“Siemens ET200 vs Allen-Bradley POINT I/O comparison for 2025. Understand features, communication protocols, cost, performance, installation and best use cases.”

Distributed I/O systems play a crucial role in modern industrial automation, especially in smart factories where efficiency, modularity and real-time communication are essential. Today, two of the most widely used systems are the Siemens ET200 family and the Allen-Bradley POINT I/O platform. Both are reliable, compact and compatible with advanced PLC systems—but each has strengths that suit different industries and applications.

In this detailed comparison, we cover features, performance, pricing, protocols, ease of installation, scalability, and best use cases. This guide will help you choose the right system for your industrial project in 2025.

1. Overview of Both Systems

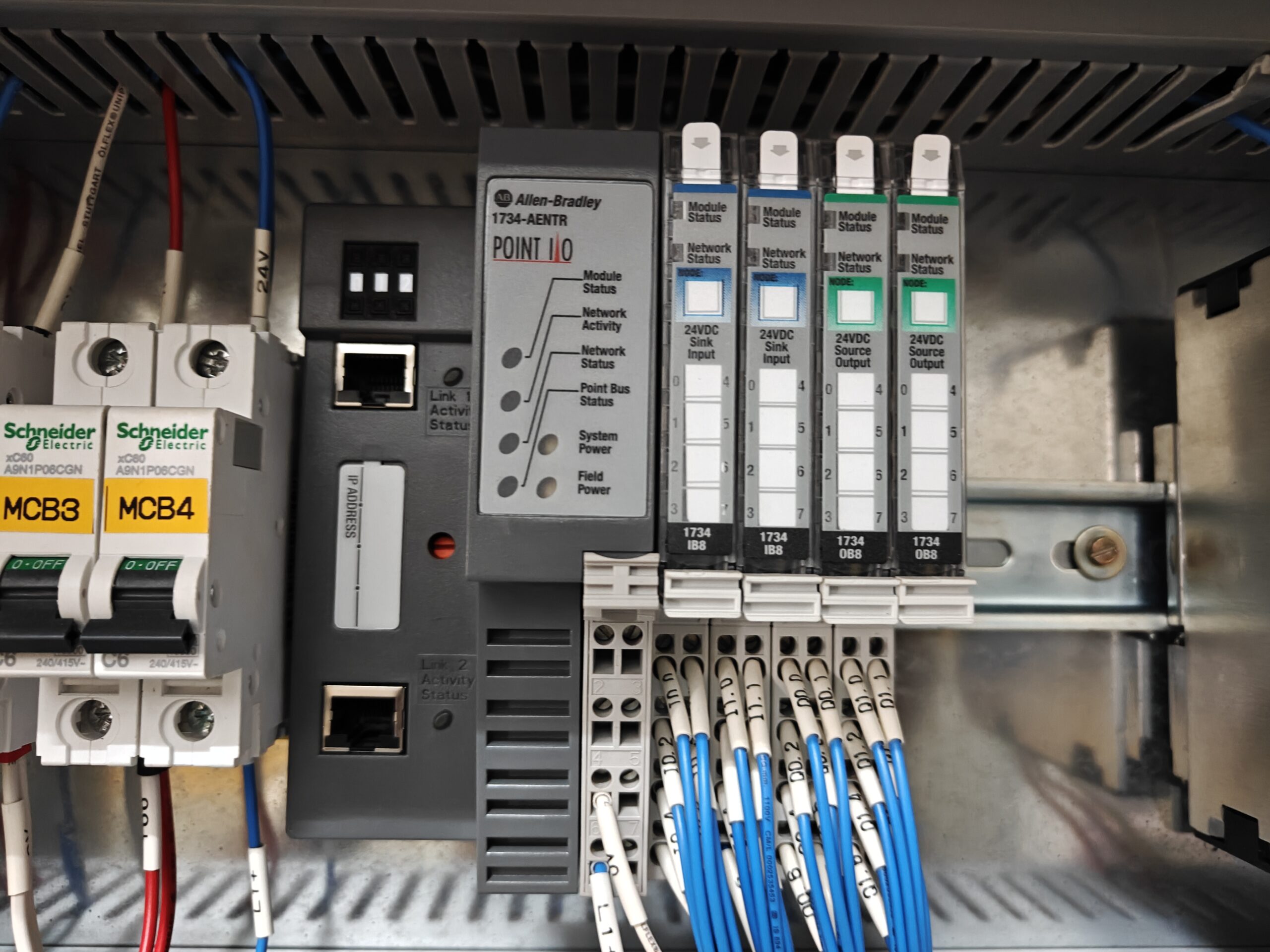

Allen-Bradley POINT I/O

- Brand: Rockwell Automation

- Focus: Modular distributed I/O

- Communication: Ethernet/IP

- Known for: Compact size, integration with Logix PLCs, strong diagnostics

- Best for: Industries using CompactLogix or ControlLogix PLCs

Siemens ET200 Family

- Brand: Siemens

- Focus: Wide distributed I/O platform (ET200S, ET200SP, ET200MP)

- Communication: PROFINET / PROFIBUS

- Known for: High performance, rugged design, flexible I/O options

- Best for: Siemens PLC users (S7-1200, S7-1500)

2. System Architecture Comparison

| Feature | Siemens ET200 | Allen-Bradley POINT I/O |

|---|---|---|

| Form Factor | Compact, modular | Ultra-compact modular |

| Mounting | DIN rail | DIN rail |

| Expansion | Up to 64+ modules | Up to 63 modules |

| Power Distribution | Strong, multiple base modules | Terminal base with integrated bus |

| I/O Density | High-density options | Mainly low–medium density |

| Hot Swapping | Yes | Yes |

Winner: Tie

Both systems offer strong modular architectures, but POINT I/O is slightly more compact, while ET200 offers more variations and density.

3. Communication Protocol Comparison

| Protocol | Siemens ET200 | Allen-Bradley POINT I/O |

|---|---|---|

| PROFINET | ✔ Supported | ✖ Not supported |

| PROFIBUS | ✔ Supported | ✖ Not supported |

| Ethernet/IP | ✖ Not supported | ✔ Fully supported |

| DLR Support | ✔ (ET200SP) | ✔ (1734-AENTR) |

| OPC UA | ✔ (with modules) | ✔ (via PLC gateway) |

Winner: Depends on PLC brand

- If you use Siemens PLCs, ET200 is the clear winner.

- If you use Allen-Bradley PLCs, POINT I/O is the best choice.

4. Installation & Wiring Comparison

Allen-Bradley POINT I/O

- Very compact

- Snap-on terminal bases

- Fast wiring & labeling

- Minimal panel space needed

Siemens ET200

- Wider range of terminal modules

- Clean wiring arrangement

- Strong mechanical design

Winner: Allen-Bradley POINT I/O

POINT I/O saves more space, uses fewer terminals, and is faster to install in small panels.

5. Diagnostics & Troubleshooting

Siemens ET200

- Advanced PROFINET diagnostics

- Detailed fault messages

- Module-level and channel-level alarms

- TIA Portal integration

Allen-Bradley POINT I/O

- Clear LED indicators

- Built-in web diagnostics (AENTR)

- Quick link to Studio 5000

Winner: Siemens ET200

Diagnostics in Siemens ET200 are deeper and more detailed through TIA Portal.

6. Software Environment Comparison

| Criteria | Siemens ET200 (TIA Portal) | Allen-Bradley POINT I/O (Studio 5000) |

|---|---|---|

| Ease of Use | Medium | Easy |

| Learning Curve | Steep | Moderate |

| Library Support | Excellent | Good |

| Device Integration | Very strong | Very strong |

Winner: Depends on experience

- TIA Portal is powerful but complex.

- Studio 5000 is more user-friendly for beginners.

7. Reliability & Industrial Performance

Siemens ET200

- Designed for harsh environments

- Better temperature and vibration tolerance

- Industry-leading reliability

Allen-Bradley POINT I/O

- Highly reliable

- Ideal for machine-level automation

- Strong performance for small/medium applications

Winner: Siemens ET200

ET200 is more rugged and better suited for heavy-duty industrial environments.

8. Cost Comparison (2025)

| Cost Factor | Siemens ET200 | Allen-Bradley POINT I/O |

|---|---|---|

| Module Cost | Higher | Moderate |

| Adapter/Head Module | Higher | Lower |

| Engineering Time | Slightly higher | Lower |

| Overall Project Cost | Higher | Medium |

Winner: Allen-Bradley POINT I/O

POINT I/O is generally more cost-effective, especially for small-to-medium systems.

9. Best Use Cases

Siemens ET200 – Best For

- Large industrial plants

- Harsh environments

- High-speed automation

- PROFINET/Siemens PLC-based systems

- Complex process automation

Allen-Bradley POINT I/O – Best For

- OEM machinery

- Compact control panels

- Distributed machine I/O

- Ethernet/IP networks

- Rockwell PLC systems

Final Verdict: Which One Is Better?

The choice depends entirely on your PLC ecosystem and application requirements:

✔ Choose Siemens ET200 if:

- You are using Siemens S7-1200 or S7-1500 PLCs

- You need high performance and rugged design

- You require PROFINET/PROFIBUS support

- You want advanced diagnostics

✔ Choose Allen-Bradley POINT I/O if:

- You use CompactLogix or ControlLogix PLCs

- You need compact, space-saving I/O

- You want easy installation and lower cost

- Your system is mostly machine-level automation