 HP). It functions efficiently in 208 to 600V AC networks and can handle currents in the range of 17 to 590 amps. Its technical range matches typical requirements in discrete manufacturing and light industrial machines.

- ATS490: Designed for more demanding operations, it supports motors from 4kW up to 900kW (3 HP to 1200 HP) with voltage ranges extending up to 690V AC and current capacity up to 1200 amps. This range suits heavy process industries like mining, water treatment, and large HVAC systems.

The ATS490’s capacity to handle larger motors and higher voltages makes it indispensable in infrastructures requiring robust and scalable motor control.

Efficiency and Bypass Integration

Both models integrate internal bypass relays that significantly improve operational efficiency by bypassing the starter after the motor reaches nominal speed. This feature achieves an outstanding efficiency rating of approximately 99.5%, reducing heat losses and improving energy conservation.

The internal bypass eliminates the need for external contactors, simplifying wiring and reducing costs while maintaining optimum motor protection.

Application Focus and Industry Deployment

ATS430: The Workhorse for Discrete Manufacturing and Standard Industrial Applications

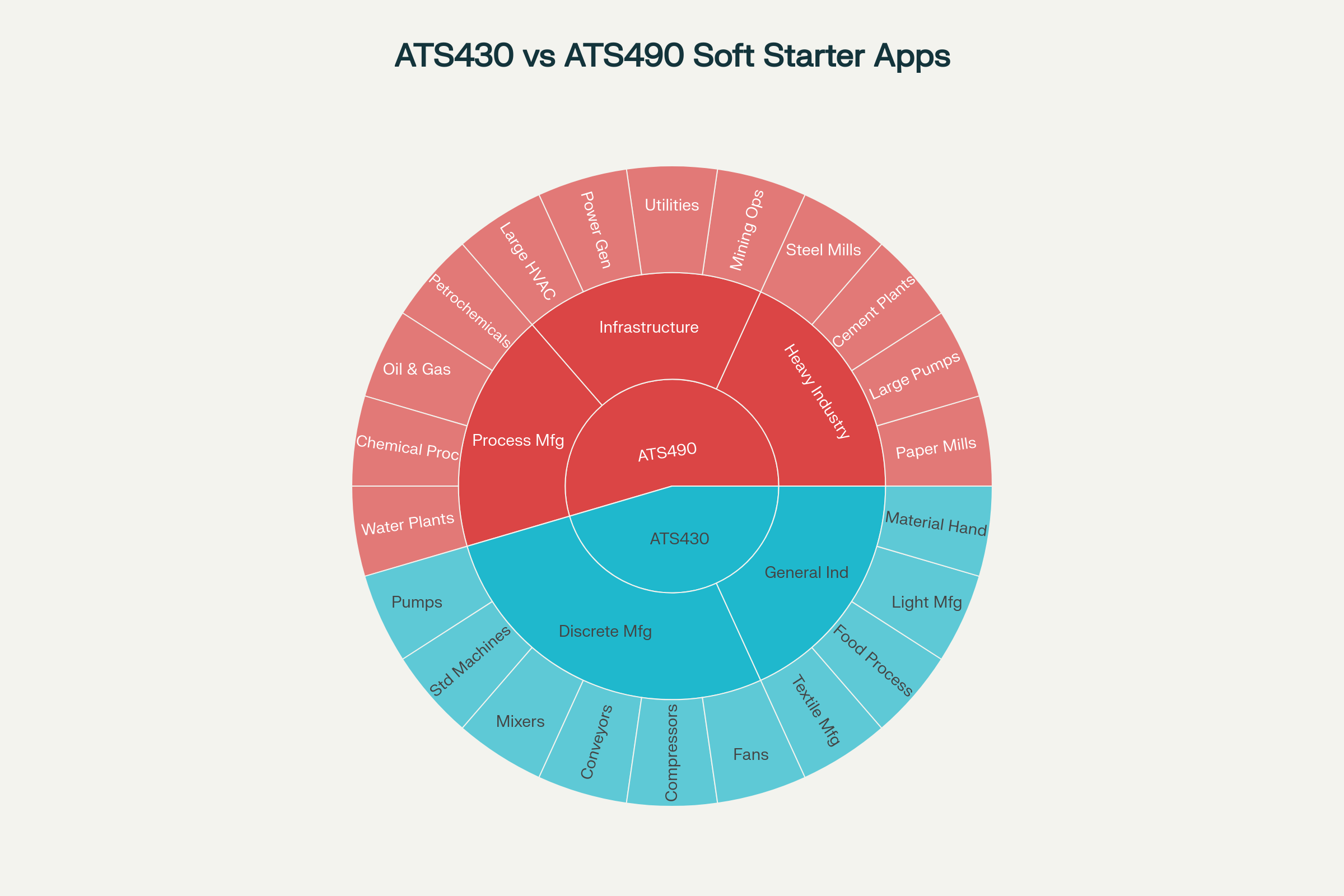

The ATS430 is optimized for industries with moderate power demands and relatively straightforward motor control needs. It targets:

- Discrete Manufacturing: Including assembly lines, packaging machines, conveyors, mixers, and material handling equipment.

- Pumps and Fans: Common in water processing plants, HVAC systems, and light industrial operations.

- Compressors and Mixers: Where gentle motor starts prevent process upset and mechanical stress.

Industries deploying ATS430 often require reliable soft starters that balance advanced control features and cost-effectiveness. The ATS430 enables these operations to reduce motor wear and power spikes without the complexity or cost of more premium systems.

ATS490: Premium Performance for Process Industries and Large Infrastructure

The ATS490 is engineered with features designed exclusively for complex and critical applications, including:

- Water and Wastewater Treatment: Large motor pumps, aeration blowers, and chemical dosing pumps.

- Mining Operations: Conveyor belts, crushers, and heavy-duty ventilation fans that demand rugged and reliable motor control.

- Industrial HVAC: Cooling towers, large axial fans, chillers requiring precise and reliable motor starts.

- Process Manufacturing: Chemical, petrochemical, oil and gas, pulp and paper industries with high horsepower motors and safety requirements.

The ATS490 provides the robustness, scalability, and enhanced monitoring that these sectors demand to ensure maximum uptime, efficiency, and safety.

Control and Connectivity Features

Communication Protocols

Connectivity is essential for industrial smart devices integrating into modern automated environments:

- ATS430: Supports Modbus RTU, a widely used serial communication protocol. This suits many general industrial applications and enables basic integration with PLCs and SCADA systems.

- ATS490: Supports a wide array of industrial network protocols, including Modbus RTU and TCP, EtherNet/IP, PROFINET, PROFIBUS DP, and CANopen. This extensive support suite enables deep integration in distributed control systems and modern Industry 4.0 environments.

This diverse connectivity versatility makes the ATS490 fit for complex automation networks with remote monitoring, diagnostics, and control over Ethernet or fieldbus networks.

Cybersecurity

In the age of connected devices, cybersecurity is critical:

- ATS430: Implements basic cybersecurity best practices, such as Role-Based Access Control (RBAC) and PIN code protection to prevent unauthorized access.

- ATS490: Complies with IEC 62443-4-2 Security Level 1 (SL1) certifications, providing robust protection against cyber-attacks, including secure communication, authentication, and encrypted data transfer.

This advanced cybersecurity compliance in the ATS490 makes it suitable for critical infrastructure installations requiring stringent operational security.

Safety and Motor Protection

Safe Torque Off (STO) and Safety Standards

The ATS490 incorporates an important safety feature called Safe Torque Off (STO), certified to SIL1 (Safety Integrity Level 1) according to IEC 61508 standards, which:

- Enables the device to safely disconnect power to the motor without using external contactors.

- Simplifies safety circuits and reduces system complexity.

- Ensures quick and reliable motor shutdown in emergency scenarios.

While the ATS430 offers basic condition monitoring and motor protection features, the STO safety function is exclusive to the ATS490, underscoring its role in high-demand environments where functional safety is mandated.

Condition Monitoring and Predictive Maintenance

Both soft starters provide condition monitoring, but at different scales:

- ATS430: Monitors internal parameters like device temperature, operating hours, and current levels. This facilitates basic predictive maintenance and cleaning schedules.

- ATS490: Extends condition monitoring to include the motor and driven equipment. It uses sophisticated analytics to detect abnormal vibrations, thermal conditions, and mechanical wear patterns, providing early alerts to maintenance teams.

These predictive capabilities enable optimization of maintenance programs, reduce unplanned downtime, and extend equipment longevity.

Installation and Integration Considerations

Physical Installation and Environment

Both ATS430 and ATS490 are designed for ease of installation in industrial electrical panels:

- Compact form factors with DIN rail mounting or panel mounting options.

- Environmental ratings are typically IP20, with additional protection kits for harsher settings.

- Wiring configurations supporting three-phase power with 110-230V control supply.

- Compliance with global electrical standards facilitates worldwide deployment.

The ATS490 may require additional considerations for environmental sealing and network security configurations during installation due to its advanced features and networking capabilities.

Configuration and Parameterization

Configuration for both models leverages Schneider Electric’s EcoStruxure Control Expert or built-in interfaces, supporting:

- Motor parameters entry (current, voltage, power rating).

- Start and stop ramp settings for acceleration and deceleration.

- Current limit settings and protection parameters.

- Connectivity and communication setup.

The ATS490 delivers additional advanced configuration options to tailor device behavior for complex process needs, including multi-motor control scenarios and dynamic braking setups.

Comparative Summary of Key Specifications and Features

| Feature | ATS430 | ATS490 |

|---|---|---|

| Power Range | 4 – 400 kW (3 – 500 HP) | 4 – 900 kW (3 – 1200 HP) |

| Voltage Range | 208 – 600 V AC | 208 – 690 V AC |

| Current Range | 17 – 590 A | 17 – 1200 A |

| Control Type | Torque Control | Advanced Torque Control |

| Target Industries | Discrete manufacturing, pumps, fans, conveyors | Process manufacturing, mining, water treatment, infrastructure |

| Efficiency | 99.5% | 99.5% |

| Safety Features | Condition monitoring | Condition monitoring + Safe Torque Off (SIL1) |

| Connectivity | Modbus RTU | Modbus RTU, Modbus TCP, EtherNet/IP, PROFIBUS, PROFINET, CANopen |

| Cybersecurity | Basic best practices | IEC 62443-4-2 SL1 certified |

| Bypass Relays | Integrated for efficiency | Integrated for efficiency |

| Condition Monitoring | Basic internal | Advanced motor and device monitoring |

[Chart: Detailed ATS430 vs ATS490 Feature Comparison]

Comprehensive comparison of ATS430 vs ATS490 Altivar Soft Starters specifications and features

Practical Application Scenarios and Use Cases

ATS430 in Typical Industrial Settings

- Conveyor Belts in Discrete Manufacturing: The ATS430 offers smooth start/stop control to reduce mechanical shocks, extending belt life, and preventing product damage.

- Pump Control in Water Facilities: Reliable start-up minimizes water hammer in pipe networks, optimizing pump operation and energy consumption.

- Fans and Compressors: Prevents belt slippage and mechanical wear through gentle acceleration profiles, improving system longevity.

- Mixers and Material Handling: Ensures uniform torque during start-up to maintain product quality and reduce wear on mechanical components.

ATS490 in Critical Process and Infrastructure

- Water Treatment Plants: Controls large pumps with precision, integrates with plant control systems through broad connectivity, and offers safety functions essential in municipal water management.

- Mining Industry: Drives conveyor belts and ventilation systems, offering resilience against harsh environments and operational reliability.

- HVAC Systems for Large Facilities: Manages multiple motors, optimizes energy usage, and allows for comprehensive system monitoring and control.

- Process Manufacturing: Chemical plants and heavy industries leverage ATS490 for reliable, safe motor starting and stopping, reducing downtime and maintenance costs.

[Chart: Application Breakdown ATS430 vs ATS490]

Application areas and industry focus for ATS430 and ATS490 Altivar Soft Starters

Energy Efficiency and Sustainability Impacts

Schneider Electric prioritizes environmental responsibility in its design and manufacturing practices:

- Both models use bio-based plastics containing more than 20% renewable material and ASI-certified aluminum, reflecting sustainable material sourcing.

- Packaging uses recycled cardboard to minimize the environmental footprint.

- Integrated power and energy monitoring enables users to track and reduce energy consumption.

- High-efficiency bypass relays reduce losses, lowering operational costs and carbon emissions.

- Compliance with environmental standards like RoHS and REACH ensures low hazardous substance content, facilitating eco-friendly deployments.

Future-Proofing with EcoStruxure and Digital Integration

Both ATS430 and ATS490 are fully compatible with Schneider Electric’s EcoStruxure, a cloud-connected platform for industrial IoT solutions. EcoStruxure enables:

- Real-time data analytics and remote monitoring.

- Predictive maintenance using AI-driven insights.

- Energy management and demand response functionalities.

- Seamless upgrade paths and firmware updates.

ATS490 users particularly benefit from enhanced connectivity and cybersecurity capabilities, ensuring their motor control systems remain up-to-date and secure within growing smart factories and infrastructure networks.

Conclusion: Choosing Between ATS430 and ATS490

Selecting between the Schneider Electric ATS430 and ATS490 depends primarily on the application’s operational demands, power requirements, and integration complexity:

- Choose ATS430 for cost-effective, efficient motor control in discrete manufacturing and standard industrial processes where power requirements stay under 400kW and connectivity needs are modest.

- Opt for ATS490 when tackling complex process manufacturing, infrastructure, or heavy industries requiring up to 900kW power control, advanced safety features, broad connectivity, and certified cybersecurity to protect critical assets.

Both models exemplify Schneider Electric’s commitment to innovation, energy efficiency, and reliability, but they tailor their capabilities to distinct industrial landscapes to deliver perfect-fit motor control solutions.

This comprehensive overview and comparison present an in-depth perspective on Schneider Electric’s Altivar soft starters, ATS430 and ATS490, enabling stakeholders, engineers, and decision-makers to maximize their motor control performance aligned with modern industrial requirements.

If needed, further expansions can focus on detailed configuration guides, integration best practices, and case studies illustrating deployment successes in specific industries.