In an era where electrical infrastructure forms the backbone of our digital economy, the need for advanced thermal monitoring solutions has never been more critical. Schneider Electric’s development of the TH110 wireless thermal sensor represents a pivotal response to mounting safety concerns, economic pressures, and technological demands in electrical systems worldwide. This comprehensive analysis explores why Schneider Electric’s investment in TH110 technology is not merely beneficial but essential for the future of electrical safety and operational efficiency.

Close-up of a copper electrical connector with a Schneider Electric thermal sensor installed, illustrating

The Alarming Reality of Electrical Fires and Safety Hazards

Statistical Evidence of Crisis

The statistics surrounding electrical fires present a sobering picture of the challenges facing modern electrical infrastructure. In the United States alone, electrical system failures cause over 50,000 fires annually, resulting in approximately $1.3 billion in property damage. The United Kingdom experiences similar challenges with approximately 20,000 house fires per year attributed to faulty electrics, emphasizing the global scope of this problem. These figures represent more than mere statistics—they reflect human lives at risk, business operations threatened, and economic stability undermined.1684808226198.jpgyoutube

Between 2011 and 2021, workplace electrical fatalities totaled 1,201 incidents according to OSHA and Bureau of Labor Statistics reports. Perhaps more concerning is that 69% of all electrically related fatalities occurred in non-electrical occupations, highlighting how electrical hazards extend far beyond specialized electrical work environments. This data underscores the universal need for enhanced electrical monitoring systems across all industries and applications.interestingautomation+1

The construction industry bears the heaviest burden, experiencing 855 electrical fatalities during this period, followed by professional and business services with 212 fatalities. Arc flash incidents, while representing only 8% of electrical fatalities, account for 37% of serious injuries, with up to 80% of OSHA-reported electrical injuries involving thermal burns from arc flashes. These statistics illuminate why preventive thermal monitoring technologies like the TH110 are not luxury additions but critical safety necessities.

The Connection Between Temperature and Electrical Failures

Research consistently demonstrates that loose connections, deteriorating components, and inadequate maintenance create conditions where increased electrical resistance leads to dangerous temperature elevations. Studies indicate that 25% of electrical fires originate from faulty connections, making continuous thermal monitoring essential for preventing catastrophic failures. When electrical connections begin to deteriorate, the resulting increase in resistance generates heat, creating a progressive failure cycle that can culminate in fire, explosion, or equipment destruction.

The thermal runaway phenomenon represents one of the most dangerous aspects of electrical system failures. As components heat up due to increased resistance, their electrical properties change, often creating conditions that accelerate further heating. Without early detection systems like the TH110, this process can progress undetected until reaching catastrophic failure levels. Traditional periodic infrared inspections, while valuable, can miss rapidly developing problems that occur between scheduled maintenance intervals.

Schneider Electric’s Strategic Response: The TH110 Solution

Revolutionary Technology Features

Schneider Electric’s TH110 wireless thermal sensor addresses these critical safety challenges through innovative design and advanced technology integration. The sensor operates within a wide temperature range of -25°C to +115°C, with maximum tolerance up to 150°C, ensuring reliable operation across diverse environmental conditions. Its ±1°C accuracy provides precision necessary for detecting subtle temperature changes that precede serious electrical failures.

Schneider Electric Easergy TH110 wireless thermal sensor kit, including sensors, mounting strap, accessories, and manuals

The TH110’s energy-harvesting capability represents a breakthrough in maintenance-free monitoring technology. By drawing power from the electromagnetic field generated by current-carrying conductors, the sensor eliminates battery replacement requirements while ensuring continuous operation as long as electrical current flows through monitored components. This self-powered design addresses one of the primary obstacles to widespread sensor deployment: ongoing maintenance costs and reliability concerns associated with battery-powered devices.

The sensor’s compact 31x31x14mm dimensions and 15-gram weight enable installation in confined spaces typical of electrical switchgear and distribution equipment. Its Zigbee Green Power communication protocol provides reliable wireless data transmission up to 100 meters in open environments, with reduced but adequate range in industrial settings with metallic barriers. The 60-second transmission interval ensures real-time monitoring capability while optimizing power consumption and network efficiency.

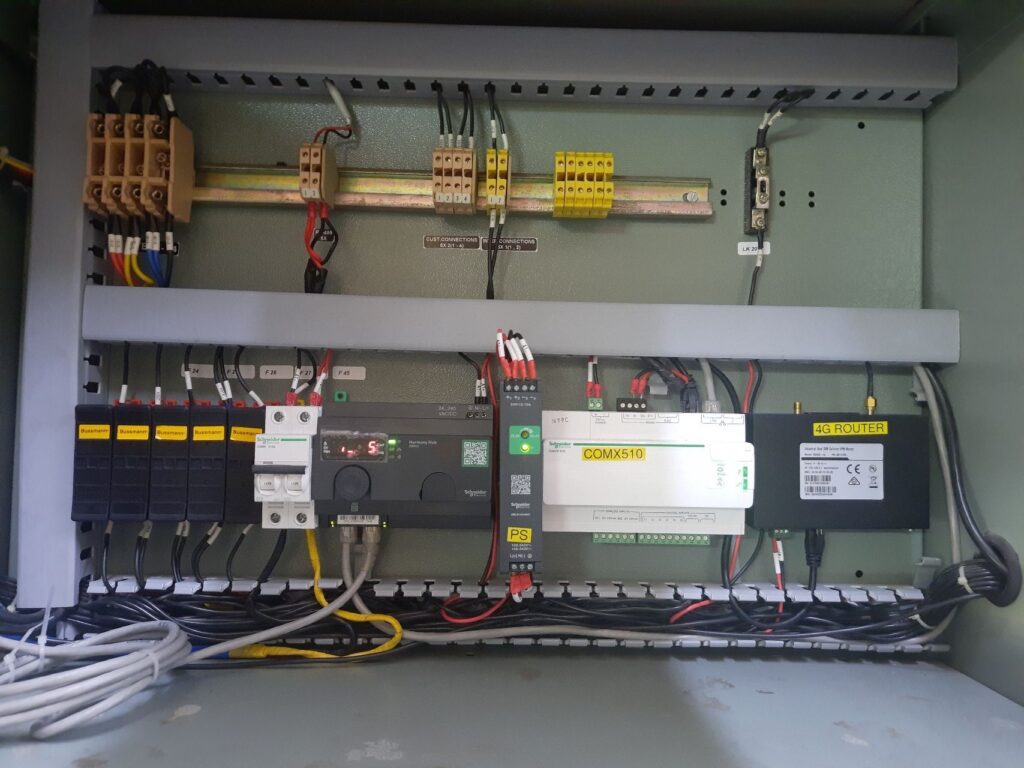

Integration with EcoStruxure Platform

The TH110’s integration with Schneider Electric’s EcoStruxure IoT platform transforms individual temperature measurements into comprehensive operational intelligence. EcoStruxure provides cloud-based analytics, historical trending, and predictive maintenance capabilities that extend far beyond simple temperature monitoring. This integration enables sophisticated anomaly detection, predictive failure analysis, and automated alerting systems that can prevent equipment failures before they occur.

Wireless temperature monitoring system setup showing interconnected sensors, modules, and real-time monitoring via web and app interfaces

The platform’s machine learning capabilities analyze temperature patterns, identifying subtle changes that might indicate developing problems invisible to conventional monitoring approaches. By comparing individual equipment performance against industry benchmarks and historical data, EcoStruxure can provide predictive insights that enable proactive maintenance scheduling and risk mitigation strategies. This capability transforms thermal monitoring from reactive problem identification to proactive system optimization.

Economic Imperative for TH110 Development

Cost-Benefit Analysis of Preventive Monitoring

The economic justification for TH110 development becomes clear when examining the costs of electrical failures versus prevention. Electrical fires result in billions of dollars in annual property damage, while unplanned downtime in industrial facilities can cost hundreds of thousands of dollars per hour. Even a single prevented fire or equipment failure can justify the entire investment in thermal monitoring systems, creating compelling return on investment scenarios for end users.

Predictive maintenance enabled by continuous thermal monitoring can reduce maintenance costs by 15-25% while preventing 20-25% of equipment failures. These savings result from optimized maintenance scheduling, extended equipment life, and avoided emergency repairs. Wireless sensor deployment offers additional 25-30% savings in installation costs compared to wired alternatives, making widespread sensor deployment economically feasible.

The TH110’s maintenance-free operation eliminates ongoing service costs associated with battery replacement, calibration, and device updates. Over a typical 20-year service life, these operational savings can exceed initial equipment costs, particularly in large installations with hundreds or thousands of monitoring points. This economic model makes thermal monitoring accessible to organizations that previously considered such systems prohibitively expensive.

Market Positioning and Competitive Advantage

Schneider Electric’s position as a global leader in energy management and electrical distribution provides unique advantages for TH110 deployment and market acceptance. The company’s extensive installed base of switchgear, transformers, and distribution equipment creates natural integration opportunities for thermal monitoring systems. This market position enables Schneider to offer comprehensive solutions that combine electrical infrastructure with advanced monitoring capabilities.

The growing emphasis on Industry 4.0 and IoT integration across industrial sectors creates expanding demand for smart monitoring solutions. The global smart grid market, projected to exceed $130 billion by 2028, represents a significant opportunity for thermal monitoring technologies. Similarly, the wireless sensor market is expected to reach $40 billion by 2028, with compound annual growth rates exceeding 18.5%, indicating strong market acceptance of wireless monitoring solutions.

Technical Innovation and Industry Leadership

Addressing Traditional Monitoring Limitations

Conventional thermal monitoring approaches, primarily periodic infrared thermography, suffer from significant limitations that the TH110 directly addresses. Traditional IR surveys require physical access to equipment, creating safety risks for technicians working around energized systems. The need to open electrical panels for inspection introduces arc flash hazards and requires system shutdowns that disrupt operations and reduce productivity.1684808226198.jpgyoutube

Periodic inspections, typically conducted quarterly or annually, can miss rapidly developing problems that occur between survey intervals. Equipment failures often progress quickly once initiated, making continuous monitoring essential for early problem detection. The TH110’s continuous operation provides 24/7 vigilance that captures temperature changes as they develop, enabling intervention before conditions become dangerous.

Weather conditions, accessibility limitations, and human factors can affect the quality and consistency of traditional infrared inspections. The TH110 eliminates these variables by providing automated, standardized measurements under all operating conditions. This consistency ensures that developing problems are detected regardless of external factors that might compromise manual inspection effectiveness.

Supporting Digital Transformation Initiatives

The TH110 supports broader digital transformation initiatives across industrial and commercial sectors by providing essential data for digital twin applications, predictive analytics, and automated control systems. As organizations increasingly adopt IoT-enabled operations, thermal monitoring data becomes crucial input for comprehensive system optimization and predictive maintenance programs.

Integration with cloud-based analytics platforms enables sophisticated data analysis that would be impossible with standalone monitoring systems. Machine learning algorithms can identify subtle patterns in thermal behavior that indicate developing problems, equipment inefficiencies, or optimization opportunities. This analytical capability transforms thermal monitoring from simple alarm generation to strategic operational intelligence.

Wireless temperature and humidity monitoring system for industrial cold rooms showing real-time data on a tablet and sensor device

The TH110’s wireless communication capabilities support the decentralized monitoring architectures required for modern industrial IoT implementations. By eliminating wiring requirements and enabling flexible sensor placement, the TH110 facilitates monitoring system expansion and reconfiguration as operational needs evolve. This flexibility is essential for organizations adapting to changing business requirements and technological advances.

Applications Across Critical Infrastructure

Medium Voltage Switchgear Protection

Medium voltage switchgear represents one of the most critical applications for TH110 thermal monitoring due to the high energy levels involved and the catastrophic consequences of failures. In MV applications, loose connections or deteriorating contacts can create conditions where thousands of amperes generate dangerous heat levels within minutes. The TH110’s ability to monitor cable connections, busbar joints, and circuit breaker contacts provides comprehensive protection for these critical components.

The sensor’s 52kV voltage tolerance and 5000A current capacity ensure safe operation in high-energy electrical environments typical of industrial and utility installations. Installation on both shielded and unshielded components enables monitoring of critical connection points that are often inaccessible for traditional inspection methods. The wireless communication capability eliminates the need for additional wiring that could compromise electrical clearances or create new failure modes.

Factory installation of TH110 sensors in new Schneider Electric switchgear ensures optimal placement and integration with equipment control systems. For existing installations, retrofit services enable thermal monitoring upgrades that enhance safety and reliability without requiring equipment replacement. This flexibility makes TH110 technology accessible across the entire installed base of electrical distribution equipment.

Transformer and Power Generation Monitoring

Power transformers represent critical infrastructure components where failure can affect thousands of customers and cost millions of dollars in replacement equipment and lost productivity. The TH110 enables monitoring of transformer connections, tap changers, and cooling system components to detect developing problems before they cause outages or equipment damage. Early detection of insulation degradation, connection heating, or cooling system problems enables preventive maintenance that extends transformer life and improves system reliability.

In power generation applications, the TH110 monitors generator connections, switchyard equipment, and power transmission components where thermal problems can cascade into grid-wide disturbances. The sensor’s energy harvesting capability ensures operation during all system conditions, including startup, normal operation, and emergency configurations. This reliability is essential for critical infrastructure protection where monitoring systems must function under all operating scenarios.

Data Center and Critical Facility Protection

Data centers represent high-value applications where electrical failures can result in service outages affecting millions of users and generating massive economic losses. The TH110’s precision monitoring capabilities enable detection of thermal problems in power distribution equipment, backup power systems, and cooling infrastructure before they compromise facility operations. Continuous monitoring supports the high availability requirements of modern data centers where even brief outages can have significant consequences.

The integration with EcoStruxure IT platforms provides data center operators with comprehensive visibility into electrical system health, supporting predictive maintenance programs that maximize uptime while minimizing operational costs. Real-time thermal monitoring enables dynamic load management and proactive maintenance scheduling that maintains service availability while optimizing energy efficiency and equipment life.

Safety Enhancement and Risk Mitigation

Personnel Protection Through Remote Monitoring

The TH110’s wireless operation eliminates the need for personnel to work around energized equipment for routine thermal monitoring, significantly reducing arc flash exposure and other electrical hazards. Technicians can access real-time thermal data remotely, enabling condition assessment without physical proximity to dangerous electrical equipment. This capability is particularly valuable in high-voltage applications where even routine maintenance activities pose significant safety risks.

Automated alerting systems notify maintenance personnel of developing thermal problems, enabling planned maintenance during safe, de-energized conditions rather than emergency repairs under hazardous circumstances. This proactive approach reduces both the frequency and severity of maintenance work exposure while improving overall system reliability and safety performance.

Regulatory Compliance and Standards Adherence

Electrical safety regulations worldwide increasingly emphasize preventive maintenance and risk assessment approaches that favor continuous monitoring over periodic inspection methods. The TH110 supports compliance with evolving safety standards by providing documented evidence of thermal monitoring and maintenance decision-making processes. Automated data logging and trend analysis capabilities support regulatory reporting requirements while demonstrating due diligence in equipment safety management.

Insurance providers increasingly recognize the value of continuous monitoring systems in reducing claim frequency and severity, potentially offering premium reductions for facilities with comprehensive thermal monitoring programs. The TH110’s documented performance in preventing electrical failures provides quantifiable risk reduction that supports both regulatory compliance and insurance optimization strategies.

Future-Proofing Electrical Infrastructure

Adaptation to Changing Energy Landscape

The global transition toward renewable energy sources, electric vehicle infrastructure, and distributed generation creates new challenges for electrical system monitoring and protection. These emerging technologies often operate with variable loading patterns and power quality characteristics that differ from traditional electrical systems. The TH110’s continuous monitoring capability provides essential visibility into thermal behavior under these dynamic operating conditions.

Smart grid implementations require distributed monitoring capabilities that support real-time system optimization and automated response to changing conditions. The TH110’s integration with IoT platforms enables participation in smart grid applications where thermal data contributes to system-wide optimization, demand response programs, and grid stability management. This capability positions thermal monitoring as a fundamental component of modern electrical infrastructure rather than a supplementary safety system.

Scalability and System Integration

The TH110’s wireless architecture and cloud connectivity enable scalable monitoring implementations that can grow from single installations to enterprise-wide programs encompassing thousands of monitoring points. This scalability supports organizational growth and changing monitoring requirements without requiring fundamental system redesign or major infrastructure investments. The modular approach enables cost-effective expansion and adaptation to evolving operational needs.

Integration with existing building management systems, SCADA networks, and enterprise resource planning systems enables thermal monitoring data to contribute to comprehensive facility optimization programs. This integration transforms thermal monitoring from isolated safety systems into strategic operational tools that support efficiency improvement, predictive maintenance, and risk management across entire organizations.

The Strategic Imperative

Schneider Electric’s development of the TH110 wireless thermal sensor represents far more than a product line extension—it embodies a strategic response to fundamental challenges facing modern electrical infrastructure. The convergence of increasing electrical system complexity, escalating safety requirements, economic pressures for operational efficiency, and technological opportunities for intelligent monitoring creates compelling justification for this innovative technology.

The statistical evidence of electrical fire risks, combined with documented benefits of predictive maintenance and continuous monitoring, provides clear economic and safety justification for TH110 deployment across critical electrical infrastructure. As organizations worldwide grapple with aging electrical systems, increasing energy demands, and evolving safety standards, the TH110 offers proven solutions that address immediate needs while supporting future technological evolution.

The wireless, maintenance-free design eliminates traditional barriers to comprehensive thermal monitoring deployment, making advanced protection accessible across diverse applications and organizational scales. Integration with Schneider Electric’s broader EcoStruxure ecosystem ensures that thermal monitoring contributes to comprehensive operational optimization rather than functioning as an isolated safety system.

For Schneider Electric, the TH110 represents successful innovation that combines technical excellence with market leadership, creating competitive advantages while advancing industry safety standards. The product’s success validates the company’s strategic focus on digital transformation and IoT-enabled solutions that address real-world challenges with practical, cost-effective technologies.

The TH110’s importance extends beyond immediate safety benefits to encompass strategic positioning for the future of electrical infrastructure. As the energy landscape continues evolving toward greater electrification, renewable integration, and digital control, continuous thermal monitoring will become increasingly essential for system reliability, efficiency, and safety. Schneider Electric’s early investment in this technology establishes market leadership while contributing to the broader advancement of electrical infrastructure capabilities worldwide.