Introduction

Industrial Automation Trends 2026: What’s New in Smart Factories? This question is top of mind for manufacturers as rapid advancements in AI, robotics, IIoT, and automation software redefine how modern factories operate. As industries push toward greater efficiency, accuracy, and sustainability, 2026 is shaping up to be a transformative year for smart manufacturing. In this blog post, we break down the latest innovations, emerging technologies, and evolving strategies that are powering the next generation of smart factories—helping businesses stay competitive in a fast-changing industrial landscape.

1. AI-Driven Automation Takes Center Stage

Artificial intelligence is no longer optional—it has become the backbone of modern industrial automation. In 2026, AI is powering real-time quality checks, forecasting equipment failures, and optimizing production schedules automatically.

What’s new in 2026?

- AI copilots for machine operators

- Autonomous process adjustments based on live sensor data

- Smarter anomaly detection with fewer false alarms

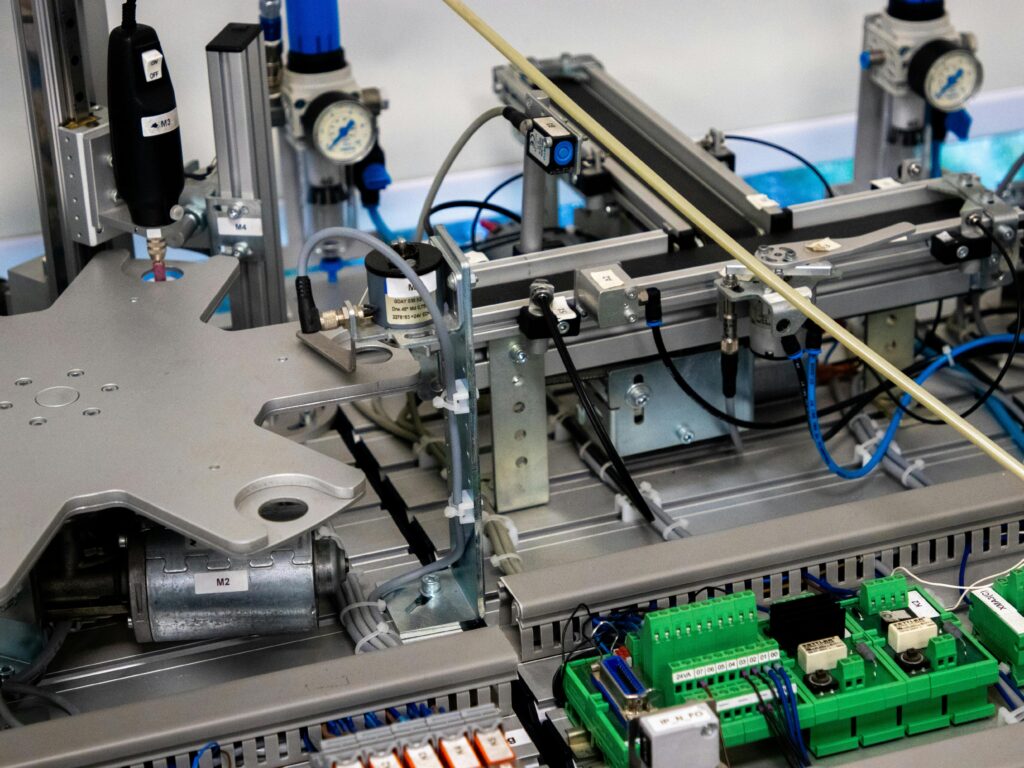

2. Next-Gen Robotics: Cobots, AMRs & Autonomous Workcells

Robots in 2026 are more collaborative, mobile, and intelligent. Cobots work safely alongside humans, and AMRs navigate freely on shop floors to eliminate manual transport.

What’s new in smart factories?

- AI-powered cobots that learn tasks faster

- Vision-enabled robots for complex pick-and-place

- Autonomous robotic workcells that configure themselves

3. IIoT and Hyper-Connected Sensor Ecosystems

The Industrial Internet of Things (IIoT) continues to expand with ultra-fast wireless networks and smarter sensors.

New trends in 2026 include:

- 5G/6G-enabled machine connectivity

- Edge sensors with built-in AI

- Self-calibrating and self-healing sensor networks

This connectivity creates a digital nervous system for smart factories.

4. Digital Twins Become Industry Standard

Digital twins are now used across the entire manufacturing lifecycle—design, testing, optimization, and maintenance.

In 2026, they offer:

- Real-time mirroring of machine states

- Virtual commissioning to reduce downtime

- Predictive simulation of production outcomes

Factories use digital twins to experiment virtually before making real-world changes.

5. Edge Computing Overtakes Cloud for Real-Time Automation

As factories demand faster response times, edge computing is becoming essential.

Trends driving adoption:

- Ultra-low latency for robotics

- Local data processing to reduce cloud dependency

- Enhanced data privacy and cybersecurity

Still, cloud systems remain important for analytics and long-term data storage.

6. Stronger Cybersecurity for Smart Factories

With more connectivity comes higher cyber risks. In 2026, cybersecurity is integrated directly into automation equipment.

Latest advancements:

- Zero-trust security frameworks

- AI threat detection

- Encrypted communication for PLCs and HMIs

Industrial networks are becoming as secure as IT networks.

7. Autonomous Production Lines & Lights-Out Manufacturing

The dream of fully automated “lights-out factories” is getting closer.

What’s new in 2026?

- Lines that dynamically adjust workflows

- Machines performing self-diagnostics

- Automated material handling from start to finish

Some industries—electronics and automotive—are already piloting complete autonomous shifts.

8. Sustainability-Driven Automation

Sustainable automation is now a priority, driven by global regulations and rising energy costs.

Sustainability trends include:

- Smart energy monitoring

- Low-carbon manufacturing equipment

- Waste reduction through AI-driven optimization

Modern smart factories aim to minimize environmental impact while maximizing production output.

9. Unified Industrial Software Platforms

Manufacturers are moving away from siloed systems and adopting unified software ecosystems.

In 2026, these platforms offer:

- Centralized monitoring of machines and workflows

- Low-code tools for automation configuration

- Seamless integration of ERP, MES, SCADA, and IIoT

This enables faster decision-making and better collaboration across departments.

10. AR/VR and Workforce Augmentation

The smart factory workforce is evolving—not being replaced. AR/VR tools empower workers with real-time data and immersive training.

What’s new in 2026?

- AR glasses displaying live machine diagnostics

- VR simulations for safe technical training

- Digital assistants guiding new hires

Together, these tools make employees more skilled and productive.

Conclusion

As we look ahead, it’s clear that Industrial Automation Trends 2026: What’s New in Smart Factories? is more than just a question—it’s a roadmap for the future of manufacturing. The technologies reshaping factories today are making operations faster, smarter, safer, and far more efficient. From AI-driven automation and hyper-connected IIoT systems to autonomous production lines and sustainable manufacturing practices, 2026 marks a major turning point for industrial innovation.

Smart factories are no longer simply adopting automation—they are evolving into intelligent ecosystems capable of learning, adapting, and optimizing themselves in real time. Companies that embrace these advancements early will gain a significant competitive edge through lower costs, higher productivity, and improved quality.