In the arena of power distribution, the significance of air circuit breakers cannot be overstated. At the core of electrical safety and reliability, these devices uphold the standards that industries and homes rely on. As guardians against electrical hazards, air circuit breakers are pivotal components that maintain the integrity of power systems. They operate with precision, immediately disrupting the current during fault conditions to prevent damage and ensure seamless flow of electricity.

We understand the vital role air circuit breakers play in protecting electrical systems. They employ compressed air to efficiently and safely extinguish electrical arcs caused by overcurrents or short circuits. By doing so, air circuit breakers mitigate risks and affirm their value as an indispensable part of modern electricity management. It’s this dedication to safety and reliability that makes air circuit breakers integral to our power distribution networks.

Key Takeaways

- Air circuit breakers serve a key role in electrical safety, instantly responding to overcurrents and short circuits to prevent system damage.

- Reliability of power distribution is bolstered by the use of these specialized interrupters, ensuring constant protection against electrical faults.

- The functionality of air circuit breakers is marked by their efficient use of compressed air to control and quench electrical arcs.

- Industrial and residential applications both benefit from the precise operation of air circuit breakers for uninterrupted electric service.

- Choosing the right type of air circuit breaker for a given voltage level and setting is crucial for optimal performance and safety.

The Role of Air Circuit Breakers in Modern Electrical Systems

Within our vast and intricate electrical infrastructure, air circuit breakers (ACBs) represent a critical safeguard, an invisible yet indispensable shield that maintains the robustness and stability of our modern networks. These sophisticated components not only bolster the safety of our systems but also epitomize advancement in electrical engineering. In our commitment to ensure the highest standards of electrical equipment protection and circuit integrity, we recognize the fundamental role ACBs play in both commercial and residential domains.

Understanding the Importance of ACBs

At the forefront of electrical protection, ACBs are engineered to respond instantaneously to any abnormalities like overcurrents and short circuits. This swift action fortifies the electrical components which are foundational to the continuous operation of our electrical systems. ACBs are more than mere devices; they are the vigilant sentinels keeping watch over the vast landscape of circuit protection, ensuring energy is delivered both safely and efficiently to the myriad of electrical equipment they serve. Our expertise in the field reinforces this understanding, as we advocate for the adoption of these essential devices in every electrical installation.

ACBs in Commercial vs. Residential Settings

Industrial settings demand robust electrical protection due to the high fault currents that heavy machinery and other energy-intensive equipment can generate. ACBs are particularly revered in such environments for their dynamic capability to handle these immense power fluctuations and prevent operational malfunctions. Conversely, in the residential realm, ACBs ensure the safety and longevity of home electrical systems, mitigating the risk to property and human life. It is in the diligent selection and application of these devices that one can appreciate their versatility—a feature that indeed deems ACBs indispensable in safeguarding electrical infrastructure regardless of its scale.

What is an Air Circuit Breaker?

In the domain of power distribution, the air circuit breaker (ACB) is paramount for ensuring operational safety and electrical reliability within our networks. As experts in switchgear technologies, we recognize the essential role that ACBs serve in safeguarding systems against high voltage transgressions and electrical mishaps. These robust mechanisms are designed to actuate under faulted states—such as overcurrents or short circuits—performing an intercession that is critical to prevent possible calamities.

Employing a revolutionary technique, the ACB utilizes an electromagnetic coil that unleashes a magnetic field to physically separate high-intensity electrical contacts. This separation induces an arc—a plasma-like state of the matter which can cause immense damage if not managed correctly. The ACB is uniquely engineered to release compressed air targeting the arc’s core, effectively snuffing it out and putting a halt to uncontrolled current proliferation through the electrical system.

ACBs, the unsung heroes of electrical safety, dynamically preserve the integrity of power distribution systems by providing a swift arc quenching response, thereby averting equipment damages and fire hazards.

We take pride in offering a myriad of ACB solutions tailored to meet the demands of a variety of applications. In our catalog, you will find units customized for usage in high-energy environments commonly found in industrial settings, as well as more compact designs suitable for residential power systems. Below is a table depicting the core features that define an ACB’s operational tenets—each a milestone in switchgear evolution.

| Feature | Description | Impact on Safety | Relevance to Power Systems |

|---|---|---|---|

| Electromagnetic Coil | Generates a magnetic field to open contacts | Enables fast, controlled interrupt of current | Crucial for accurate fault detection in complex systems |

| Compressed Air Mechanism | Extinguishes the arc formed between contacts | Prevents fire hazards and equipment damage | Essential for high-current settings |

| Mechanical Actuation | Contacts operated by secure mechanical linkages | Physical reliability in triggering circuit interruption | Foundational in both commercial and residential settings |

| Protective Relays | Senses abnormal currents and initiates tripping | Automates response to minimize reaction time | Supports system’s long-term stability and integrity |

For the uninitiated, the ACB could be simply another component in a vast electrical ensemble, but for us, the electrical connoisseurs, it’s a linchpin in the modern electrical safety apparatus. Always striving for excellence, we ensure each air circuit breaker leaving our facility is a testament to our commitment to safety and quality in power distribution. Let us introduce you to an ACB that matches not only your technical requirements but also supports the unwavering efficiency and security of your electrical systems.

Comprehensive Overview of Air Circuit Breaker Operation

As pioneers in electrical safety, we delve deep into the operation of Air Circuit Breakers (ACBs). These devices are crucial for high voltage equipment management, ensuring that the flow of electricity is terminated when a fault is detected, to protect both systems and personnel. ACBs play an indispensable role in mitigating electrical risks, but what enables these efficient guardians to maintain high standards of electrical safety in our systems?

The Science Behind Arc Quenching

The mechanism that ACBs employ to break electrical circuits is known as arc quenching. This highly effective process is integral to the ACB’s operation, creating an arc voltage that exceeds the system’s supply voltage. It is this scientific phenomenon that allows ACBs to successfully interrupt an electric current and avert system failures. The swift and precise nature of arc quenching is critical to maintaining the integrity and functionality of the extensive networks of high voltage equipment that power our industries and homes.

Role of Compressed Air in ACBs

Central to the arc quenching process is the role of compressed air. In our quest for peak electrical safety, we utilize this powerful medium to cool down the arc rapidly, divide it into smaller, more manageable arcs, and extend the arc’s path to increase its resistance. This is where the brilliance of ACBs shines through—they not only prevent electrical overloads but do so with such alacrity that the regular functioning of our electrical systems experiences minimal to no disruption. It’s through these sophisticated operations that ACBs ensure the long-standing stability and safety of our electrical frameworks.

We take immense pride in our ACBs, knowing that with each operation, they reinforce the barrier between routine electrical flow and potential catastrophe. In every industrial and residential setting that demands reliability, ACBs stand ready to protect and serve, as silent yet formidable sentinels of our electrical safety.

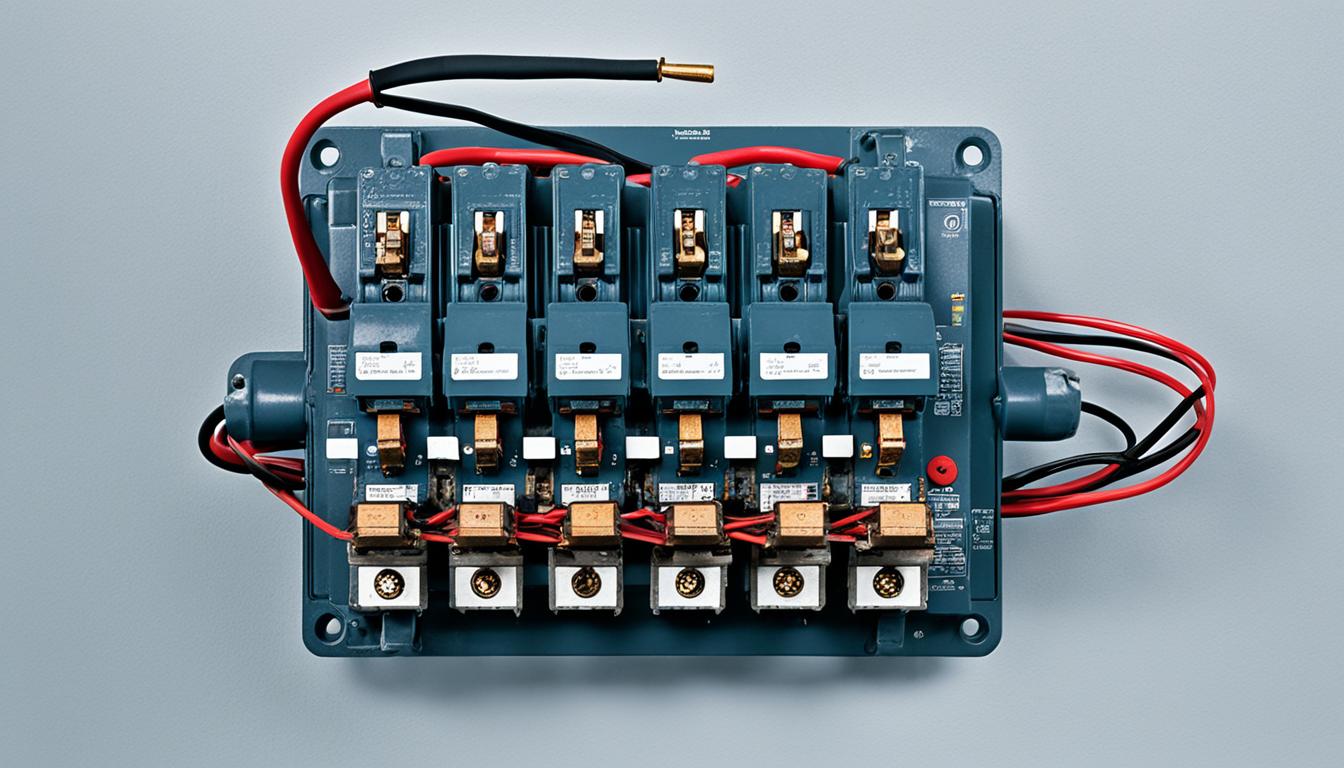

Detailed Look into Air Circuit Breaker Components

In the world of industrial controls, electrical systems, and electrical components, air circuit breakers (ACBs) stand as central figures, ensuring operational safety and precision. The complex interplay of an ACB’s parts not only dictates its reliability but also its efficacy in protecting our intricate electrical networks. Each component contributes to the overall functionality, playing a specific role that is crucial to the performance of the breaker.

The Function of Blast Valves

A quintessential feature within ACBs, the blast valve, plays a critical role in redirecting and quenching the arc. These valves are engineered to open rapidly upon detection of an electrical fault, ensuring that the arc is efficiently extinguished by a surge of pressurized air.

Understanding Arcing Contacts and Probes

Delving further into an ACB’s anatomy, we encounter the main and auxiliary contacts. The primary contacts, composed of durable copper, are responsible for carrying the current during normal operations. When a fault is detected, these contacts must separate, giving rise to an electrical arc. It is here that the auxiliary contacts, crafted from robust copper alloy, prove invaluable. They protect the main contacts from direct exposure to arcing, effectively extending their lifespan by bearing the initial arc creation.

The arcing contacts and probes, along with the blast valves, synergize to guide arcs into arc chutes—a chamber made of refractory materials designed for effective arc extinction. Together with the trip unit, housing protective relays and sensors, these elements form a comprehensive defense mechanism, preserving the integrity of electrical systems across a breadth of industrial and residential settings.

| Component | Description | Purpose | Contribution |

|---|---|---|---|

| Blast Valve | Device that releases pressurized air | To push and extinguish the electrical arc | Proactively preventing damage during faults |

| Main Contacts | Copper components conducting current | To carry the regular operating current | Foundational to ACB’s primary functionality |

| Auxiliary Contacts | Copper alloy components for arcing | Shielding main contacts during electrical faults | Enhancing the durability and reliability of ACBs |

| Arc Chute | A refractory chamber for arc quenching | Cooling and deconstructing the arc post-separation | Ensuring the safety of both equipment and personnel |

| Trip Unit | Relays and sensors for fault monitoring | Detecting anomalies and initiating tripping sequence | Automating responses to electrical irregularities |

Our commitment to excellence in the field of electrical controls extends to every ACB component we offer. It is our belief that understanding these fundamental parts is essential for those entrusted with maintaining the cadence of modern electrical systems—systems that are both dynamic and demanding. We invite our clients to explore with us the intricacies of ACBs, to better appreciate and utilize the sophistication that they bring to industrial and residential electrical systems.

Demystifying the Types of Air Circuit Breakers

Understanding the breadth of options among air circuit breakers is essential in selecting the perfect ACB for the varied requirements of modern electrical systems. Every electrical environment demands its unique protection, hence our focus on providing detailed insights into the different types of ACBs available on the market. Let’s dissect these types to ensure you’re equipped with the knowledge to make an informed decision.

Whether you are managing a low-voltage residential setup or an industrial system requiring higher voltage handling, there is an air circuit breaker designed to meet those specific needs. From the Plain Brake Type ACB, favored for low-voltage applications, to the robust Air Blast Circuit Breaker suitable for medium-to-high voltage circumstances, each ACB variant stands out with unique properties and advantages for safety and control.

| Type of ACB | Voltage Handling | Notable Feature | Primary Usage |

|---|---|---|---|

| Plain Brake Type ACB | Low Voltage Systems | Air pressure for arc elongation and extinguishment | Residential and light commercial settings |

| Magnetic Blowout Type ACB | Below 11,000 Volts | Magnetic field assists in arc movement | Transformer and generator protection |

| Air Chute ACB | High Voltage Systems | Copper and silver elements for enhanced conductivity | Utility substations and primary contacts protection |

| Air Blast Circuit Breaker | Up to 15 KV | Pressurized air for efficient arc movement and quenching | Medium-to-high voltage industrial applications |

Each type of **Air Circuit Breaker** plays a pivotal role in its respective field, offering protection tailored to the electrical load and environmental needs. The diversity among ACBs enables us to ensure continuity and security across a spectrum of electrical systems.

We take pride in our deep understanding of the nuances related to the Plain Brake Type ACB, Magnetic Blowout Type ACB, Air Chute ACB, and Air Blast Circuit Breaker. With your system’s safety as our ultimate goal, we leverage our expertise to guide you through the complex landscape of ACBs. Trust us to illuminate the path towards optimal electrical protection, no matter the voltage or environmental requirements.

When choosing an ACB, consider it a strategic investment—an investment in the sustainability and safety of your electrical systems. Together, we ensure that this choice is informed, precise, and perfectly aligned with your operational needs.

Strategic Applications of Air Circuit Breakers

In the vast landscape of industrial and power distribution systems, air circuit breakers (ACBs) are the stalwarts that protect a wide range of electrical equipment from catastrophic failure. At the very heart of electrical safety, ACBs are the linchpins that cater to the high energy needs of contemporary circuits, ensuring that every instance of power overload is deftly managed.

Protecting High Energy Industrial Equipment

Our industrial landscapes are populated with machinery that embodies high energy consumption and operation. It’s here that ACBs are truly irreplaceable. They stand guard over heavy industrial equipment, preventing the adverse effects of overcurrents and short circuits that can lead to costly downtimes. ACBs serve as a protective shield, safeguarding mission-critical electrical machinery such as motors, transformers, and generators, which form the backbone of industrial productivity.

Significance in Power Distribution Networks

When it comes to power distribution systems, ACBs are the unsung heroes. These robust devices ensure that power flows uninterrupted, minimizing disruptions in supply and protecting the network from the instabilities caused by excessive energy flows. Their strategic role cannot be overstated; without ACBs, power distribution networks could be subjected to instability and inefficiency, risking both loss of service and equipment damage.

ACBs’ decisive response to electrical irregularities establishes them not just as essential components but as key protectors of our modern electrical infrastructure.

Whether you’re operating in an industrial plant or managing a power distribution network, our ACBs provide peace of mind, knowing that they reliably perform when it’s most critical. Unwavering in their operation, these breakers are indispensable assets in the pursuit of electrical system endurance and stability.

Air Circuit Breaker Maintenance and Testing Protocols

As we delve into the maintenance and testing of air circuit breakers, it’s essential to stress the importance of these practices in ensuring the efficacy and longevity of the electrical system. Adherence to these protocols is not only about compliance but about ensuring the continuous, safe operation of power distribution networks. Expert attention to air circuit breaker testing forms the bedrock of electrical system maintenance, securing the heartbeat of industry and infrastructure.

Ensuring ACB Longevity through Regular Testing

Meticulous air circuit breaker testing is crucial in predicting and precluding potential failures within electrical systems. Through scheduled functional tests, our adept technicians replicate fault conditions to affirm each ACB’s operational readiness. This precise process, a cornerstone of electrical system maintenance, highlights any issues needing rectification before escalation to actual faults.

Preserving the reliability of ACBs through scheduled testing—a practice we champion—is akin to guarding the sentinels of our electrical infrastructure.

Professional Assessment and Maintenance

Our comprehensive maintenance regimen is designed to extend the service life of ACBs, underpinning the continuity of electrical operations. Regular visual inspections are complemented by diligent cleaning procedures, ensuring the removal of any deleterious dust accumulation. Lubrication, in accordance with the manufacturer’s instructions, is methodically applied to maintain the mechanical finesse of ACBs.

| Maintenance Task | Objective | Frequency | Outcome |

|---|---|---|---|

| Visual Inspections | To identify signs of wear or damage | Monthly | Prevention of unexpected breakdowns |

| Cleaning | To prevent dust and debris accumulation | Bi-annually | Optimization of ACB performance |

| Lubrication | To ensure smooth operation of moving parts | As per manufacturer’s guidelines | Reduction in mechanical friction |

| Functional Testing | To verify correct operation under fault conditions | Annually | Assurance of protective functions |

| Electrical Testing | To measure contact and insulation resistance | Every 3-5 years | Detection of early signs of deterioration |

It is our unwavering mission to ensure each air circuit breaker within your purview meets the high standards of safety and efficacy. By proactively engaging in detailed ACB testing and maintenance, we fortify the very systems that drive our modern world.

Maximizing Safety with Air Circuit Breaker Solutions

We at Triple C Electric recognize the paramount role that air circuit breakers (ACBs) play in enhancing the electrical system safety and upholding system integrity in a vast array of industries. Our focus on air circuit breaker efficiency is at the forefront of our operations to ensure that your electrical systems are protected with the most advanced technology in ACB design. It’s this dedication to integrating superior safety mechanisms that solidifies our commitment to your peace of mind.

In every ACB solution we provide, our aim is to create an environment where the safety of personnel and equipment is never in question. ACBs are designed with precision to detect and interrupt electrical overcurrents and short circuits swiftly, preventing any disruption that could impede on the operations or safety of a facility. Facility managers and engineers alike can trust in the reliability of our ACBs to maintain a safe and efficient electrical system—no matter the challenges.

To elucidate further on the efficiency of our ACBs, we present a comprehensive table that showcases how each component of an air circuit breaker contributes to a safer and more reliable electrical system:

| ACB Component | Function | Contribution to Safety | Impact on Efficiency |

|---|---|---|---|

| Electronically Controlled Mechanism | Automatically detects faults and interrupts circuit | Quick response reduces risk of damage and danger | Automated processes streamline system operations |

| Compressed Air System | Extinguishes electric arcs effectively | Non-hazardous arc quenching medium enhances personnel safety | Minimizes downtime by preventing equipment damage |

| Intelligent Sensing Technology | Monitors electric load and system health | Real-time detection of irregularities ensures proactive protection | Prevents energy wastage and optimizes load management |

| Modular Design | Allows customization to fit specific system requirements | Customized solutions avoid overengineering and enhance safety margins | Adaptable configurations lead to better system performance |

With such inherent features, our ACBs stand as formidable guardians against electrical faults. Proudly delivered by Triple C Electric, each breaker undergoes rigorous testing and quality assurance to ensure they meet the high expectations of our clients. Choose to safeguard your operations with the unrivaled protection of our air circuit breaker solutions.

The Advantages of Using Air Circuit Breakers

When it comes to maintaining robust and secure electrical operations, the unmatched capabilities of Air Circuit Breakers (ACBs) play a pivotal role. Our unwavering commitment to excellence in circuit protection is encapsulated in our persistent deployment of ACBs across various industrial applications. They not only exemplify resilience in the face of electrical threats but also provide a platform for the implementation of advanced safety measures.

High Breaking Capacity and Its Merits

ACBs are distinguished by their high breaking capacity, allowing them to address large fault currents that are characteristic of industrial environments. This exceptional capacity equips ACBs to effectively handle the intense energy demands encountered in rigorous industrial applications, without compromising the stability or efficiency of our electrical systems.

Our ACBs, designed to address high-risk scenarios, fortify electrical networks against the most strenuous conditions, safeguarding both assets and personnel.

In the pursuit of sustainable electrical operations, it is crucial to acknowledge that high breaking capacity is not an end in itself. It is a means to achieving an uninterrupted service delivery, minimizing downtime, and preventing the catastrophic aftermath of electrical failures.

Customization for Advanced Circuit Protection

The versatility of our ACBs is showcased through their customizable protection features. We believe in a tailored approach to electrical safety, which is why we offer adjustable current settings and varied tripping curves to create a customized protection plan that aligns seamlessly with the unique requirements of various equipment and facilities.

The ability to fine-tune these devices to specific operational needs has elevated ACBs beyond a standard safety component to an enabler of precise and reliable electrical operations. This flexibility, allowing accommodation for controlled overloads in particular scenarios, underscores the innovative application of ACBs as an integral tool in circuit protection strategies.

ACBs provide the personalized electrical infrastructure essential to the diverse landscapes of modern industry, empowering our commitment to deliver tailored circuit protection solutions.

Engage with our team to explore how the strategic application of ACBs can revolutionize your approach to circuit protection and ensure the longevity and integrity of your electrical systems.

The Durability and Longevity of Air Circuit Breakers

Renowned for their durability and long service life, Air Circuit Breakers (ACBs) stand out as quintessential components in the realm of durable electrical equipment. Their robust construction is testament to the central importance of ACB robustness when it comes to ensuring consistent performance in highly demanding environments. At the heart of these critical devices lies a combination of resilient materials and innovative design, which come together to provide a dependable safeguard against electrical faults.

Materials and Design Contributing to ACB Robustness

The superior strength and durability of ACBs are attributed to their high-quality materials and meticulous design. Made to endure severe operational conditions, ACBs incorporate copper and silver components known for their excellent electrical conductivity and corrosion resistance. Their mechanical solidity is fortified through exacting design standards that prep them for long-term use, even in the harshest of settings. It is this relentless attention to quality that certifies ACBs as a key player among durable electrical equipment.

Critical Maintenance for Prolonged Service Life

To maintain their status as robust and reliable, ACBs require a disciplined maintenance routine. This involves regular visual inspections to identify any potential issues that could compromise their functionality. Functional and electrical testing play a proactive role in preventing failures, while scheduled cleaning ensures that the ACBs remain free from dirt and debris which could otherwise lead to operational inefficiencies. Lubrication of moving parts, as per the manufacturers’ specifications, is crucial for maintaining the fluidity of operation. Such stringent maintenance protocols significantly contribute to the prolonged service life of ACBs.

| Maintenance Aspect | Benefit | Frequency | Expected Outcome |

|---|---|---|---|

| Visual Inspections | Detect early signs of wear or damage | Quarterly | Preserve ACB integrity and functionality |

| Functional Testing | Ensure operational readiness and fault response accuracy | Annually | Reliable tripping mechanisms during faults |

| Cleaning Procedures | Maintain optimal environmental conditions for ACB components | Bi-annually | Prevention of contaminant build-up and overheating |

| Lubrication | Reduce friction in moving parts | As recommended by manufacturer | Smooth and consistent breaker operation |

Our rigorous adherence to these maintenance practices guarantees the ACBs we offer are capable of consistent and long-lasting service, making them a valuable investment in the continuity and safety of electrical systems.

Air Circuit Breakers in Industrial Settings

Within the industrial sector, the provision of stable and secure electrical supply is paramount. We understand the complexities of industrial controls, and it’s within these intricate systems that Air Circuit Breakers (ACBs) serve as fundamental components for electrical safety and machinery protection. As dedicated guardians of electrical distribution, ACBs diligently protect against disruptions caused by unforeseen electrical surges.

ACBs are particularly crucial in industries where equipment must tolerate heavy loads and frequent fault conditions with minimal downtime. Instantaneous response to these faults ensures the protection of essential equipment such as motors and generators, which are the lifeblood of industrial productivity. This underscores the importance of ACBs in maintaining operational continuity.

By integrating ACBs into the electrical infrastructure, we fortify our commitment to delivering comprehensive machinery protection. The sophisticated design of ACBs allows for their deployment in a multitude of settings, ranging from highly-sensitive equipment that requires nuanced electrical regulation, to heavy-duty machinery that performs under staggering electrical demands.

Let us delve into the specifications of ACBs that make them so indispensable for industrial usage:

| Feature | Benefits | Industrial Application |

|---|---|---|

| Instantaneous Tripping Mechanism | Prevents extensive equipment damage from overcurrents | Protection of heavy machinery and production lines |

| Customizable Settings | Allows fine-tuning for specific industry needs | Varied industrial environments with unique electrical demands |

| High Breaking Capacity | Manages large fault currents efficiently | High-power industrial facilities such as metallurgy or petrochemical plants |

| Durability and Longevity | Reliable performance over extended periods, reducing maintenance costs | Continuous, energy-intensive operations |

It is through our rigorous selection of ACBs, each tailored to the intricacies of industrial applications, that we are able to affirm their role as critical to industrial controls. ACBs embody the confluence of safety, precision, and reliability. They are not just devices but strategic investments in the enduring efficiency and safety of industrial operations.

Whether safeguarding small-scale assembly machinery or massive power generators, ACBs deliver unmatched protection. It is no overstatement to say that they are the backbone of electrical safety within the industrial setting. It is our pledge to continuously innovate and provide ACBs that not only meet but exceed the exacting standards of modern industrial protective measures.

Ensuring Uninterrupted Power in Commercial Buildings with ACBs

In the landscape of commercial real estate, maintaining consistent, safe electrical output is paramount. Air Circuit Breakers (ACBs) play a pivotal role in ensuring the reliability and safety of electrical circuits in commercial buildings. The critical function of ACBs in protecting infrastructure cannot be understated, as they actively prevent electrical fires and equipment failures.

ACBs in Lighting and HVAC System Protection

Lighting and HVAC systems are the lifeline of a building’s functional and comfortable environment. ACBs ensure electrical circuit safety and contribute to the HVAC protection, making them crucial for the smooth operation of these systems. Particularly in scenarios where variable frequency drives and other sensitive components are used, ACBs accurately detect and mitigate faults, significantly reducing the chances of electrical hazards.

Electrical Safety for High-Traffic Commercial Spaces

High-traffic areas in commercial buildings, such as shopping centers, office buildings, and hotels, demand unwavering electrical stability. ACBs are indispensable in managing complex electrical demands and are central to the safety protocols of these spaces. Not only do they protect the multitude of electrical devices in use, but they also ensure the safety of the public and staff working within these environments.

| Feature | Role in Commercial Buildings | Benefit |

|---|---|---|

| Instantaneous Fault Detection | ACBs quickly identify overcurrents and electrical faults. | Minimizes the risk of power outages and protects against electrical fires. |

| Robust Arc Quenching | Effectively manages arc faults in high-power circuits. | Prevents damage to electrical equipment and infrastructure. |

| Automated Resetting | Allows for quick recovery after a fault interruption. | Reduces downtime and keeps essential services operational. |

| User-configurable Settings | ACBs can be tailored to the specific load requirements of a facility. | Ensures optimal protection for diverse electrical equipment used within the building. |

Our mission centers on providing reliable and efficient ACB solutions that support the energy management needs of commercial buildings across the United States. By integrating our ACBs within your electrical safety systems, you ensure not just compliance with standards, but also a commitment to protecting assets and people from electrical harm.

Key Role of Air Circuit Breakers in Power Generation

In the realm of power generation, the stability and efficiency of our electrical systems hinge on the reliable operation of core components such as transformers, generators, and the protective measures that secure transmission lines. One such foundational protective measure comes in the form of Air Circuit Breakers (ACBs), which provide indispensable defense against electrical faults that could disrupt the seamless flow of power across the grid.

ACBs are specifically designed for power generation and distribution, ensuring the reliability of electrical systems by guarding against the detrimental impact of overcurrents and short circuits. By defending the backbone of our electrical grid — the transformers, generators, and transmission lines — ACBs contribute significantly to the prevention of outages and maintenance of service continuity.

Recognizing the critical nature of these components in power generation, they are engineered to act promptly upon the detection of irregularities in the current, swiftly severing connections that could endanger the electrical network. The strategic installation of ACBs along transmission lines enables a multi-tiered protection system, further bolstering the overall safety and reliability of power distribution infrastructures.

Moreover, as we continue to push the limits of what our power generation facilities can do, the role of ACBs only grows in significance. Their ability to handle high energy levels effortlessly and reliably makes them an integral part of our commitment to supplying uninterrupted electricity to meet the demands of a rapidly advancing society.

The vigilant operation of Air Circuit Breakers is a testament to our unyielding pursuit of electrical system reliability. They underpin our capability to distribute power safely and effectively, proving to be vital assets in today’s energy landscape.

- ACBs protect the essential components of power generation facilities.

- Their maintenance of transmission lines protection is key to uninterrupted service.

- ACBs help prevent the costly consequences of electrical disruptions.

- They ensure ongoing operations adhere to the highest standards of safety and efficiency.

Through focused innovation and stringent testing, we strive to enhance the capabilities of our ACBs, ensuring they not only meet but exceed the dynamic needs of power generation and distribution. It is with a strong sense of responsibility that we deliver these critical components, supporting the backbone of our nation’s electrical infrastructure and the continuous reliability of our power systems.

Guidelines for Regular Air Circuit Breaker Maintenance

In our role as electrical safety stewards, we emphasize the critical importance of regular maintenance for Air Circuit Breakers (ACBs). Electrical maintenance practices are pivotal in ensuring that ACBs operate optimally, thus maintaining system integrity and preventing untimely failures. By establishing rigorous ACB testing protocols, we underpin the seamless functionality of these essential components for years to come.

Standard Operational Checks and Balancing

Operational checks are the foundation of routine ACB maintenance, where we meticulously evaluate and calibrate each unit to guarantee precise operation. Our dedicated teams conduct balancing tests to affirm that ACBs maintain their calibrated settings under various load conditions. This not only ensures the breaker’s reliability but also fortifies the safety across electrical systems.

Periodic Inspection and Cleaning Importance

Our commitment to excellence necessitates thorough periodic inspections of ACBs to identify any signs of wear or damage. We believe that a vigilant eye helps to nip potential issues in the bud, safeguarding against electrical mishaps. Cleaning is also a non-negotiable part of the maintenance cycle, aimed at preserving proper ventilation and the overall health of ACBs. Diligence in following the recommended maintenance schedules is our mantra for extending the lifespan of these indispensable circuit protection devices.

| Check | Description | Frequency | Expected Outcome |

|---|---|---|---|

| Diagnostic Assessment | Evaluation for operational integrity | Annually | Ensuring system accuracy and readiness |

| Calibration Verification | Testing and adjusting settings | Semi-annually | Maintaining precise protective measures |

| Physical Inspection | Look for mechanical defects and contact erosion | Quarterly | Early fault detection and correction |

| Component Cleaning | Removing dust and contaminants | Bi-annually | Optimal operation and longevity |

Through these essential electrical maintenance practices, we stand firm in our pledge to deliver not just ACBs, but unwavering reliability and safety within the electrical systems we serve. It is through these vigilant efforts that we sustain the high standards set forth in our industry.

Triumphs of Technology: Air Circuit Breakers in Modern Systems

As champions of the forefront in electrical protection, we continuously celebrate the leaps and bounds made through ACB innovation. Witnessing the integration of advanced air circuit breakers into modern electrical systems exemplifies a significant trajectory of progress. These pivotal components contribute extensively to elevating safety management protocols, resonating with the core of our values—uncompromised reliability and safety.

Innovations in ACB Design and Efficiency

At the heart of modern electrical systems, air circuit breakers are redefining efficiency standards. Through ingenious design modifications and the implementation of state-of-the-art materials, we are amplifying the resilience of ACBs. Our focus remains on diminishing the occurrence of faults and integrating systems seamlessly into the electrical grid. This evolution manifests in cleaner interfaces, automated diagnostics, and sophisticated tripping mechanisms that collectively enhance the functionality of electrical apparatus.

Embracing ACB innovation translates directly to an uplifted benchmark of efficiency, partnering robust design with impeccable system stability—a true homage to the vibrant progress of electrical technology.

ACBs and The Future of Electrical Safety Management

Envisioning the future of electrical safety management, we anticipate air circuit breakers to be pivotal in scripting new paradigms of electrical practice. Groundbreaking improvements in ACB technology have fortified their identity as the sentries of energy distribution. With visionaries and experts crafting features to anticipate and react impeccably to dynamic electrical states, ACBs are sculpted to become even more indispensable in the integrated systems of tomorrow.

The circuitry of the future demands agile, responsive, and intuitively safe operations that ACBs will inherently embrace. Harnessing data analytics and IoT connectivity, next-generation ACBs will provide a greater spectrum of control and insights, heralding preventative safety measures and mitigating risks with unseen precision. This apex of ACB innovation is the cornerstone of modern electrical systems, imbuing every circuit with unrivaled protection and certainty.

Our collective journey with air circuit breakers is one paved with revolutionary milestones—each step forward in ACB innovation is a stride towards the heightened efficacy in energy management and safety that modern electrical systems strive for. As stewards of this transition, we embrace the transformative power of technology and anticipate a future where electrical systems function with an impeccable balance of power and protection.

Our collective journey with air circuit breakers is one paved with revolutionary milestones—each step forward in ACB innovation is a stride towards the heightened efficacy in energy management and safety that modern electrical systems strive for. As stewards of this transition, we embrace the transformative power of technology and anticipate a future where electrical systems function with an impeccable balance of power and protection.

Conclusion

As we reflect on the pivotal role of Air Circuit Breakers (ACBs) in fostering reliable electrical systems, it’s clear that their intrinsic value cannot be overstated. From the myriad of air circuit breaker benefits — such as handling high voltages with aplomb to their sophisticated arc quenching capabilities — ACBs have proven to be indispensable allies in effective circuit protection. Our evolving electrical landscape relies heavily on these robust devices to maintain operational integrity across both industrial and commercial environments.

Moreover, the adaptability of ACBs, combined with their capacity for customization, addresses the intricacies of diverse applications, underscoring their versatility. In our efforts to achieve the safest and most reliable electrical systems, the tailored approach that ACBs offer has become a defining factor. It is this flexibility, alongside their high-end performance, that assures us of continued protection and the peace of mind that comes with knowing our systems are safeguarded against electrical anomalies.

As we peer into the future of electrical safety and efficiency, ACBs stand at the forefront, poised for integration into ever more advanced systems, reflective of their enduring relevance. Embracing the continuous technological advancements, we remain committed to ensuring that our clients benefit from the highest level of protection that ACBs provide. For us, promoting the import of ACBs goes hand in hand with our mission to support the growth and stability of industries that make up the fabric of our electrified world.

FAQ

What is the primary function of an Air Circuit Breaker?

The primary function of an Air Circuit Breaker (ACB) is to provide circuit protection by interrupting the flow of electricity when a fault, such as an overcurrent or short circuit, is detected. This safeguards electrical systems and connected devices from damage.

How does compressed air assist in the operation of an ACB?

Compressed air is used in ACBs to extinguish electrical arcs that may occur during fault conditions. It cools the arc, splits it, and elongates its path, increasing resistance and facilitating rapid quenching of the arc to maintain system stability and prevent component damage.

Can Air Circuit Breakers be used in both commercial and residential settings?

Yes, Air Circuit Breakers are versatile and can be used in both commercial and residential settings. In commercial environments, they protect heavy machinery and prevent energy malfunctions, while in residential settings they contribute to the safety of home electrical systems.

What are the different types of Air Circuit Breakers available?

There are several types of Air Circuit Breakers available, including the Plain Brake Type ACB for low-voltage scenarios, the Magnetic Blowout Type ACB suitable for voltages below 11,000 volts, the Air Chute ACB for high-voltage situations, and the Air Blast Circuit Breaker for medium-to-high voltage levels up to 15 KV.

Why are ACBs particularly important in industrial and power distribution settings?

ACBs are crucial in industrial and power distribution settings due to their high breaking capacity and ability to handle large fault currents. They act as protective shields for electrical machinery, minimizing downtime and maintaining a stable power supply to support uninterrupted operations.

What routine maintenance should be performed on an Air Circuit Breaker?

Routine maintenance for an Air Circuit Breaker includes regular visual inspections, cleaning to prevent dust accumulation, lubrication as recommended by the manufacturer, and functional testing to simulate fault conditions and ensure proper operation. Electrical testing for contact resistance and insulation resistance is also important for identifying potential issues.

What advantages do Air Circuit Breakers offer?

Air Circuit Breakers offer several advantages including enhanced electrical safety, customizable protection features such as adjustable current settings and tripping curves, high breaking capacity, and adaptability to a wide range of industrial and commercial applications. They contribute to creating a stable and safe electrical environment.

How do innovations in ACB technology contribute to modern electrical systems?

Innovations in ACB technology contribute to modern electrical systems by enhancing safety management and reliability. These advancements include improvements in design and efficiency, as well as the integration of new features that reduce risks and align with the evolving needs of energy distribution and circuit protection.

What role do Air Circuit Breakers play in ensuring uninterrupted power in commercial buildings?

In commercial buildings, Air Circuit Breakers play a vital role by protecting lighting, HVAC systems, and other utilities from electrical faults. They ensure a stable power supply and prevent disruptions, especially in high-traffic areas, thus safeguarding equipment and occupants alike.

How do Air Circuit Breakers protect essential components in the electrical grid?

Air Circuit Breakers protect essential components in the electrical grid, such as transformers, generators, and transmission lines, by acting as a critical defense against electrical faults. They ensure a stable and reliable power supply, supporting the continuous flow of electricity across the network.

Source Links

- https://mytech-info.com/air-circuit-breaker/

- https://triplec-electric.com/blog/guide-to-acb-air-circuit-breakers/

- https://electricaljunctiondubai12.medium.com/air-circuit-breaker-acb-construction-operation-types-and-uses-fff17f6d7343